10

en

2. Description

2.1 Use of the tool as directed

The ST 1800 is a hand-held, electric mains-powered tool

for driving screws used to fasten sheet metal in metal

construction applications.

It is used to drive or remove the recommended metal

construction screws in the applicable materials.

The working environment may be a construction site of

any kind where metal construction work is taking place.

Use of a screw magazine is possible and provision has

been made for this (SDT 25).

Only the specified screwdriving bits, magazine and acces-

sories may be used with the tool. The general safety pre-

cautions listed in the operating instructions must be

observed.

The tool is intended for professional use.

The tool may be operated, serviced and repaired only by

authorized, trained personnel. This personnel must be

informed of any special hazards that may be encoun-

tered.

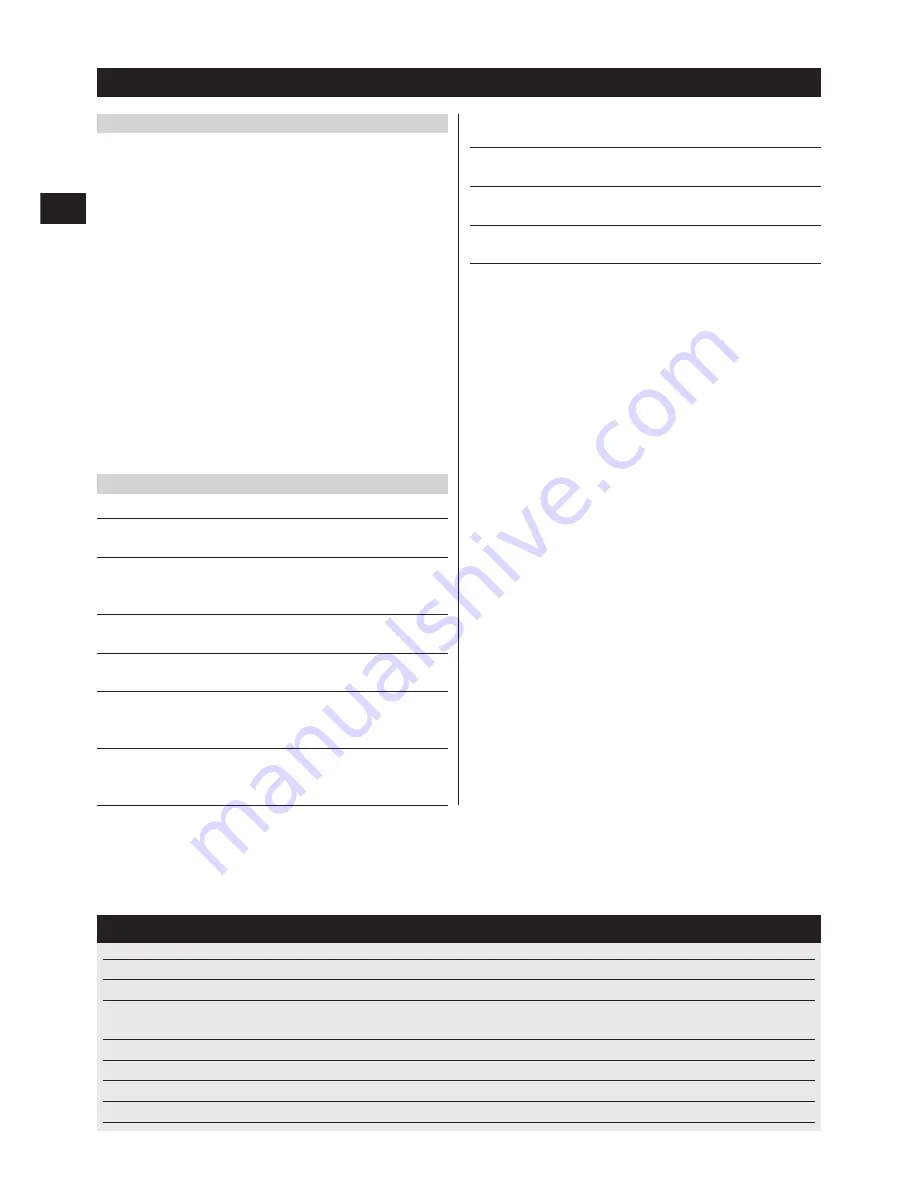

2.2 Main applications / torque settings

Application

Screw type / diameter in mm

Torque setting

Sheet metal on

S-MD / 4.2

1–2

sheet metal

S-MD / 4.8

1–8

Sheet metal on

S-MD 51 + S-MD 21 / 5.5

8–13

steel profile

S-MD 53 + S-MD 23 / 5.5

6–11

S-MP 52 / 6.3

4–12

Sheet metal on

S-MD 55 + S-MD 25 / 5.5

2–7

steel beam

S-MP 53 / 6.5

8–14

Sheet metal on

wood

S-MP 53 / 6.5

14 – max.

Fiber-cement

board on

steel profile

S-FD 03 / 6.3

6–12

Fiber-cement

board on

steel beam

S-FD 05 / 6.3

12–15

Fiber-cement

board on wood

S-FD 01 / 6.5

12 – max.

Sandwich panel

on steel profile

S-CD 63 / 5.5

2–7

Sandwich panel

on steel beam

S-CD 65 / 5.5

2–9

Sandwich panel

on wood

S-CDW 61 / 6.5

5–8

The above settings are intended as an approximate guide-

line. They result from evaluation of the characteristic

curves for the torque clutches of tools tested in quality

assurance tests and from torque values obtained from

the corresponding screw tests.

Chuck:

1

/

4

″

hexagon socket

Operating controls

Control switch with lockbutton

Forward / reverse pushbutton

Torque adjusting ring

Depth gauge adjusting ring

Items supplied as standard equipment

– ST 1800 electric screwdriver

– S-GT17 depth gauge (for screws with sealing

washers of up to 17 mm diameter)

– Operating instructions

– Toolbox or cardboard box (depending on version)

3. Accessories and insert tools

Scaffold hook

Belt hook

Depth gauge

S-GT 23 for screws with sealing washers of up to

23 mm in diameter

Depth gauge

S-GU13 for bit holder and bit (PH, PZ, TX etc.)

Hex. sockets

Sockets for hex. screws (7, 8, 10, 12,

1

/

4

″

,

5

/

16

″

,

3

/

8

″

)

Decking tool

SDT25 for serial fastening applications

Bits and bit holders

TX, PH and TX bits; S-BH bit holder

Printed: 07.07.2013 | Doc-Nr: PUB / 5139844 / 000 / 00