S. Himmelstein and Company

Strain Gage Reaction Torquemeters Installation Guide

© 2017 S. Himmelstein and Company—all rights reserved www.himmelstein.com

4

setup like this, reaction torque measurements will be in error to

the extent they, and extraneous load torques, exist. The accelera-

tion error component disappears during constant speed conditions

but, the windage error and extraneous load components are always

present. Only in-line torque measurements are immune to these

error sources. When angular motion is limited and test cycle rates

are low enough to permit “cable windup” without wire fatigue,

reaction sensors are an economic torque measurement solution; see

Figure 4.

A.2 Installation Discussion

To measure reaction torque, one end of the sensor must be

mechanically grounded. The ground may be direct, as in

Figures 1, 2 and 3,

or, it can be through the Load or Driver as in

Figures 5 and 6.

As noted on those figures, the sensor is installed

on the device whose torque is to be measured and the ground is

made via the other device.

A.3 Extraneous Loads

Any force or moment sensor input, other than the reaction torque

is an extraneous load. Depending on the installation, see

Figures

7 and 8

, these could include bending moments and axial thrust

(tension or compression). The Bulletin describing your torqueme-

ter lists the maximum safe extraneous loads that can be applied,

Coupling

Pump

Motor

Reaction

Torquemeter

To Hyd. Load

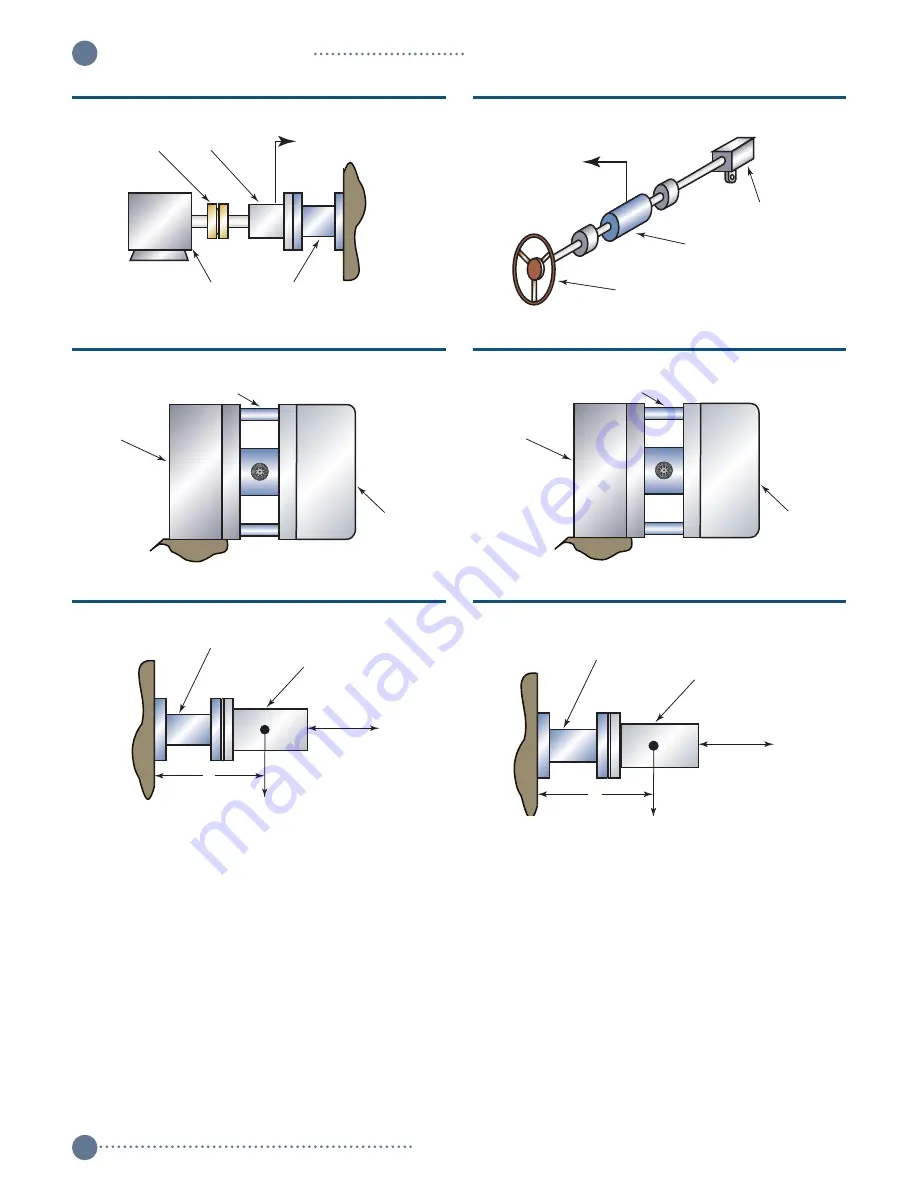

Figure 3. Measuring Absorber Torque

Drive Motor

Torquemeter

Load Device

Figure 5. C-Face Torquemeter Measures Load Torque

Torquemeter

Test Item

F

d

W

Figure 7. Extraneous Load Definition for Flanged Sensor

Torquemeter

Test Item

F

d

W

Figure 8. Extraneous Load Definition for Shaft Sensor

Steering Wheel

To Amplifier

Steering Gear

Reaction

Torquemeter

Figure 4. Reaction Torquemeter Senses Rotating Torque

Load Device

Torquemeter

Test Motor

Figure 6. C-Face Torquemeter Measures Motor torque