C

ASE

C

ONNECTIONS

REFRIGERATION

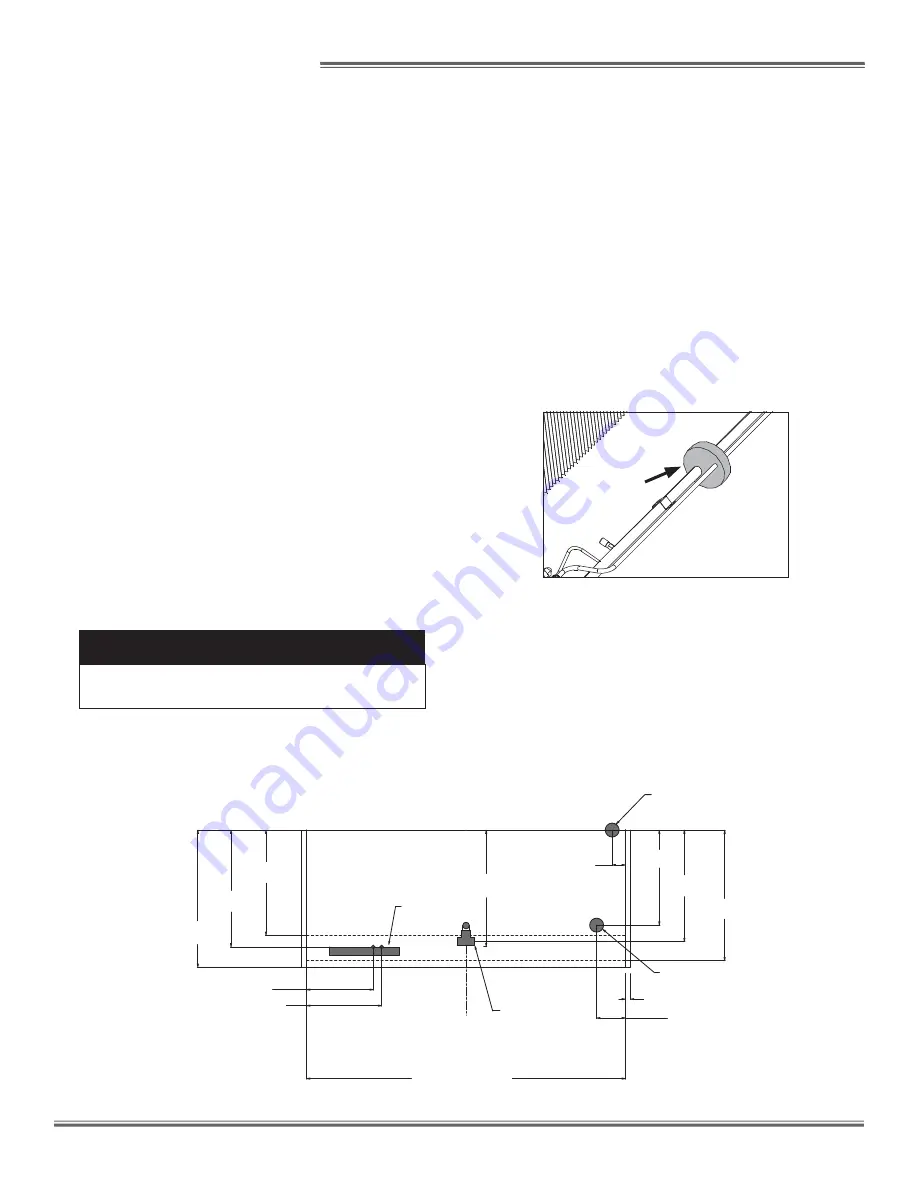

As the diagram below indicates, the coil outlet hole is

positioned forward on the right-hand side of the case, fully

visible in front of the fan plenum.

The expansion valve and other controls - located on the

left-hand side of the case - are accessible without lifting the

fan plenum and may be reached by lifting the deck pans.

If it becomes necessary to penetrate the case bottom, be

certain to seal it afterwards with canned-foam sealant and

white RTV.

PLUMBING

The drain outlet is specially molded out of PVC material

and is located in the center of the case for convenient ac-

cess. The “P” trap, furnished with the case, is constructed

of schedule 40 PVC pipe. Care should be given to ensure

that all connections are water-tight and sealed with the ap-

propriate PVC or ABS cement.

The drain lines can be run left or right of the tee with the

proper pitch to satisfy local drainage requirements. Since

the kickplate is shipped loose with the case, you should

have open access to the drain line area during installation.

35 1/16 in

[89.1 cm]

**

39 3/8 in

[99.9 cm]

41 5/16 in

[104.9 cm]

31 11/16 in

[80.5 cm]

FRONT OF CASE

C

L

1 1/2 in [3.8 cm] {END}

96 in [243.8 cm] (8' CASE)

8 11/16 in [22.1 cm]

4 in[10.2 cm]

28 5/8 in

[72.7 cm]

REFRIGERATION

REAR REFRIGERATION

(11 3/4" OFF OF FLOOR)

22 9/16 in [57.3 cm]

20 1/16 in [51.0 cm]

35 3/16 in

[89.4 cm]

JUNCTION BOX

(STANDARD)

ELECTRICAL

1 1/2" PVC DRAIN

CONNECTION

33 9/16 in

[85.3 cm]

MODEL

UPL-NRG

REMOVE THE SHIPPING BLOCKS THAT PROTECT THE

REFRIGERATION LINES DURING SHIPMENT BEFORE

OPERATING THE CASE.

REMOVE

If the kickplate has been installed, you will

fi

nd it very easy

to remove. Simply lift the kickplate up from the "J" rail and

pull it out, away from the case. See the Trim Out section

on page 6.

ELECTRICAL

Electrical hookups are made to a junction box located at

the bottom-left-front of the case.

For case-to-case wiring, run conduit between the junction

boxes. When connecting to the junction box on the bottom-

left side of the case,

fi

eld wiring should exit box from the

right side (furthest away from case wiring) to allow more

room inside for wiring connections.

C A U T I O N

If any brazing is necessary, place wet rags

around the area to avoid tank damage.

▲

7

Summary of Contents for UPL-NRG

Page 2: ...ii...

Page 15: ...APPENDIX A WIRING DIAGRAMS...

Page 16: ......

Page 17: ...NOTES...

Page 18: ...NOTES...