3

Step 1

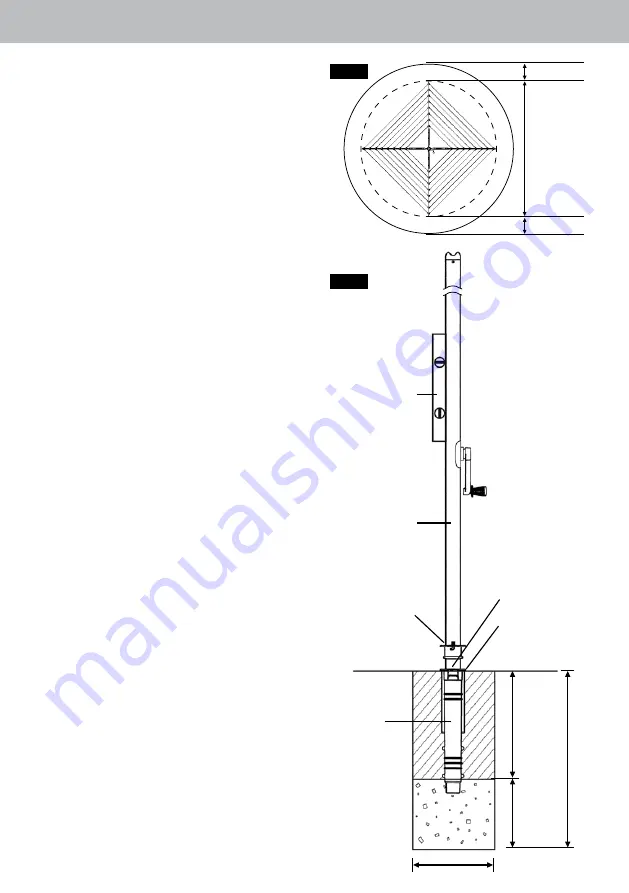

Select a Suitable Location

1.1

Select a suitable area for installation.

1.2

Allow a minimum of 500mm (1'7")

clearance around your Rotary Hoist (

Fig. 1

).

Step 2

Install the Ground Socket

2.1

Dig a hole 250mm (10") diameter by

approximately 650mm (26") deep (

Fig. 2

).

2.2

Place approximately 200mm (8")

of coarse gravel into the hole.

2.3

Insert the main standard into the ground

socket. Engage the locking collar and

lock into position.

Make sure

the tabs are closed to prevent

concrete entering the locking recess.

2.4

Place the ground socket and main

standard into the hole.

Push the base of the ground socket into

the gravel.

Check level vertically.

The top of the ground socket must sit

approximately 6-12mm (1/4"-1/2")

above ground level.

2.5

Support the main standard and

concrete into position.

Concrete should be damp enough

to ‘hold together’ when squeezed

in your hand.

Settle concrete by pushing a thin stick

into the mix several times.

Leave the main standard in the

ground socket until the concrete

has set.

Keep concrete out of the locking

recess in the ground socket.

2.6

Allow 24 hours for the concrete to set

before final assembly and use of your

Rotary Hoist.

Check for level

Main standard

Locking collar

Engage into

ground socket.

Rotate to lock.

Close tabs to

prevent entry

of concrete

Ground

socket

450mm

(18")

concr

ete

200mm

(8")

gravel

650mm

(26")

Fig. 1

Fig. 2

Installation

Top of socket

approximately

6-12mm (1/4"-1/2")

above ground level

250mm (10")

500mm (1'7")

500mm (1'7")

3.2m (10'6")

Rotary 37

3.6m (11' 9")

Rotary 47