CASE CLEANING

A periodic cleaning schedule should be established to

maintain proper sanitation, insure maximum operating ef-

ficiency, and avoid the corrosive action of food fluids on

metal parts that are left on for long periods of time. We

recommend cleaning once a week. Further suggestions

for case cleaning include the following:

•

To avoid shock hazard, be sure all electrical power is

turned off before cleaning. In some installations, more

than one disconnect switch may have to be turned off

to completely de-energize the case.

•

All surfaces pitch downward to a deep-drawn drain

trough, funneling liquids to the front of the case where

the waste outlet is located for easy access. Check the

waste outlet to insure it is not clogged before starting

the cleaning process and avoid introducing water fast-

er than the case drain can carry it away.

•

To clean the LED luminaires, shut off the lights in the

case, then wipe the luminaires down with a soft, damp

cloth. Avoid using harsh or abrasive cleaners as they

may damage the lights. Be certain that the luminaires

are completely dry before re-energizing.

•

If any potentially harmful cleaners are used, be cer-

tain to provide a temporary separator (e.g., cardboard,

plastic wrap, etc.) between those cases that are being

cleaned and those that may still contain product.

•

Avoid spraying any cleaning liquids directly on the

electrical connections.

•

Allow cases to be turned off long enough to clean any

frost or ice from coil and pans.

•

Remove kickplate and clean underneath the case with

a broom and a long-handled mop. Use warm water

and a disinfecting cleaning solution when cleaning un-

derneath the cases.

Fig. 16 Single-piece fan plenum and coil cover

SINGLE PIECE FAN

PLENUM SWINGS

UP FOR EASY

CLEANING

FAN

PLENUM

COIL

FANS & CASE MAINTENANCE

FANS

The evaporator fans are equipped with 16-watt fan motors.

Motors have a counter-clockwise rotation when viewed

from the shaft end.

The fan blades are 8” in diameter and the fan blade pitch

is set during the assembly process. It is important that the

blade pitch be maintained as specified. Do not attempt a

field modification by altering the blades.

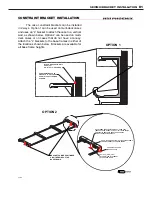

Fan motors may be changed with an easy two-step pro-

cess (Fig. 15) without lifting up the plenum, thereby avoid-

ing the necessity to unload the entire product display to

make a change:

1. Unplug the fan motor, easily accessible outside the

plenum. Push cord back through plenum opening.

2. Remove fasteners, then lift out the entire fan basket.

Reverse procedure when re-installing fan basket.

2

Fig. 15 Fan basket

1

CAUTION!

Exercise extreme caution when working in

a case with the coil cover removed. The

coil contains many sharp edges that can

cause severe cuts to the hands and arms.

ATTENTION!

Power cord must be pushed back through

the plenum opening before removing the

fan basket. Failure to do so may result in

damage to the power cord.

DANGER!

SHOCK HAZARD

Always disconnect power to case when

servicing or cleaning. Failure to do so

may result in serious injury or death.

9

Summary of Contents for 3NDML-NRG

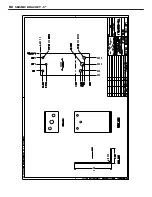

Page 16: ...BLUE WHITE BLACK 3NDML WIRING DIAGRAM B2 ...

Page 19: ...SEISMIC BRACKET 5 D2 ...

Page 20: ...SEISMIC BRACKET 7 D3 ...

Page 21: ...SEISMIC BRACKET 11 D4 ...

Page 22: ...SEISMIC BRACKET 15 D5 ...