IMPORTANT NOTICES

LIABILITY NOTICE

For Cases with Shelf Lighting Systems

Hillphoenix does NOT design any of its shelf lighting sys-

tems or any of its display cases with shelf lighting systems

for direct or indirect exposure to water or other liquids. The

use of a misting system or water hose on a display case

with a shelf lighting system, resulting in the direct or indirect

exposure of the lighting system to water, can lead to a num-

ber of serious issues (including, without limitation, electri-

cal failures, fire, electric shock, and mold) in turn resulting

in personal injury, death, sickness, and/or serious property

damage (including, without limitation, to the display itself,

to the location where the display is situated [e.g., store] and

to any surrounding property).

DO NOT use misting systems, water hoses or other devic-

es that spray liquids in Hillphoenix display cases with light-

ed shelves. If a misting system or water hose is installed

or used on a display case with a shelf lighting system, then

Hillphoenix shall not be subject to any obligations or liabili-

ties (whether arising out of breach of contract, warranty,

tort [including negligence], strict liability or other theories

of law) directly or indirectly resulting from, arising out of or

related to such installation or use, including, without limita-

tion, any personal injury, death or property damage result-

ing from an electrical failure, fire, electric shock, or mold.

P079211M, REVO

DANGER!

Indicates an immediate threat of serious

injury or death if all instructions are not fol-

lowed carefully.

CAUTION!

Indicates the potential threat of injury if all

instructions are not followed carefully.

ATTENTION!

Indicates an important point of information

that is key to ensuring proper case func-

tionality.

SERVICE NOTICE

To ensure proper functionality and optimum performance,

it is strongly recommended that Hillphoenix display cases

be installed/serviced by qualified technicians who have ex-

perience working with commercial refrigerated display mer-

chandisers and storage cabinets. For a list of Hillphoenix-

authorized installation/service contractors, please visit our

Web site at www.hillphoenix.com.

PRECAUTIONARY NOTICES

At Hillphoenix

®

, the safety of our customers and employ-

ees, as well as the ongoing performance of our products,

are top priorities. To that end, we call out important mes-

sages in all Hillphoenix installation and operations hand-

books with an accompanying alert symbol. All of these

notices are meant to provide information about potential

dangers to personal health and safety—as well as risks of

case damage—if the instructions are not carefully followed.

R-744 (CO2) NOTICE

For Systems Utilizing R-744 (CO2) Refrigerant

For refrigeration units that utilize R-744 (CO2), pressure

relief and pressure-regulating relief valves may need to be

installed based on the system capacity. The valves need

to be located such that no stop valve is positioned between

the relief valves and the parts or section of the system be-

ing protected.

When de-energizing refrigeration units containing R-744

(CO2), venting of the R-744 (CO2) refrigerant may occur

through the pressure regulating relief valves. These valves

are located on the refrigeration system and not on the case

model. If venting does occur, the valve must not be de-

feated, capped, or altered by any means.

GLYCOL NOTICE

For Systems Utilizing Glycol Refrigerant

Use of glycol as a secondary refrigerant must be carried

out in accordance with the procedures set forth in the Sec-

ond Nature Medium Temperature Secondary Refrigeration

Installation Manual, which is available for download at the

Hillphoenix website here:

http://goo.gl/JIWd77

Additionally, Hillphoenix uses and recommends Dow gly-

col-based coolants, which contain specially formulated in-

dustrial inhibitors that help to prevent corrosion in display

cases. Over time, the effectiveness of these inhibitors de-

teriorates, increasing the chance for corrosion. We rec-

ommend testing of glycol solutions annually through the

Dow lab. The service is free for systems containing over

250 gallons of glycol coolants, while the cost is approxi-

mately $100 for smaller systems. For more information,

see Dow’s DOWFROST and DOWFROST HD Guide here:

http://goo.gl/v6i1iQ

CAUTION!

Under no circumstance should any com-

ponent be replaced or added without

consulting Hillphoenix Field Service En-

gineering. Utilizing improper components

may result in serious injury to persons or

damage to the refrigeration system.

iii

Summary of Contents for 3NDML-NRG

Page 16: ...BLUE WHITE BLACK 3NDML WIRING DIAGRAM B2 ...

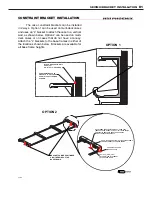

Page 19: ...SEISMIC BRACKET 5 D2 ...

Page 20: ...SEISMIC BRACKET 7 D3 ...

Page 21: ...SEISMIC BRACKET 11 D4 ...

Page 22: ...SEISMIC BRACKET 15 D5 ...