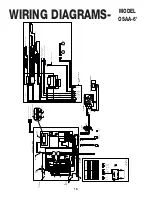

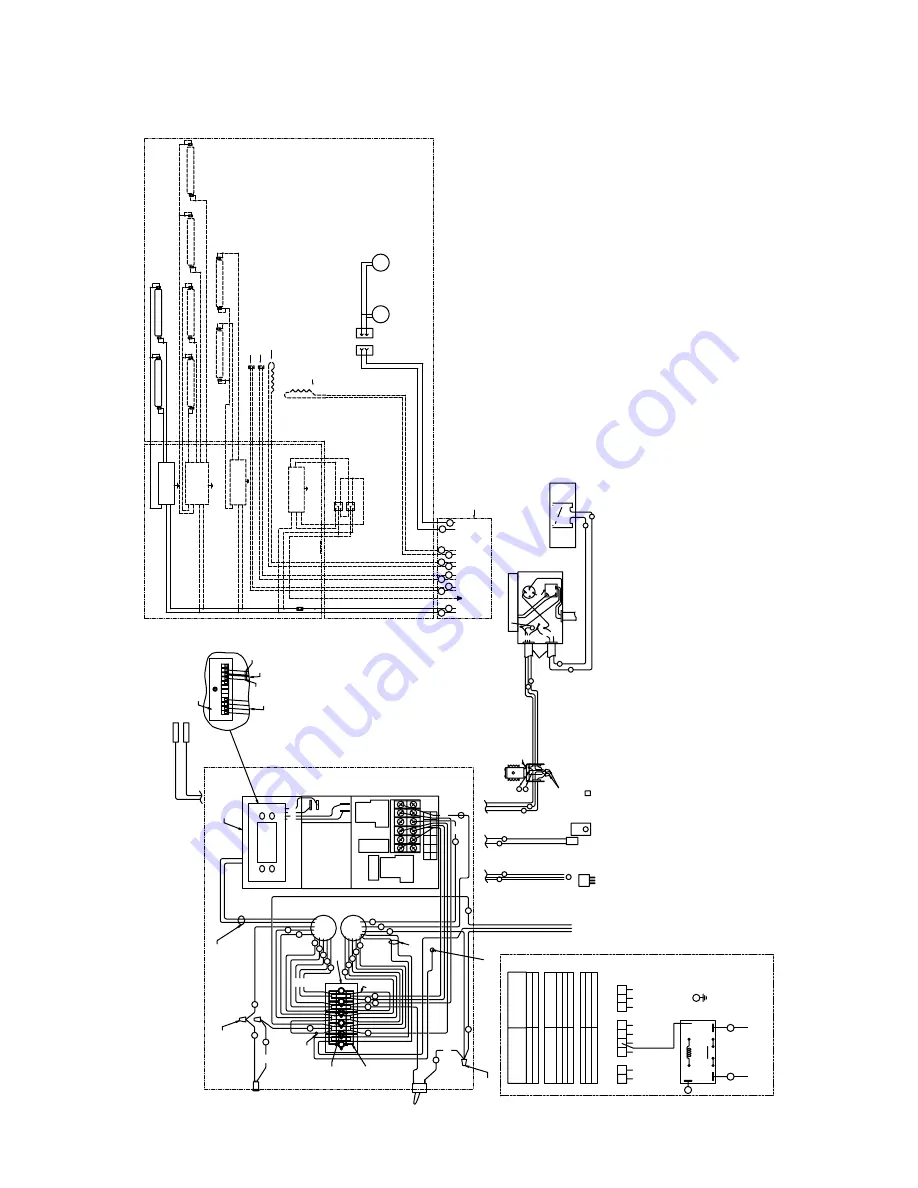

HTR1

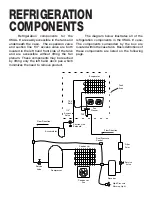

FAN MOTOR

J3

P3

FAN MOTOR

M1

M2

HTR2

SHELF LIGHTS (OPTIONAL)

DEF. TERM. CONTROL (OPTIONAL)

TEMP. CONTROL (OPTIONAL)

FRONT GLASS ANTI-COND HEATER

DEFROST HEATERS (OPTIONAL)

13

12

11

21

23

20

14

19

4

L1

L2

3

RED

BLK

EB6

WHT

BLK

EB6

WHT

RED

BLU

BLU

BLU

BLU

EB2

EB1

YEL

BLK

YEL

WHT

WHT

BLK

RED

RED

BLU

RED

BLU

BLU

BLU

J2-2

J2-1

BLUE

BLUE

NOSE LIGHTS

L7

L8

L3

L1

L4

L2

L5

(OPTIONAL)

L6

GREEN

WHITE

RED

RED

BLACK

WHITE

WHITE

BLACK

PURPLE

YELLOW

WHITE

BLACK

YELLOW

BLACK

WHITE

BLACK

CONDENSING UNIT J-BOX

BL

K

BLK

B

LK

CONTROL J-BOX

G

R

N

W

H

T

B

L

K

BLU

11

12

14

24

22

21

WIRE

CAPS

(3)

WIRE

CAPS

GROUND

SCREW

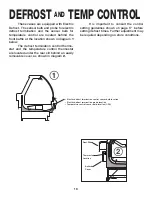

BACK OF CONTROL MODULE

WIRES FROM PROBES

WIRES FROM POWER MODULE

CONTROL

MODULE

DEFROST

PROBE

TEMP

PROBE

PROBES

WIRE

CAPS

(2)

WIRE

CAP

NEUTRAL

JUMPER

(WHITE)

NEUTRAL

TERMINAL

BLOCKS

HOT

TERMINAL

BLOCKS

HOT

JUMPER

(BLACK)

BLK

BLK

BLK

BLK

BLK

GRN

BLK

BLK

GROUND

TERMINAL

BLOCK

CHASSIS

GROUND

{

HEATERS

COMP. ROOM

COMP. ROOM

120V LIGHTS

{

ANTI-COND.

TO

TO

{

{

BLACK

GREEN

BLACK

WHITE

YELLOW

YELLOW

OPT DEFROST

120V FANS

208/240V

120V

{

{

WHITE

RED

BLUE

SW1

PURPLE

RED

TEMP PROBE (LOCATION- RETURN AIR)

DEFROST PROBE (LOCATION- COIL)

SOLENOID

VALVE COIL

DRAIN

PAN

RECEPTACLE

DUAL PRESSURE SWITCH

S2

V1

BL

UE

02

01

V2

GR

EE

N

RE

D

WH

ITE

D

S1

SC

AC PLUG

FNC

ALM

FNO

L2

V2

V1

02

01

CP2

CP1

240

120

DH2

DH1

S

E

R

V

IC

E

L

IG

H

T

(H

I P

R

E

S

S

U

R

E

)

32

33

48

47

38

52

39

47

48

51

51

52

RE

D

RE

D

WH

ITE

WH

ITE

SUCTION LINE

GROUND

SCREW

CONDUIT

TO CONTROL J-BOX

FANS

TO CONTROL J-BOX

CONDENSING UNIT

WHITE

RED

GREEN

BLUE

POWER SWITCH

SW1

49

50

4

14

32

50

12

2

49

33

47

3

1

13

11

42

58

58

53

54

53

2

48

16

15

WIRING

HOLE

WIRING

HOLE

HI

PRESSURE

SWITCH

57

42

42

42

48

57

REAR SILL

INSIDE CASE

PRIMARY CORNICE LIGHTING

TWO ROW CORNICE LIGHTING (OPTIONAL)

CONNECT CONDENSING

CPC-ESC3

CONVERSION

42

5

4

NEUTRAL

120VacH

48

HOT

GROUND

1

6

Compressor

120V Hot

Common

Amb temp

Def temp

Defrost

Common

Fan

120VacN

1

J4

JOHNSON CONTROL

J5

J6

J6-Defrost

J5-Common

J5-Def temp

J5-Amb temp

S1

S2

SC

DH2

J4-120Vac Neu In

J6-120V Hot

J6-Fan

J6-Compressor

Common

DH1

CP2

FNO

CP1

J4-120Vac Hot In

P061904A/P061905K

CPC

ESC3

P055258H

120

L2

MR4PMUHV

16

WIRING DIAGRAMS-

MODEL

OSAA-6’

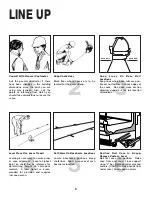

Summary of Contents for Origin2 OSAA

Page 1: ...DELI C A S E S MODEL OSAA HANDBOOK INSTALLATION OPERATION 9 03 P061773M...

Page 2: ......

Page 4: ......

Page 29: ...25 NOTES...

Page 30: ...26 NOTES...