System

Concept for HIQuad X

HI 803 211 E Rev. 1.01.00

Page 15 of 110

3.2.1

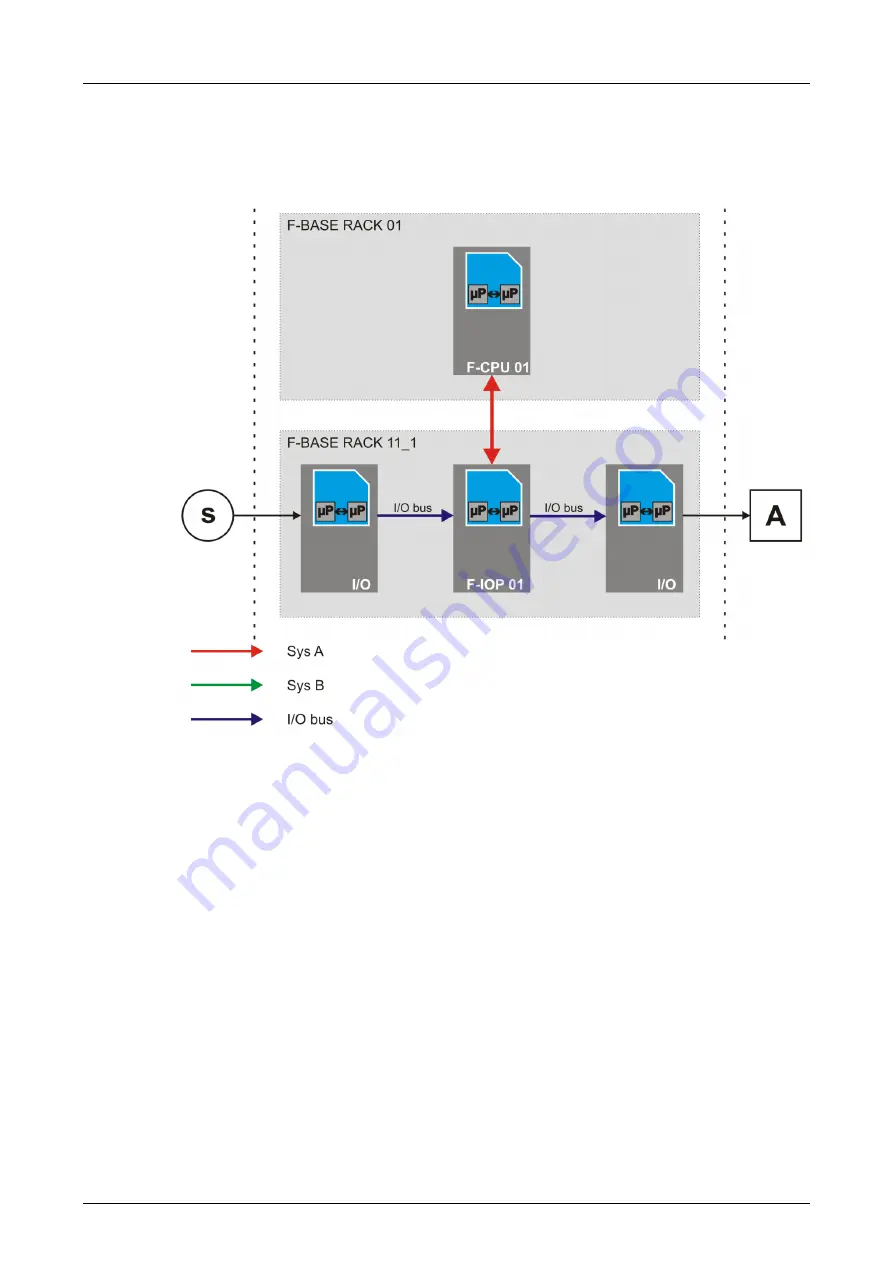

The H51X Mono System

Thanks to the use of safety-related modules (I/O modules, the I/O processing module and a

processor module), the HIQuad H51X system can ensure safety-related signal processing in

accordance with SIL 3 already when operating in a mono structure, see Figure 2.

Figure 2: Example of Safe H51X Mono Operation (1oo2)

The input modules of the HIQuad H51X system safely record the values measured by sensors.

Data is exchanged with the processor module via the I/O processing module. The measured

values are cyclically queried by the processor module and processed by the user program. The

user program's results are sent to the I/O processing module, which writes them to the output

modules. The output modules thus control the field level, e.g., the actuators.

During mono operation, the signal is forwarded by the processor module in slot 8 via system

bus A.

Figure 3 shows the example of an H51X mono system with system bus A. Up to 16 extension

racks can be connected to the system bus in any UP loop, DOWN loop, or UP and DOWN loop.

The extension racks are interconnected with system bus A via the I/O processing module, see

the F-IOP 01 manual (HI 803 219 E).

If the system bus connection is interrupted in a mono system, all I/O modules located after the

interruption point are no longer available. After the interruption point, all output modules enter

the safety-related, de-energized state. As for the input modules, the failsafe initial values are

processed in the respective processor module.

Summary of Contents for HIQuad H41X

Page 1: ...Manual HIQuad X System Manual...

Page 109: ......