7. Insert the key (2) into the main switch on the control panel. Set the main switch to "I" (

Fig.4

).

8. Press the drive pedal (1) (

Fig.1

) to begin moving the machine.

9. Take the appliance to the designated machine storage place.

ATTENTION

: Park the machine in an enclosed place, on a flat surface, and at a safe distance

from any objects that could either damage it or be damaged due to contact with the machine

itself.

10. Secure the machine, see the section titled “

3

4

2

2

ON

OFF

RECOMMENDED MAINTENANCE OPERATIONS

DRAINING THE RECOVERY TANK

Proceed as follows to empty the recovery tank:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

CAUTION

: users are advised to always wear protective gloves, to avoid the risk of serious injury

to hands.

3. Remove the drainage hose of the recovery tank from the clamps; it is located at the rear of the

machine (

Fig.1

).

4. Bend the end of the drainage tube in order to create a choke and prevent the content from coming

out (

Fig.2

), then position the tube on the discharge surface, unscrew the cap, and gradually release

the tube.

N.B.

: the place designated for this operation must comply with current environmental protection

regulations.

5. Repeat the operations in reverse order to reassemble all the parts.

2

1

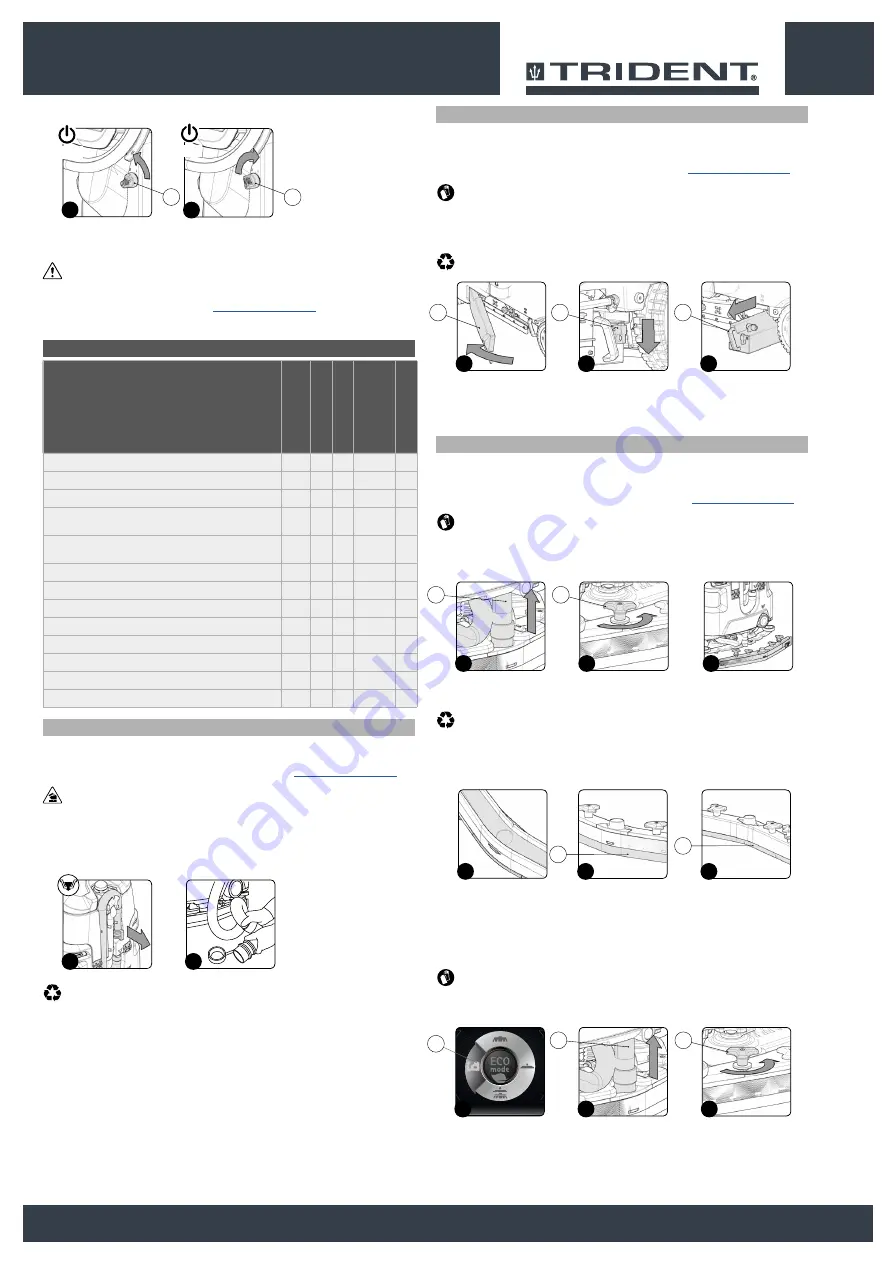

EMPTYING THE DEBRIS HOPPER (SWEEPING VERSION)

The thorough cleaning of the debris hopper ensures better floor cleaning performance. To empty the

debris hopper, proceed as follows:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

”).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

3. Open the machine's left lateral carter (1) (

Fig.1

).

4. Release the debris hopper locking pin (2) (

Fig.2

).

5. Use the handle (3) to extract the debris hopper (

Fig.3

) and empty it.

N.B.

: the place designated for this operation must comply with current environmental protection

regulations.

6. Clean the inside with a jet of water, and use a brush to remove any residual impurities if necessary.

7. Proceed in the opposite order to reassemble all the parts.

2

3

1

2

1

3

CLEANING THE SQUEEGEE BODY

The careful cleaning of the whole vacuum unit ensures better drying and cleaning of the floor as well

as a longer vacuum motor life. To carry out the cleaning of the squeegee body, proceed as follows:

1. Take the machine to the maintenance area.

2. Make sure the machine has been secured (see the section titled “

”).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

3. Extract the vacuum hose (1) from the vacuum nozzle on the squeegee body (

Fig.1

).

4. Completely unscrew the knobs (2) in the squeegee body's pre-assembly (

Fig.2

).

5. Remove the squeegee body from the slits in the squeegee connector (

Fig.3

).

6. Thoroughly clean the squeegee body vacuum chamber (4) with a jet of water, and then with a

damp cloth (

Fig.4

).

N.B.

: the place designated for this operation must comply with current environmental protection

regulations.

7. Thoroughly clean the squeegee body's rear rubber blade (5) with a jet of water, and then with a

damp cloth (

Fig.5

).

8. Thoroughly clean the squeegee body front rubber blade (6) with a jet of water, and then with a

damp cloth (

Fig.6

).

9. Thoroughly clean the vacuum nozzle with a jet of water, and then with a damp cloth.

10. Proceed in the opposite order to reassemble all the parts.

To clean the squeegee body with the optional spray gun kit, proceed as follows:

1. Take the machine to the maintenance area.

2. Using the DS selector on the control display (

Fig.1

), select the “transfer” program” (1).

CAUTION

: these operations must be carried out using protective gloves to avoid any possible

contact with the edges or tips of metal objects.

3. Extract the vacuum hose (2) from the vacuum nozzle on the squeegee body (

Fig.2

).

4. Completely unscrew the knobs (3) in the squeegee body's pre-assembly (

Fig.3

).

2

3

1

1

2

6

4

5

3

4

DRIVE

0000.00

100%

1

1

3

2

2

3

27

TYPE OF MAINTENANCE

AT THE END OF THE WORK

DAIL

Y

WEEKL

Y

BEFORE A

LONG

PERIOD OF NON- USE

TRANSPORT

DRAINING THE RECOVERY TANK

X

X

X

EMPTYING THE DEBRIS HOPPER (SWEEPING VERSION)

X

CLEANING THE SQUEEGEE BODY

X

X

X

CLEANING THE BRUSH HEAD BRUSHES (SCRUBBING

VERSION)

X

X

CLEANING THE BRUSH HEAD BRUSHES (SWEEPING

VERSION)

X

X

CLEANING THE LATERAL BRUSH (SCRUBBING VERSION)

X

X

CLEANING THE LATERAL BRUSH (SWEEPING VERSION)

X

X

CLEANING THE RECOVERY TANK FILTERS

X

X

CLEANING THE RECOVERY TANK

X

X

EMPTYING THE SOLUTION TANK

X

X

X

CLEANING THE WATER SYSTEM FILTER

X

X

CLEANING THE DEBRIS HOPPER

X

X

CLEANING THE VACUUM TUBE

X

X