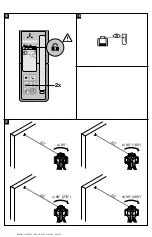

(locked) automatically. The enabled side can be changed

by double-clicking the lock symbol.

In order to avoid incorrect operation, the “Automatic

alignment”, “Surveillance” and “Special line” commands

must be confirmed by a double click. For the sake of

simplicity, this is not mentioned each time in further

sections of these operating instructions.

7.3 Basic functions of the PRI 36

The tool is designed to be used to determine, transfer

and check levels, verticals, slopes and right angles.

7.3.1 Setting the speed of rotation

2 4

NOTE

The speed of rotation can be adjusted by pressing the

“Speed of rotation” button (on the control panel of the

rotating laser or on the PRA 36). The speeds of rotation

are 300, 450 and 600 /min.

7.3.2 Selecting the line function

2 4

NOTE

When the “Line” button is pressed, the rotating laser

projects a line which can be lengthened or shortened by

further presses of the button.

NOTE

With the aid of the PRA 36 laser receiver it is also possible

to stop rotation of the laser and to project a line at the

position of the PRA 36. To do this, move the PRA 36 laser

receiver into the plane of the laser beam and press the

“Special line” button twice (double click).

7.3.3 Moving the laser line

The laser line can be moved to the left or right by pressing

the “Direction” buttons (PRI 36 or PRA 36). Holding down

the button results in continuous movement and increases

the speed of movement of the laser line.

7.4 Working in the horizontal plane

3 4

1. Depending on the application, the rotating laser

may, for example, be mounted on a tripod or, alter-

natively, on a wall mount. The angle of inclination of

the surface on which it stands should not exceed ±

5°.

2. Press the on / off button.

3. The laser beam switches on and the head begins to

rotate at a speed of 300 /min as soon as the tool

has leveled itself.

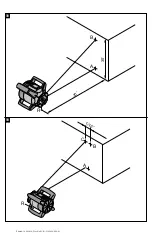

7.5 Working in the vertical plane

14

1. When working in the vertical plane, place the tool

on its metal feet so that the control panel faces

upwards. Alternatively, the rotating laser may also be

mounted on a suitable tripod, wall bracket, facade

adapter or batter board adapter.

2. Adjust the tool so that its vertical axis is positioned

in the required direction.

3. In order to ensure that the tool’s specified accuracy

can be maintained, make sure that it is set up on

a level surface or mounted sufficiently level on the

tripod or other accessory.

4. Press the on / off button.

After the tool has leveled itself automatically, it

projects a stationary laser beam vertically down-

wards. This projected point is the reference point

and is used to position the tool.

5. The speed of rotation can be adjusted by pressing

the “Speed of rotation” button (on the control panel

of the rotating laser or on the PRA 36).

7.5.1 Manual alignment

Manual alignment of the vertical plane is carried out by

pressing the direction buttons (up/down) on the rear of

the PRA 36.

7.5.2 Auto-alignment

15

Hold the PRA 36 at the point to be aligned, with the

receiving side facing the PRI 36, and then press the

“Automatic alignment” button twice in quick succession.

NOTE

Check to ensure that the receiving side of the receiver

is not disabled (locked). Double-click the lock symbol to

unlock the side of the receiver.

The laser plane alignment procedure then begins. Short

signal tones are emitted while this is taking place.

The direction of the search can be changed by pressing

the “Automatic alignment” button.

The alignment procedure can be canceled by a double

click.

As soon as the laser beam strikes the receiving window

of the PRA 36, the beam moves to the position of the

marking notch (reference plane).

A continuous signal tone is emitted, indicating the end

of the procedure, as soon as the laser beam finds the

position of the marking notch.

If the automatic alignment process was not successful

(takes more than 2 min.), short signals sound and the

automatic alignment symbol goes out. This indicates that

the automatic alignment process was aborted.

7.6 Working with slopes

NOTE

For optimum results, check that the PRI 36 is correctly

aligned. The best way to do this is by selecting 2 points

on the left and right of the tool, each at 5 m (16.4 ft), but

parallel to the tool axis. Mark the height of the horizontal

plane and then, after setting the slope, mark the heights.

The tool is aligned optimally only when these heights are

identical at both points.

en

11

Printed: 14.04.2014 | Doc-Nr: PUB / 5162040 / 000 / 01

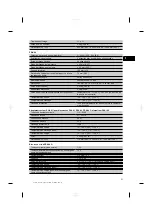

Summary of Contents for PRI 36

Page 2: ...1 Printed 14 04 2014 Doc Nr PUB 5162040 000 01...

Page 3: ...2 3 4 5 Printed 14 04 2014 Doc Nr PUB 5162040 000 01...

Page 4: ...6 7 8 9 10 11 Printed 14 04 2014 Doc Nr PUB 5162040 000 01...

Page 5: ...12 14 13 Printed 14 04 2014 Doc Nr PUB 5162040 000 01...

Page 6: ...35 15 D F E G 17 16 Printed 14 04 2014 Doc Nr PUB 5162040 000 01...

Page 7: ...18 5 19 5 Printed 14 04 2014 Doc Nr PUB 5162040 000 01...