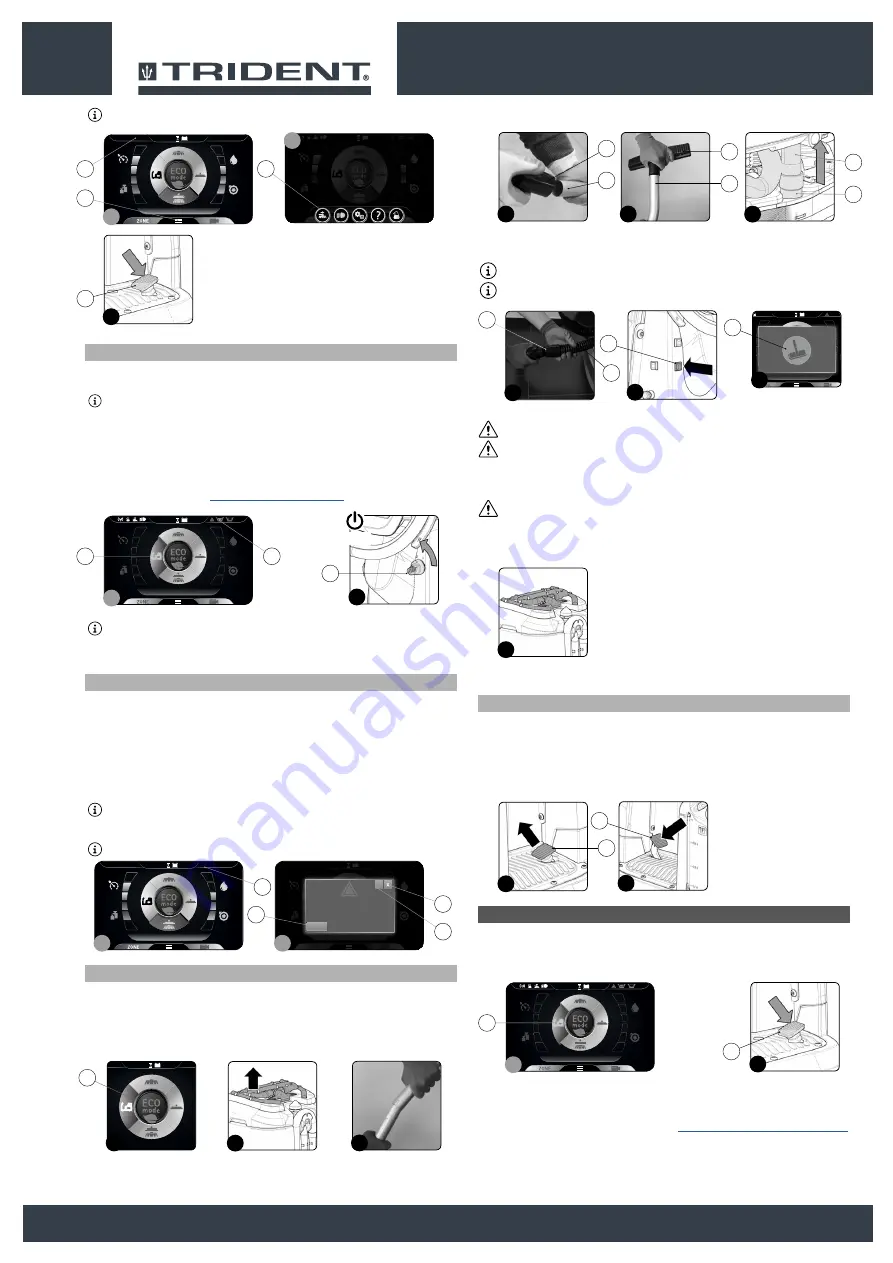

OVERFLOW DEVICE

The machine is equipped with an electro-mechanical device (float), located in the back of the recovery

tank, which deactivates the vacuum motor's control circuit when the recovery tank is full.

N.B.

: The electro-mechanical float only deactivates the electrical circuit when they mechanical

device (float) is engaged for at least four seconds. When the electric circuit remains open, the

symbol (1), regarding the critical level of the solution in the recovery tank,is displayed on the

working screen (

Fig.1

).

If this is the case, proceed as follows:

1. From the DS control panel select the TRANSFER mode (A) (

Fig.2

).

2. Bring the machine to the designated place for emptying the recovery tank.

3.

Switch off he machine and turn the key of the main switch to “0” (

Fig.3

).

4. Empty the recovery tank (see “

N.B.

: The machine will only start functioning correctly again after the next start-up.

2

2

OFF

DRIVE

0000.00

100%

1

A

1

N.B.

: to return to the working screen press on any point of the screen, except the edges of the

display or else wait three seconds without touching anything.

3

3

OFFICE

0000.00

100%

0000.00

100%

ECO mode

1

2

2

1

3

ALARM SCREEN

When an error occurs the symbol (1) is displayed in the information field (

Fig.1

), it remains visible until

the error is resolved.

The “ERROR” window will also be displayed in superimposition (

Fig.2

), in it are described the number

of the alarm, the group it belongs to and a brief description.

When an error occurs, do as follows:

1. Stop the machine and press the button (2) (

Fig.2

).

2.

If the error persists, switch off the machine, wait for at least ten seconds and switch on the machine.

N.B.

: to close the error screen press the button (3) (

Fig.2

).

3. If the error persists contact the nearest service centre.

N.B.

: the symbol (1) (

Fig.1

) remains visible until the error is resolved.

OFFICE

0000.00

100%

ECO mode

0000.00

100%

Italiano

English

Spanish

French

German

Allarme 1

Gruppo

Descrizione

Reset

?

1

2

1

2

3

4

VACUUM WAND KIT (OPTIONAL)

Upon request, the machine can be fitted with the VACUUM WAND system that vacuums up the

detergent solution more accurately.

To start it do as follows.

1. Using the DS selector on the control display (

Fig.1

), select the “transfer” program” (1).

2. Remove all the vacuum kit components from the storage compartment (

Fig.2

).

3. Assemble the steel extension tube (

Fig.3

).

4. Connect the vacuum tube (4) to the extension tube (3) (

Fig.4

).

2

3

Back

0000.00

100%

1

1

5. Insert the vacuum brush (5) in the extension tube (3) (

Fig.5

).

6. Remove the vacuum tube (6) from the sleeve (7) in the squeegee body (

Fig.6

).

7. Connect the wand kit vacuum tube (4) to the squeegee vacuum tube (5) (

Fig.7

).

8. Activate the vacuum control kit by pressing the button (8) (

Fig.8

).

N.B.

: as soon as the button (8) is pressed, the LED on it will light up (

Fig.8

).

N.B.

: as soon as the button (8) on the control display is pressed, the symbol (9) will appear

(

Fig.9

).

WARNING

: never pick up solid matter such as dust, cigarette stubs, paper, etc.

CAUTION

: never collect gases, explosive/inflammable liquids or powders, nor acids and

solvents! These include gasoline, paint thinners and fuel oil (which, when mixed with the

vacuum air, can form explosive vapours or mixtures), and also non-diluted acids and solvents,

acetones, aluminium and magnesium powders. These substances may also corrode the

materials used to construct the machine.

CAUTION

: if the machine is used in dangerous areas (e.g. petrol stations), the relative safety

standards must be observed. It is forbidden to use the machine in environments with a

potentially explosive atmosphere.

12.

Once the work is finished, remove the kit and place it back in the support that can be found on

the upper part of the recovery tank cover (

Fig.10

).

4

4

3

6

5

5

6

3

7

7

4

5

8

8

0000.00

100%

9

9

10

BRAKING CONTROL

The machine has an encoder to help braking and also a mechanical brake.

•

If the machine is moving and the accelerator pedal (1) (

Fig.1

) is released, la the machine brakes

decelerating softly, until it stops the encoder. Only when the encoder has stopped is the electric

brake engaged.

•

If the machine is moving and the brake pedal (2) (

Fig.2

) is pressed, the machine according to

braking force of the mechanical system. Only when the encoder has stopped is the electric brake

engaged.

1

1

2

2

AT THE END OF THE WORK

At the end of the work, and before carrying out any type of maintenance, perform the following

operations:

1. From the DS control panel select the TRANSFER mode (A) (

Fig.1

).

2. Press the drive pedal (1) (

Fig.2

) to begin moving the machine.

3. Take the appliance to the dedicated dirty water drainage area.

4.

Switch off the machine turning the key (2) of the main switch a quarter turn anti-clockwise (

Fig.3

).

Remove the key from the instrument panel.

5. Carry out all the procedures listed in the paragraph “

RECOMMENDED PERIODIC MAINTENANCE

indicated in the column “AT THE END OF THE WORK”.

6. Sit on the driver’s seat.

2

1

DRIVE

0000.00

100%

1

A

26