5

●

Cable Requirements. A flame resistant portable cable

bearing a MSHA assigned identification number, ade-

quately protected by an automatic circuit-interrupting

device shall be used. Special care shall be taken in

handling the cable to guard against mechanical injury

and wear. Splices in portable cables shall be made in

a work man like manner, mechanically strong, and

well insulated. Only one temporary splice may be made

in any trailing cable. Such trailing cable may only be

used for the next 24-hour period. No temporary splice

shall be made in a trailing cable within 25 feet of the

machine, except cable reel equipment. Connections

and wiring to the out by end of the cable shall be in

accordance with recognized standards of safety.

DO NOT CHANGEWITHOUT APPROVAL OF MSHA

JKL Company Date: November 21, 2007 Drawing No.

1894

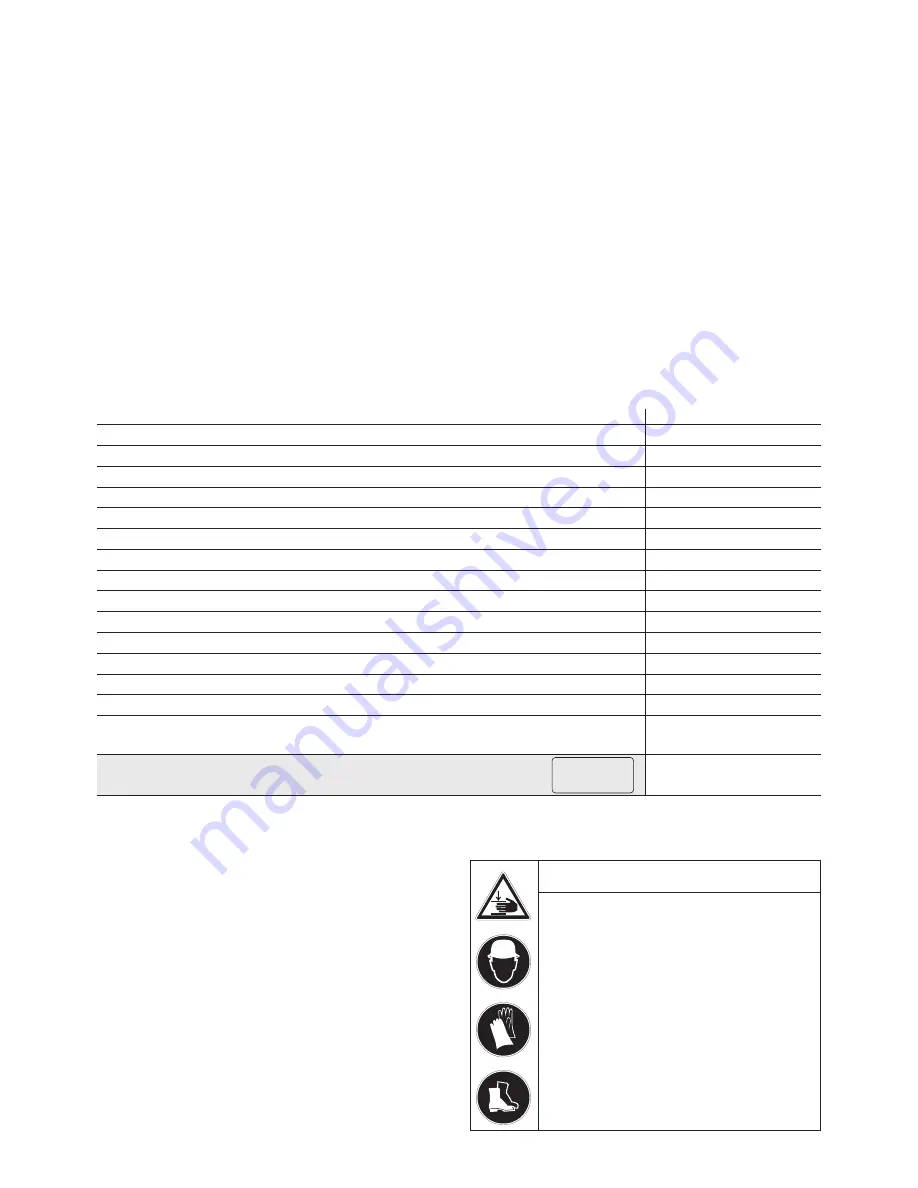

-CAUTION-

■

The tool, drill bit and drill support are

heavy.

■

There is a risk of pinching parts of the

body.

■

Wear a safety helmet, protective gloves

and safety footwear.

5. Assembly

It is essential that safety rules printed in these operating

instructions are read and observed.

-CAUTION-

The tool must be disconnected from the mains supply

while being set up and made ready for use.

5.1 Fitting the drill bit

Parts used: TE-MDR and TE-MDH

1. Push the drill bit head onto the front end of the drill

steel and tap it lightly until it holds securely.

4.2 Technical data

TE MD20 MSHA

TE MD20 GFCI

Rated voltage

220–240 V single phase

220–240 V single phase

Rated current

15 A

15 A

Power input

2200 W

2200 W

Mains frequency

50–60 Hz

50–60 Hz

Torque

100 Nm

100 Nm

Revolutions (counter-clockwise)

205 r.p.m.

205 r.p.m.

Impact energy

28 J

28 J

Dimensions

770

×

210

×

230

770

×

210

×

230

Drill bit head diameter

28–51 mm

28–51 mm

Drill steel length

up to 2,4 m

up to 2,4 m

Protection class I

Protection class I

Protection class I

Storage temperature without cooling water

–20°C to +55°C

–20°C to +55°C

Uncertainty (K)

1,5 m/s²

1,5 m/s²

Weight (tool without supply cord)

23,5 kg

23,5 kg

Protection against entry of water or foreign objects

Plug: IP 66, IP 67

GFCI: rain proof

Tool: IP 66

Tool: IP 66

Explosion

Permissible Electric Power Tool

No explosion

protection

Approval No. 18-A11009-0, Model No TE MD20

protection

Right of technical changes reserved.

4. Functional description

4.1 Description

The tool is a water-cooled, electrically-powered rotary

hammer drill with pneumatic hammering mechanism.

Handheld use is not allowed.

The tool is available in various versions:

TE MD20 GFCI (FFE: 408885)

TE MD20 MSHA (FFE: 424714)

The TE MD20 MSHA are suitable for use in areas where

there is a risk of explosion and in mining environments.

MSHA

U.S. Department of Labor

Mine Safety and Health Administration

Printed: 20.04.2017 | Doc-Nr: PUB / 5136192 / 000 / 00

Printed: 20.04.2017 | Doc-Nr: PUB / 5136192 / 000 / 01