TRIM OUT

1.

Seal the case-to-case joints with caulk (supplied), then

apply acrylic tape (supplied) over the pipe-chase seam

(Fig. 3). The tape acts as a watershed preventing wa-

ter from settling in the case joint.

5.

Loosen the cornice joint at case end (cornice screws

are located on top of the case). Be certain that cornice

joints and pins are properly aligned. Cases are now

ready to be joined.

6.

Push the cases tightly together, then lightly bolt them

together through the holes that are provided (Fig. 2).

Tighten all the joining bolts until all margins are equal.

Be careful not to over tighten.

7.

Repeat steps 2-6 of this sequence for all remaining

cases. Be certain to properly level all cases.

8. If seismic brackets are included, see

Appendix D

for

detailed installation instructions.

CASE INSTALLATION

2.

Re-install shelves. Be aware that differing shelf con-

figurations will affect energy consumption and case

performance.

3.

Tighten all cornice joints as needed (Fig. 4). Working

outward from the center of the line-up, loosen the fas-

teners on the top and slide the cornices in one direction

so that each joint aligns tightly together. Tighten the

fasteners on top and apply an external joint band on

the extreme ends of the lineup if a gap exists.

4.

Properly align the front panels as needed, then install

the front panel trim (supplied).

5.

Attach the one-piece kick plate to the factory installed

kickplate retainers with the screws provided.

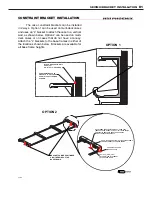

Fig. 3 Sealing the pipe chase

ACRYLIC

TAPE

PIPE

CHASE

ATTENTION!

Installation of 3rd-party materials may

result in diminished case performance.

Fig. 4 Cornice joints

CORNICE

ALIGNMENT

PIN

CORNICE

JOINT

4

Summary of Contents for 3NDML-NRG

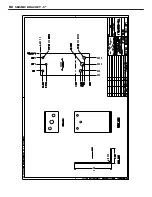

Page 16: ...BLUE WHITE BLACK 3NDML WIRING DIAGRAM B2 ...

Page 19: ...SEISMIC BRACKET 5 D2 ...

Page 20: ...SEISMIC BRACKET 7 D3 ...

Page 21: ...SEISMIC BRACKET 11 D4 ...

Page 22: ...SEISMIC BRACKET 15 D5 ...