4.4 Tie Rod Assembly

Chapter 4: Removal, Replacement, and Adjustment Procedures

Page 4 - 8

TRANS

l

LIFT

TM

Resident Stand Assist Service Manual (man173)

4

4.4

Tie Rod Assembly

Tools required:

Socket head wrench

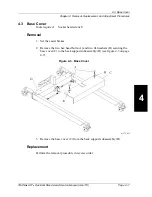

Removal

CAUTION:

Lay a sheet or other protective cloth on the floor before turning the unit

on its back. Failure to do so could result in equipment finish damage.

1. Lay a sheet or other protective cloth on the floor. Place the unit on its back.

2. Remove the base cover (refer to procedure 4.3).

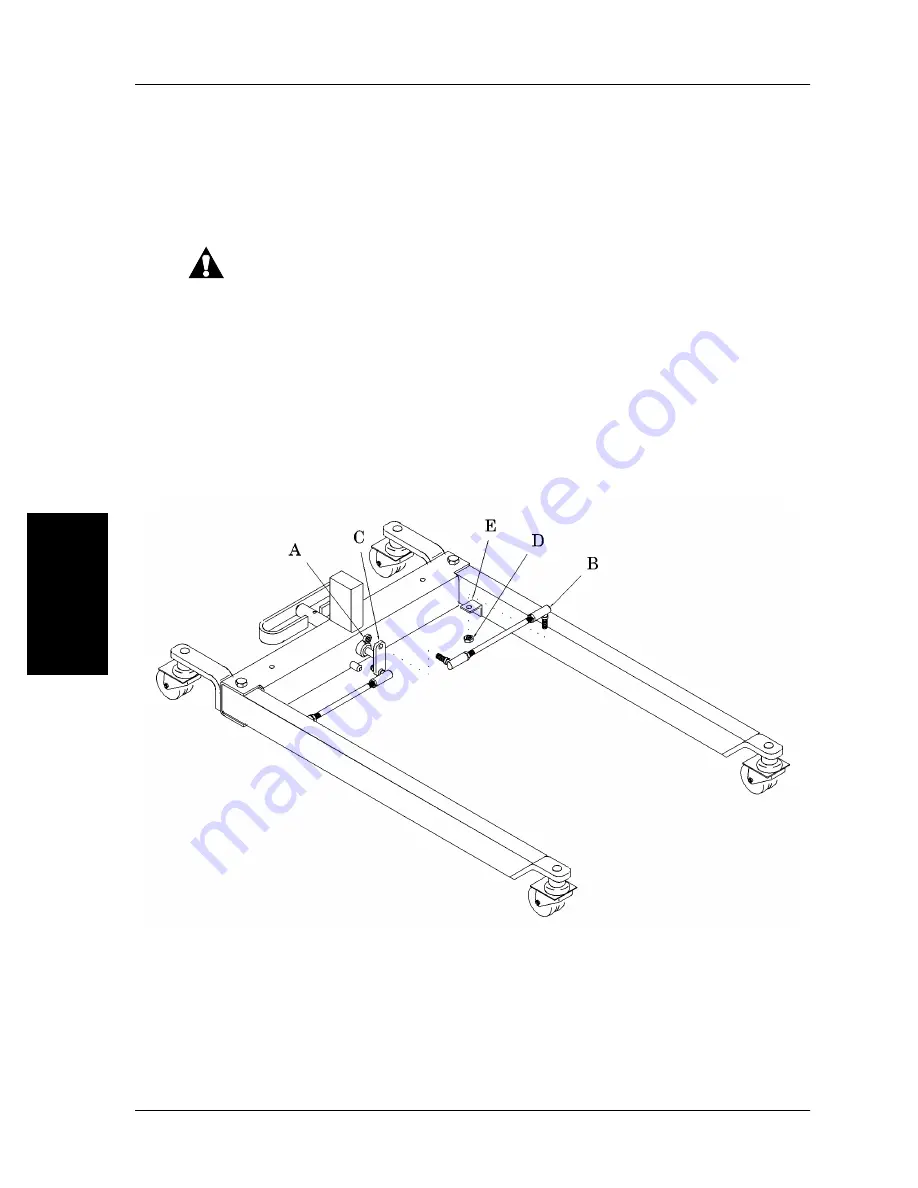

3. Remove the hex nut (A) securing the tie rod assembly (B) to the spreader

shaft subassembly (C) (see figure 4-4 on page 4-8).

Figure 4-4. Tie Rod Assembly

4. Remove the hex nut (D) securing the tie rod assembly (B) to the leg

subassembly (E).

5. Remove the tie rod assembly (B).

m173_012