10

Spare parts specific

Pos. Description

Qty

HTJ-6D

HTJ-10D

HTJ-25D

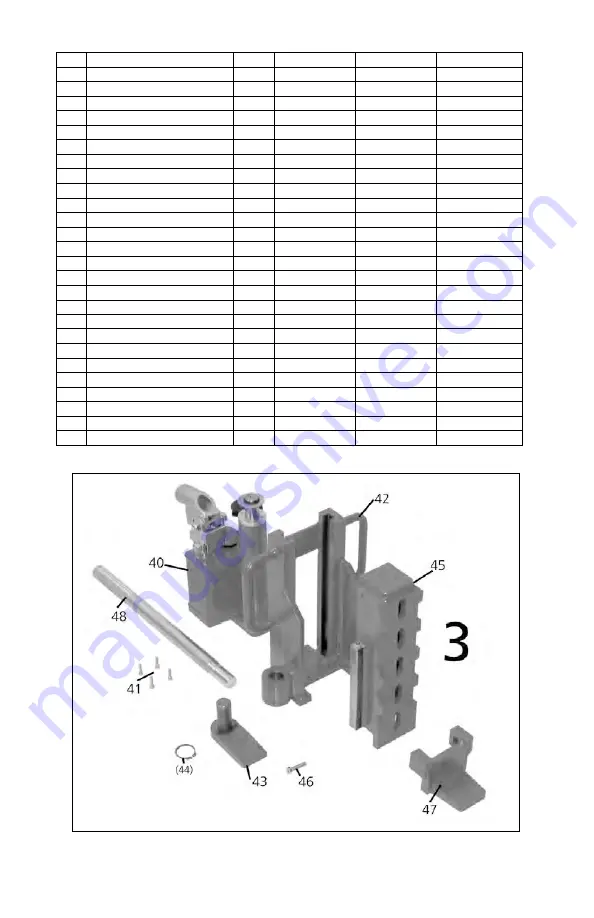

Diagram 3:

40 Pump /cylinder S/G-FLT 1

950620000

950620000

950620000

Cylinder XR

1

991103045

991103100

991103250

41 Screw cylinder S/G-FLT

4

990191019

990179007

990179007

Cylinder XR

1

990191022

990191023

990191025

42 Frame S/G-FLT

1

950610101

950610101

950610101

Frame XR

1

950610101

950610101

950610101

43 Swiveling leg

2

950610201

950610201

950610201

44 C-Clip/Nut+washer leg

2

990147007

990147007

990147007

45 Lifting unit S/G-FLT

1

950630000

950630000

950630000

Lifting unit XR

1

950630000

951130000

951130000

46 Screw lifing unit

1

990179008

990179006

990179001

47 Toe

1

950640000

951040000

952540000

48 Lever

1

991057400

991057400

991057400

Diagram 4:

50 Piston rod

1

950650300

951050300

952550300

51 Piston

1

950650200

951050200

952550200

52 Piston guide

1

991001050

991001100

991001250

53 U-Seal piston

1

991003050

991003100

991003250

54 C-Clip piston

1

990147002

990147005

990147010

55 Piston head

1

950650100

991050100

952550100

56 Piston head guide

1

991002050

991002100

57 C-Clip securing plate

1

990147006

990147002

Screw securing plate

1

990179005

58 Securing plate S/GFLT1 1

950550400

951050400

952550400

Summary of Contents for Deluxe Toe Jack

Page 8: ...8...