13

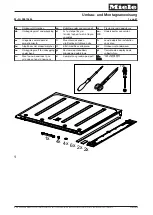

Item 12: Replacing the Windbrake and Winding Mechanism

1. Remove the hoist from the Ground Socket and lay it on the ground.

2. Remove the Handle Assembly as per Item 6.

3. Remove the screw in the Main Standard located behind the Handle Assembly. This screw

secures the Winding Mechanism within the Main Standard (Fig. 45).

4. Using a screwdriver and hammer, remove the Windbrake from the top of the Main

Standard (Fig. 46).

5. Carefully slide the Main Standard completely off the Secondary Standard, ensure that the

Winding Mechanism does not become dirty, and the Ground Socket Locking Collar does

not fall off. If the saddle or pinion gear become dislodged, clean and lubricate them with

Vaseline before replacing (Fig. 48).

6. Use a hacksaw to cut the bard off the top of the Worm (Fig. 47).

7. Fit a new Winding Mechanism into the Main Standard and secure with the screw (Fig. 49).

8. Push a new or the removed Windbrake into the top of the Main Standard, ensuring that

the moulding is aligned with the punched details in tube. Centre punch the tube in the

nibbed areas to re-secure (Fig. 50).

9. Slide the Main Standard over the Secondary Standard then stand hoist upright in the

Ground Socket to re-engage the worm with the Secondary Standard.

10. Re-attach the handle assembly as per Item 6.

Fig. 45

Fig. 46

Fig. 47

Fig. 48

Fig. 49

Fig. 50

Summary of Contents for Rotary 400

Page 2: ......

Page 7: ...7 Fig 11 Fig 12 Fig 13 Fig 14 Fig 15 Fig 16 Fig 17 ...

Page 15: ...15 Notes Issue November 2007 ...

Page 16: ......