12

Step 8 – Adjusting the width of your Supa Fold

Your Supa

Fold width can be reduced to suit your specific installation needs or to align

with existing stud centres.

The standard mount hole centres for your Supa

Fold model are shown in the table

on page 6.

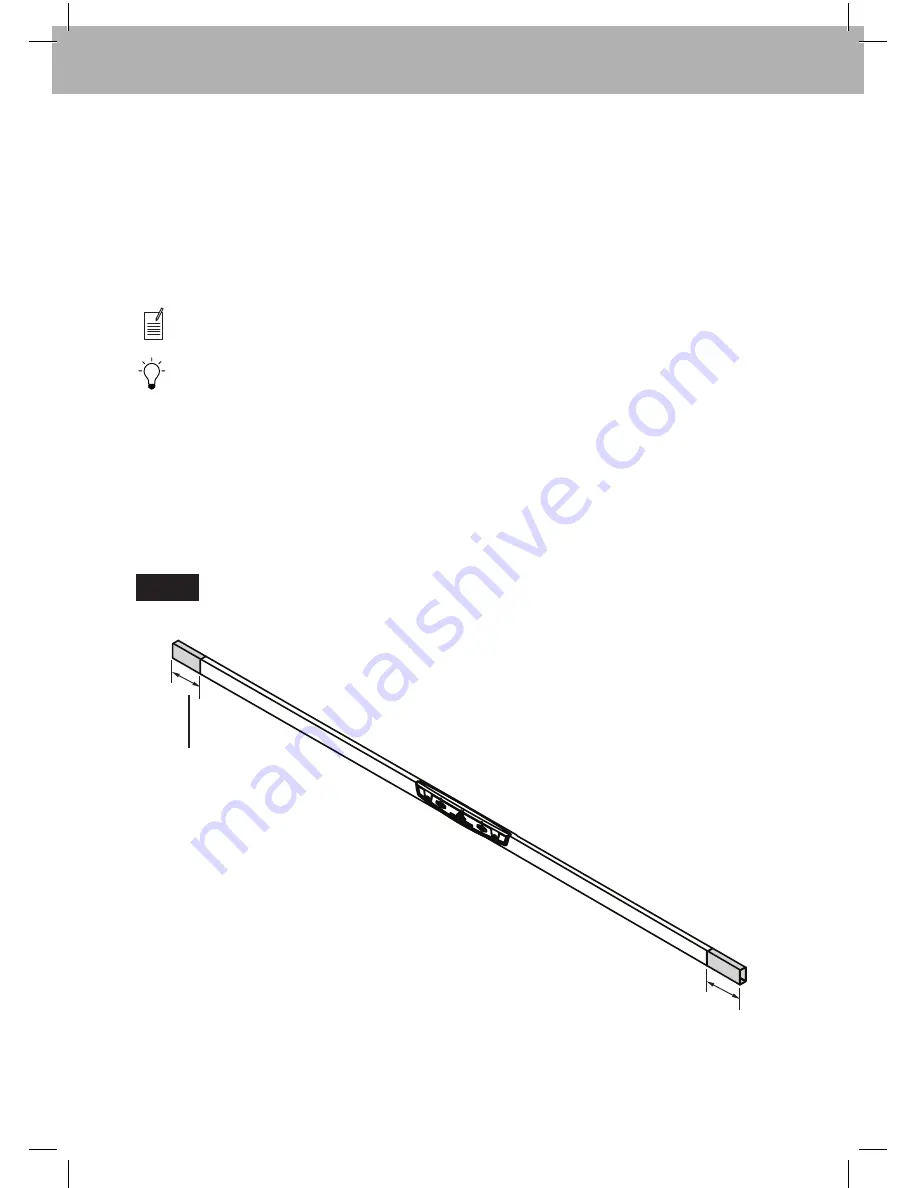

Determine the length you need to reduce your product, halve this amount and cut equal

lengths from the ends of the assembled spreader with a hacksaw (

Fig. 14

).

For the Supa

Fold Duo model, you will need to cut both the inner and outer

assembled spreader bars

• Cutting equal amounts from each end of the spreader will maintain the spreader

handle in the centre of the product.

• Be careful when cutting with a hacksaw, ensure you do not slip/damage the

powdercoat and keep the cut edge square. You may need to clean up the

edges with a file after cutting.

• Make sure the inside of the cut edges are smooth to allow the corners to slide

in easily.

Fig. 14

Cut equal lengths

from each end

Assembly

Summary of Contents for Supa Fold Duo

Page 22: ...22 Notes ...

Page 23: ...23 Notes ...

Page 24: ...Hills Holdings Limited A B N 35 007 573 417 Issue March 2011 PD2991c ...