Service 27

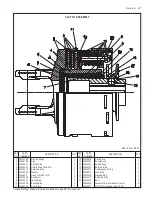

FIGURE 56 PHOTO NO. 3010B

IMPORTANT: DO NOT USE LUBRICANTS, ANTI

SEIZE, AND/OR EXCESSIVE BOLT TORQUE

WHEN ASSEMBLING Q.D. SHEAVES. THESE

CAN BREAK THE ASSEMBLY.

6. Install driveN sheave Item 4 in Photo 3010C

OUTBOARD of bushing’s Item 2 flange. In-

stall driven sheave Item 3 in photo 3010C IN-

BOARD of bushing’s Item 1 flange.

7. Insure woodruff key is in place before sliding

inner bushing on shaft. Align (in/out) the Allen

set screw hole of the bushing being installed

with existing witness marks on its shaft and

torque the set screw.

8. Align 3 UNTHREADED bolt holes Items 5 or 6

with THREADED bolt holes in mating sheave

or bushing. Insert bolts and lockwashers

in these UNTHREADED holes and tighten

about 2 turns each.

9. Alternately torque these bolts, in a uniform

pattern, until the tapers are seated (approxi-

mately 1/2 bolt torque). Check for sheave

alignment and possible wobble. Correct if

necessary.

IMPORTANT: SHEAVE BOLTS ARE ONLY

TORQUED TO GRADE 2 VALUES OF 18-24 Ft./

Lbs. (24-33 N/m.).

10. Continue bolt torquing until above values oc-

cur, or NO LESS THAN 1/8” HUB FLANGE

TO SHEAVE CLEARANCE EXISTS. There

will always be a gap in the inner bushing hub

when proper procedure is followed.

4. Refer to Figure 56, for sheave loosening

procedure and adjust driveR sheave’s in-

ner bushing Item 6 in Photo 3009A in or out

as required for realignment. Then reinstall

sheave per Figure 57, page 28.

FIGURE 55 PHOTO NO. 3009A

SHEAVES REMOVAL/INSTALLATION

1. Loosen belt’s backwrap idler Item 1 in Photo

3010B and remove belts.

2. Loosen and remove bolts from 3 UN-

THREADED holes Item 2.

3. Insert these bolts in the 3 THREADED holes

Item 3. Start with the bolt furtherest from the

inner bushing’s slot Item 4 and gradually al-

ternately torque bolts in a uniform pattern.

Continue torquing in small increments until

the tapered surfaces disengage. The same

procedure is used if driveN sheave Item 5 is

to be removed.

NOTICE: EXCESSIVE AND/OR UNEQUAL

BOLT TORQUES CAN BREAK THE INNER

BUSHING’S FLANGE.

4. The inner bushings are retained with 3/8” Al-

len set screws over their keyways. Remove

the set screw to enable removal of the inner

bushing.

5. For installation refer to Figure 57 page 28,

insure the tapered mating surfaces of the in-

ner bushing Items 1 or 2 in Photo 3010C and

sheave Items 3 or 4 are free of dirt, paint,

rust, metal chips and LUBRICANT.

Summary of Contents for 5710

Page 2: ......

Page 50: ...NOTES 48 Notes ...