11

CASE INSTALLATION

FLOOR PREP

1. Con

fi

rm with the general contractor that you have the

most current building dimensions, then ask for the

points of reference from which you should take dimensions to

locate the cases.

2. Using chalk lines or a laser transit, mark the

fl

oor

where the cases are to be located for the entire lineup.

The lines should coincide with the outside edges of the

case feet.

3. Leveling is necessary to ensure proper case alignment

and to avoid potential case damage. Locate the highest

point on the positioning lines as a reference for

determining the proper height of the shim-pack levelers.

A laser transit is recommended for precision and

requires just one person.

4. Locate the basehorse positions along the chalk lines,

then spot properly leveled shim packs at each location.

LINE-UP & INSTALLATION

Single Case

1. Roll the case into position, leaving a minimum of 2” between

the wall and back of case. This space must be unobstructed and

is required in order to leave suf

fi

cient room for air

fl

ow behind the

case.

2. Using a “J” bar, raise the end of the case (under cross

support), remove the caster assembly (Fig. 1) and lower

the basehorse on to the shim packs. Repeat on the

other end of the case.

3. Once the basehorse is properly placed on the shim

packs, check the vertical plumb of the case by placing

a bubble level on the shelf standard. Add/remove shim

packs as needed. For the horizontal level, repeat this

process after placing the bubble level on the front sill.

Multi-Case

1. Remove any shelves, shipping braces, mirror assemblies,

etc. Shelf clips and shipping braces can be discarded.

Keep all other loose items such as kick plates, end kick plates,

nose bumper, fascia, etc. for later in the installation process.

2. Remove the return air grill at the case joint. The grill

lifts out without fasteners and may be easily removed

to gain clear access to the case-to-case joining bolts.

3. Follow the single-case installation instructions for the

fi

rst case, then position the next case in the line-up approximate-

ly 3’ away. Remove the casters on the end that is closest to the

fi

rst case.

4. Apply the foam tape gasket (supplied) and two beads

of butyl or silicone sealant to the end of the

fi

rst case

(Fig. 1). From the opposite end, push the second case

to a position that is approximately 6” from the

fi

rst case,

then remove the remaining casters and position case

on the shim packs.

5. Push the cases tightly together, then lightly bolt them

together through the holes that are provided (Fig. 1).

Tighten all the joining bolts until all margins are equal.

Be careful not to over tighten.

6. Repeat steps 3–6 of this sequence for all remaining

cases. Be certain to properly level all cases.

7. See Appendix B for seismic bracket installation instruc-

tions.

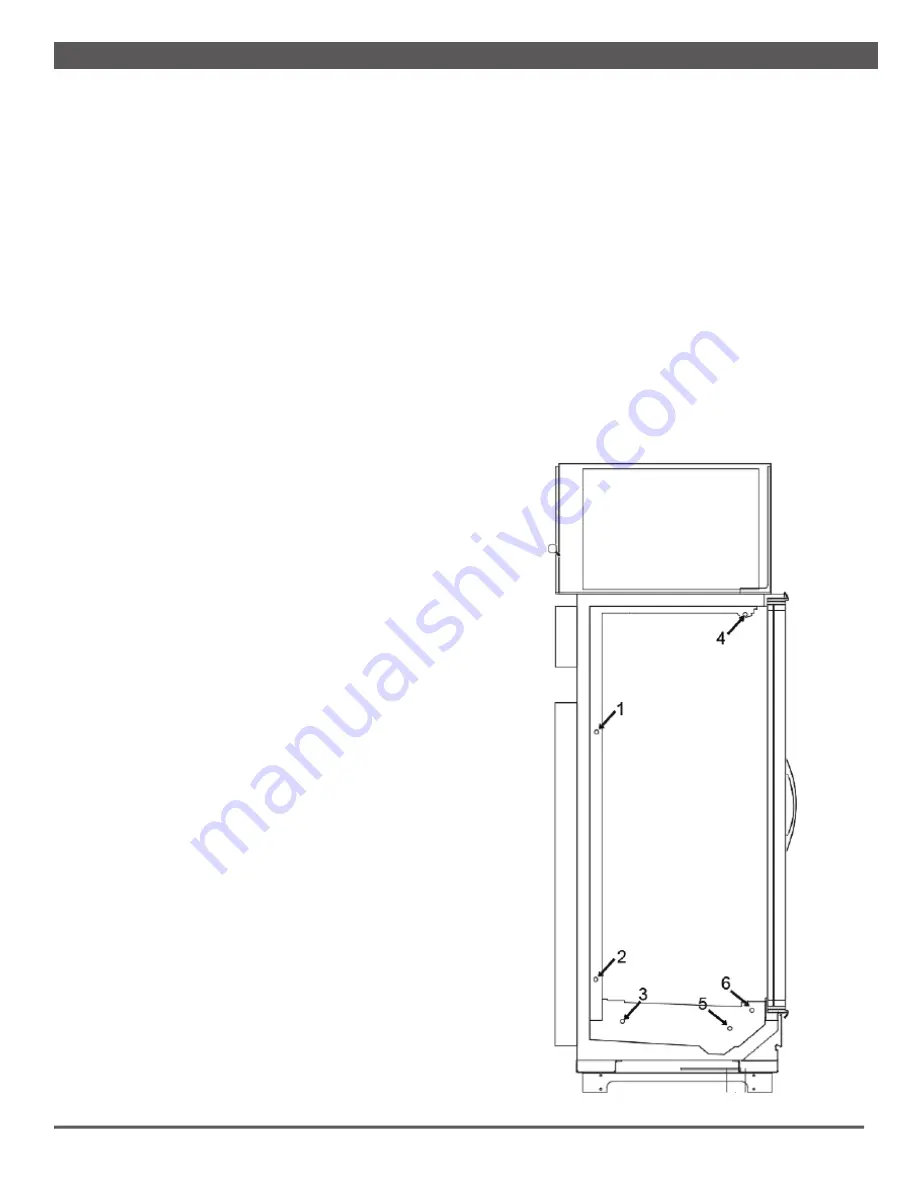

Fig. 1 Bolt holes, foam tape gasket and sealant

Summary of Contents for JNRBHSA

Page 2: ...ii ...

Page 33: ...B2 SEISMIC BRACKETS 5 BRACKETS ...

Page 34: ...C1 SPORLAN PRESSURE TEMPERATURE CHART ...

Page 38: ...Display Cases 5XIILQ 0LOO 5RDG RORQLDO HLJKWV 9 E3 ELECTRICAL WIRING DIAGRAM ...

Page 39: ...Display Cases 5XIILQ 0LOO 5RDG RORQLDO HLJKWV 9 E4 ELECTRICAL WIRING DIAGRAM ...

Page 46: ...G1 FASCIA FRAME ...

Page 47: ...G2 FASCIA FRAME ...

Page 48: ...G3 FASCIA FRAME ...

Page 49: ...G4 FASCIA FRAME ...

Page 50: ...G5 FASCIA FRAME OPTIONAL MOTION SENSOR INSTALLATION ...

Page 51: ...G6 FASCIA FRAME OPTIONAL MOTION SENSOR INSTALLATION ...

Page 53: ...G8 FASCIA FRAME JNRZHSA 5 BALLOON GUARD INSTALLATION ...

Page 55: ...I1 CASE LIFTING LOCATIONS Base Frame Lifting Locations for Forklift JNRBHSA JNRZHSA ...

Page 56: ...I2 CASE LIFTING LOCATIONS Base Frame Lifting Locations for Forklift JNRBHSA JNRZHSA ...

Page 57: ...v Ϯ Z Ͳ ϱ Z EZ v Ϯ Z Ͳ ϰ Z EZ v ϱ EZ J1 CONDENSING UNIT LOCATIONS ...