T

hank you for choosing Hill PHOENIX for your food merchandising needs. This handbook contains important technical

information and will assist you with the installation and operation of your new Hill PHOENIX display cases. By closely fol-

lowing the instructions, you can expect peak performance; attractive fit and finish; and long case life.

We are always interested in your suggestions for improvements (e.g. case design, technical documents, etc.). Please feel

free to contact our Marketing Services group at the toll-free number listed below. Thank you for choosing Hill PHOENIX,

and we wish you the very best in outstanding food merchandising.

G

ENERAL

I

NFORMATION

CASE DESCRIPTION

This manual specifically covers the UPL-NRG single-deck

produce merchandiser.

STORE CONDITIONS

Hill PHOENIX cases are designed to operate in an air-con-

ditioned store that maintains a 75°F (24°C) store tempera-

ture and 55% (max) relative humidity (CRMA conditions).

Case operation will be adversely affected by exposure to

excessively high ambient temperatures and/or humidity.

REFRIGERATION SYSTEM OPERATION

Air-cooled condensing units require adequate ventilation

for efficient performance. Machine-room temperatures

must be maintained at a minimum of 65°F in winter and a

maximum of 95°F in summer. Minimum condensing tem-

peratures should be no less than 70°F.

RECEIVING CASES

Examine fixtures carefully and in the event of shipping

damage and/or shortages, please contact the Service

Parts Department at the toll-free number listed below.

CASE DAMAGE

Claims for obvious damage must be 1) noted on either the

freight bill or the express receipt and 2) signed by the carri-

er's agent; otherwise, the carrier may refuse the claim. If

damage becomes apparent after the equipment is

HILL PHOENIX

1925 Ruffin Mill Rd.

Colonial Heights, VA 23834

Mon.-Fri. (8 a.m to 5 p.m EST)

Tel: 1-800-283-1109/Fax: 804-526-7450

Web site: www.hillphoenix.com

unpacked, retain all packing materials and submit a written

request to the carrier for inspection within 14 days of

receipt of the equipment.

LOST/MISSING ITEMS

Equipment has been carefully inspected to insure the high-

est level of quality. Any claim for lost/missing items must

be made to Hill PHOENIX within 48 hours of receipt of the

equipment.

TECHNICAL SUPPORT

For technical questions regarding display cases, please

contact our Case Division Customer Service Department at

the toll-free number listed below. For questions regarding

our refrigeration systems or electrical distribution centers,

please contact our Systems Division Customer Service

Department at 1-770-388-0706.

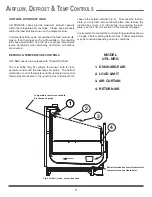

CONTACTING THE FACTORY

If you need to contact Hill PHOENIX regarding a specific

fixture, be certain that you have both the case model num-

ber and serial number (this information can be found on

the serial plate, located on the upper top flue panel on the

right-hand side). When you have this information, call the

toll-free number below and ask for a Service Parts

Representative.

4

Summary of Contents for UPL-NRG

Page 2: ...ii...

Page 15: ...APPENDIX A WIRING DIAGRAMS...

Page 16: ......

Page 17: ...NOTES...

Page 18: ...NOTES...