4.2.5

Brush Motor - Orbital

• Put the machine in safe conditions.

• Disassemble the complete Brush

Deck

(see section

at page

.

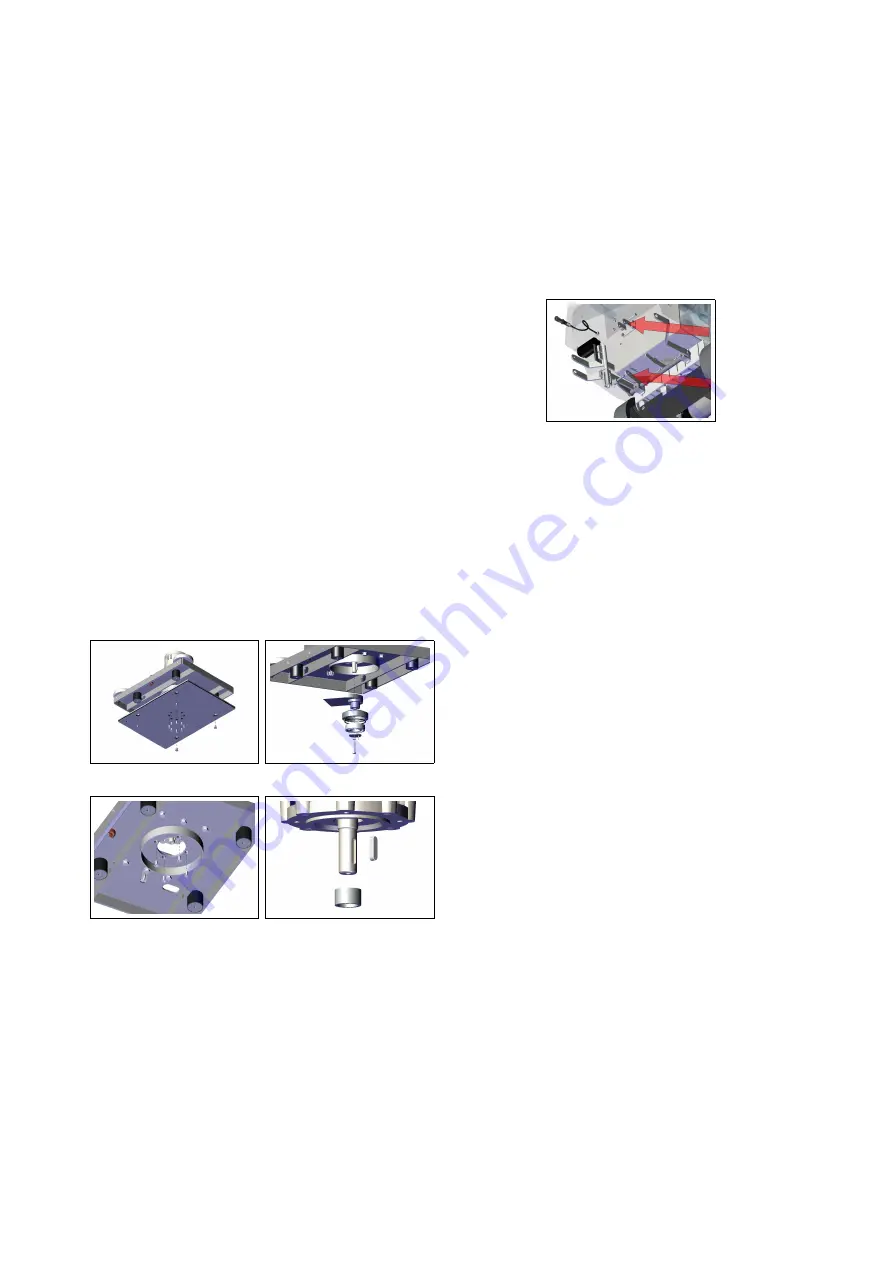

• Remove the Pad from the brush

deck.

• Remove the Pad Holder by unscrew-

ing the fixing screws

(see fig.

.

• Unscrew the central screw from the

motor shaft and remove the washer

with plug, the bearing and its sup-

port, and the orbital flange

(see fig.

.

• Remove the screws and the Motor

(see

fig.

.

• Remove the shaft key and the spacer

(see fig.

.

4.2.5-20

4.2.5-21

4.2.5-22

4.2.5-23

4.2.6

Brush deck Actuator

• Put the machine in safe conditions.

• Disassemble the complete Brush

Deck from the machine

(see section

at page

,

(see section

at page

.

• Release the plug and disconnect the

actuator arm from the brush deck

arm.

• Remove the elastic ring, and remove

the actuator from its support

(see fig.

.

4.2.6-24

4.3

Drying System

4.3.1

Squeegee Support

• Put the machine in safe conditions.

• Disassemble the Squeegee from the

Machine.

• Be sure that the Squeegee Com-

mand Lever is in lower position.

• Unscrew the screw that fix the chain

to the Squeegee Command Lever and

let it lie behind the Squeegee Sup-

port.

• Loose the nuts that block the Gas

Spring to the Squeegee Support and

Remove the Gas Spring.

• Loose the screws that block the

Squeegee Support to the Squeegee

Rotation Arm.

• Remove the Squeegee Support.

• Proceed at reverse to refit the part,

paying attention to take care about

the bushing positioning.

23

Summary of Contents for TRIDENT T20SC PRO

Page 1: ...SERVICE MANUAL TRIDENT T20SC PRO Version AB Date November 7 2018 Document Number 10077483...

Page 4: ...Part I Product Introduction 4...

Page 8: ...Part II Anomalies Resolution Guide 8...

Page 28: ...Part III Machine Description 28...