KNOWING ESSENTIAL FIELD TROUBLE SHOOTING

12

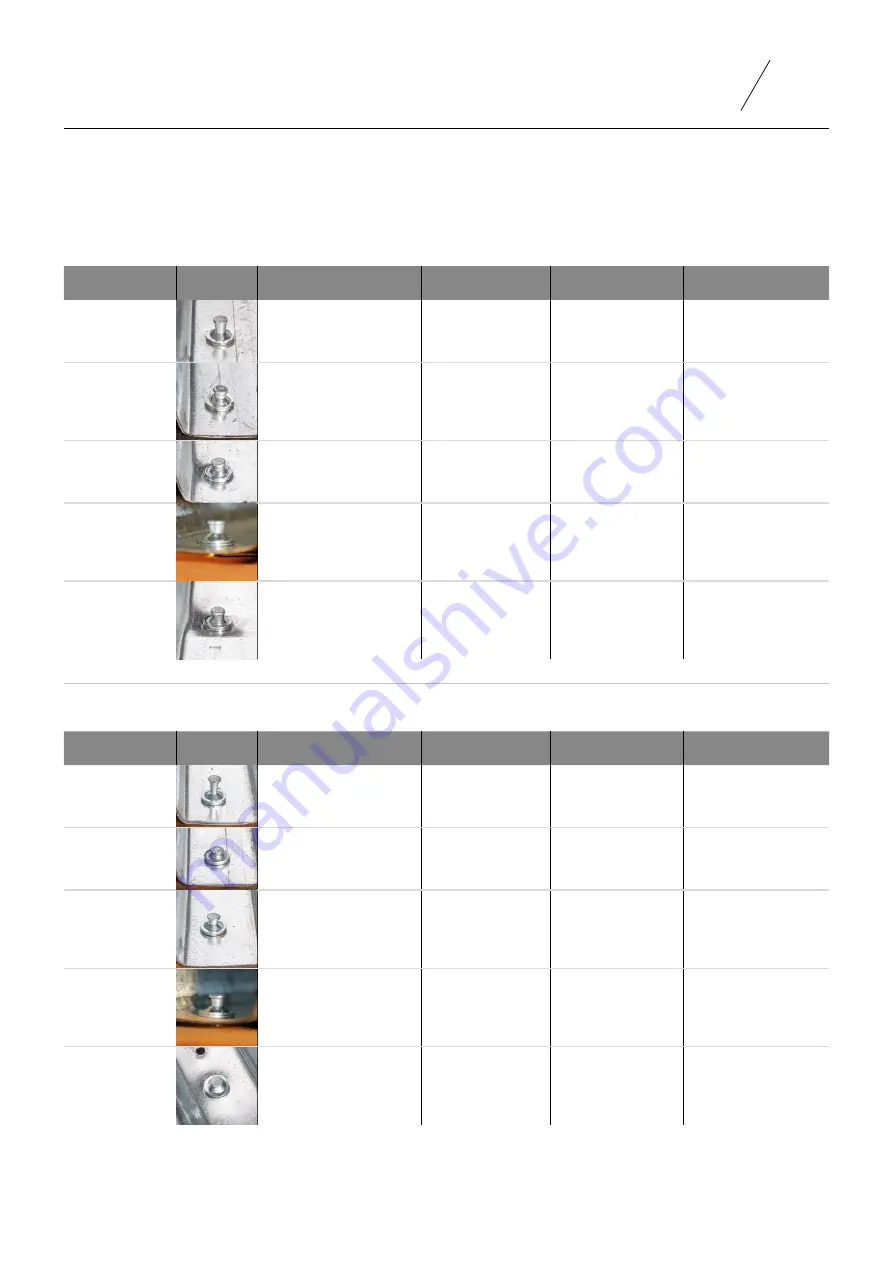

POSSIBLE CAUSES NAILS

Issue

Visual

Criteria

Trouble

Possible cause

Action

Nail stand-off

too high

No piston mark visible,

nail head stays off,

stand-off too high

Deck is not fas-

tened properly to

the beam

Power setting too

low or cartridge

not strong enough

Dial up power

setting or increase

strength of cartridge

Nail stand-off

is too low

Washer compressed,

piston mark clearly

visible

Deck is not fas-

tened properly to

the beam

Power setting too

high or cartridge

is too strong

Dial down power

setting or decrease

strength of cartridge

Nail stand-off

is OK

Washer compressed,

piston mark slightly

visible, deck flat – no

deformation

–

–

–

Gap between

deck profile

and beam

Nail stand off OK or

too low, deck slightly

deformed

Deck profile

does not lay solid

on the beam

Gap caused by

slope of the deck

or local effects

Avoid gap between

sheet and beam or

fasten at the right

side of the beam

Beam miss

Nail stand off OK or too

low, sheet metal one

sided deformed (edge

of the beam visible)

Beam miss

Deck not marked

Mark the deck

Issue

Visual

Criteria

Trouble

Possible cause

Action

Nail stand-off

too high

No piston mark visible,

nail head stays off,

stand-off too high

Deck is not fas-

tened properly to

the beam

Power setting too

low or cartridge

not strong enough

Dial up power

setting or increase

strength of cartridge

Nail stand-off

is OK

Washer compressed,

piston mark clearly

visible, deck flat – no

deformation

–

–

–

Nail stand-off

is too low

Washer over compres-

sed, deck deformed,

stand-off too low

Deck is not fas-

tened properly to

the beam

Power setting too

high or cartridge

is too strong

Dial down power

setting or decrease

strength of cartridge

Gap between

deck profile

and beam

Nail stand off OK or

too low without piston

clear mark

Deck profile

does not lay solid

on the beam

Gap caused by

slope of the deck

or local effects

Avoid gap between

sheet and beam or

fasten at the right

side of the beam

Beam miss

Nail stand off OK or too

low, sheet metal one

sided deformed (edge

of the beam visible)

Beam miss

Deck not marked

Mark the deck

X-ENP2K-20

X-ENP-19