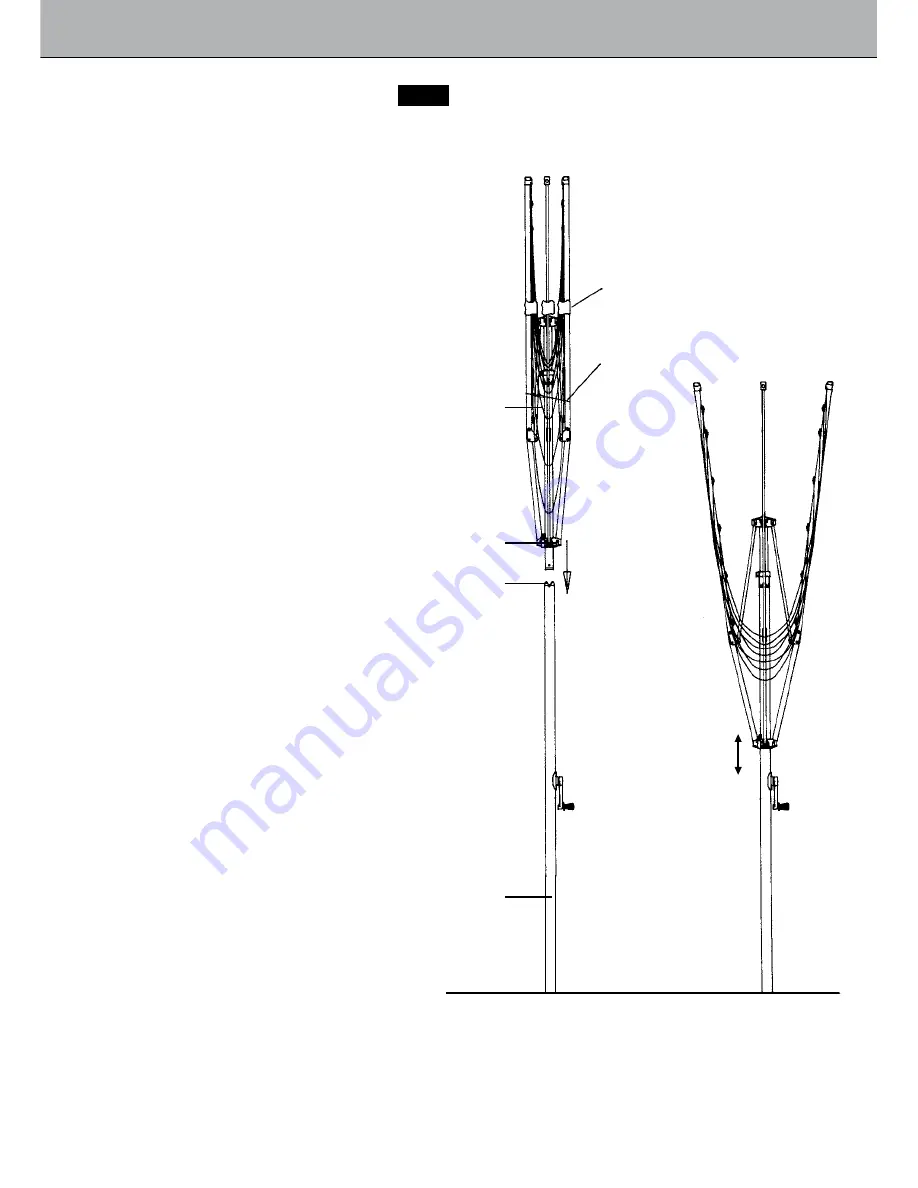

Assemble the Hoist

1.

Remove any packaging from the

head assembly.

2.

Place the main standard in the

ground socket.

3.

Place the bottom of the head

assembly into the top of the

main standard and lower it

gently until it stops (

Fig. 3

).

4.

To engage, raise the head

assembly by approximately

100mm (4”) and lower until

a ‘click’ is heard.

5.

Check the head assembly is

locked in position by lifting

upwards (it should not move).

If the head assembly is not

engaged, repeat Step 4.

Note:

there is a small amount

of rotational movement between

the wind brake and the lower

cross latch. This is normal.

Fig. 3

Ground level

4

Assembly

Main standard

Head assembly

Insert

head

assembly

Remove any

packaging

Tie-off cord

Lower cross

Wind brake

Engage by raising

and lowering until

a ‘click’ is heard