A

IRFLOW

, D

EFROST

& T

EMP

C

ONTROLS

case on the bottom-left side (Fig. 5). To access the thermo-

stats, you must first remove the kick plate, then remove the

junction box cover. For instructions on removing the kick-

plate, see the Trim Out section of this manual on page 6.

It is important to consult the control setting guidelines shown

on page 2 before setting defrost times. Further adjustment

may be required depending on store conditions.

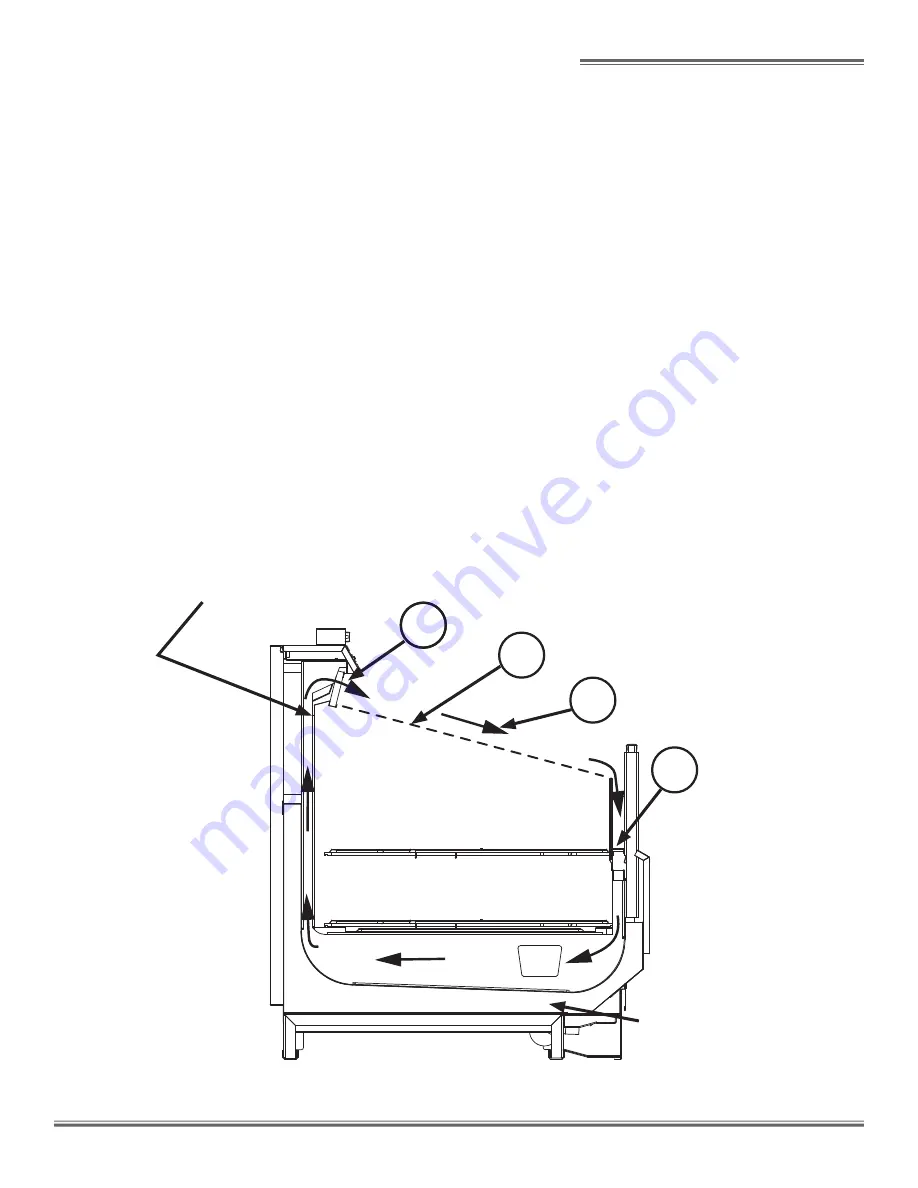

AIR FLOW & PRODUCT LOAD

Hill PHOENIX cases provide maximum product capacity

within the refrigerated air envelope. Please keep products

within the load limit line shown on the diagram below.

It is important that you do not overload the food product dis-

play so that it impinges on the air

fl

ow pattern. Overloading

will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections

are covered.

DEFROST & TEMPERATURE CONTROLS

UPL-NRG cases are equipped with Timed-Off defrost.

The rear baffle (Fig. 5) contains the sensor bulb for tem-

perature control and the discharge air probe. The defrost

termination control thermostat and the temperature control

thermostat are located in the junction box underneath the

Fig. 5 Airflow; probe, sensor locations.

Temperature control sensor bulb

Discharge air probe

Defrost termination control thermostat

Temperature control thermostat

MODEL

UPL-NRG

1. DISCHARGE AIR

2. LOAD LIMIT

3. AIR CURTAIN

4. RETURN AIR

1

1

2

3

4

8

Summary of Contents for UPL-NRG

Page 2: ...ii...

Page 15: ...APPENDIX A WIRING DIAGRAMS...

Page 16: ......

Page 17: ...NOTES...

Page 18: ...NOTES...