4

Assembly

Arm and Stay Assembly

1.

Fit top cap lower assembly

792

to secondary

standard assembly

795

and fasten securely

with screw

204

and nut

409

(

Fig. 5

).

2.

Locate arm stay bracket

787

onto the arm

793

and align the mount holes.

Ensure the bracket is assembled as per

Fig 6

(with staples up).

3.

Squeeze the arm stay bracket

787

together

and fasten securely with screws

181

and nuts

434

(

Fig. 6

).

4.

Fit tube stays

794

to arm stay brackets

787

and fasten securely with screws

201

and

nuts

447

(

Fig. 6

).

5.

Place the arms into the cross and assemble

the tube stay into the top cap assembly

791

and

792

with the screw

203

.

Note:

Do not fit the nut yet.

6.

Repeat step 5 for the other three arms.

For Model 4 fit nuts

409

to screws

203

now.

For Model 5 refer to step 7.

7.

For Model 5, hook the inner rod stays

789

into the innermost staples on the arms.

Position other end underneath the top cap

lower assembly

792

and onto screw

203

.

Fit nuts

409

and tighten.

8.

Fit end caps

752

to the end of each arm.

Secondary Standard Assembly

1.

Remove the wind brake and plastic ring

ring from the top of the Main Standard

assembly by loosening the securing screw.

2.

Insert secondary standard

795

into top of

main standard.

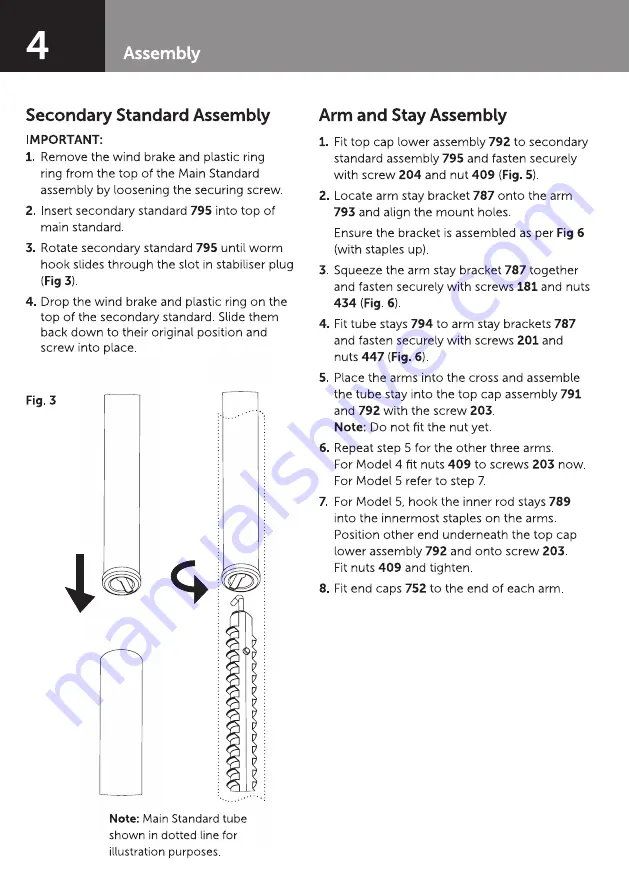

3.

Rotate secondary standard

795

until worm

hook slides through the slot in stabiliser plug

(

Fig 3

).

4.

Drop the wind brake and plastic ring on the

top of the secondary standard. Slide them

back down to their original position and

screw into place.

Fig. 3

Note:

Main Standard tube

shown in dotted line for

illustration purposes.

IMPORTANT: