Service 29

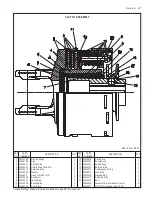

Pack hub cap Item 5 with lube and drive it

home. Continue lubing hub until lube emerg-

es around seal’s outside diameter.

FIGURE 59 PHOTO NO. 3011

GEARBOX

A Gearbox can best be worked on as follows:

1. Detach tractor PTO at gearbox input spline

and remove cross drive shaft shield.

2. Remove the top 4 1/2” bolts holding the

gearbox/PTO input shield and remove it.

3. Remove the bottom 4 1/2” gearbox mount-

ing bolts and slide the gearbox rightward

sufficient to uncouple it from its left splined

coupler. Then slide the gearbox forward and

place it on a workbench.

4. Remove the gearbox drain plug and discard

the lube.

The gearbox has no shims because preload and

backlash are factory set. To service this box pro-

ceed as follows:

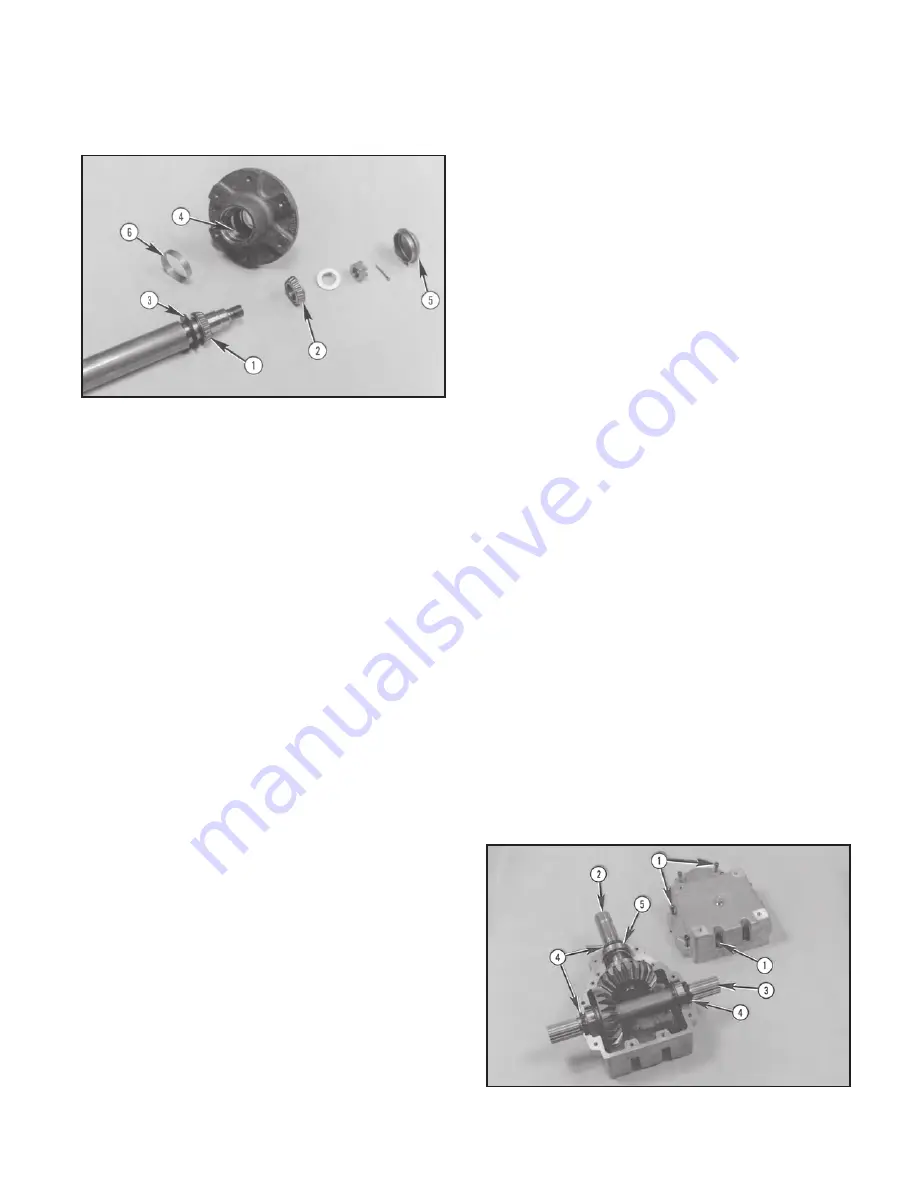

1. Remove (12) 3/8” socket head bolts Item

1 in Photo 3008A holding the (2) halves

together. Tap input shaft Item 2 with a soft

hammer, while holding the output shaft Item

3 off the work table. Be careful to not dam-

age the case’s mating surfaces by prying

them apart.

2. The input and output shafts and gears are

precision fitted. Do not separate them by

prying on an individual set. Lift them apart

together.

3. Remove old anaerobic sealant and com-

plete necessary maintenance. Whenever a

gearbox is opened, all (3) oil seals Item 4

should be replaced. Lube the seal’s inside

diameters before reinstalling and insure

their spring garters are toward the gearbox’s

inside.

4. Clean gearbox of all dirt and metal particles.

Inspect all removed parts for wear. Replace

any bearing showing signs of pitting, inability

to rotate freely and discoloration. Clean any

bearings to be reused and coat with gear

lube. Replace gears showing pitting, breaks

or deformation. Replace input and through

shafts having spline wear or deformation.

5. Whenever shafts are disassembled, make

sure the same thickness snap rings Item 5

are used to maintain backlash and preload.

There is one external snap ring used. For

reassembly, capture bearings and seals in

appropriate machined areas. Tap gently with

a soft hammer to seat, being careful to not

damage seals.

6. After both shafts have been reseated, ap-

ply anaerobic sealant (eg. Locktite 518 (red)

or Perma-Lok HH 190 (dark purple) or Per-

matex silicone sealant 765-1344/1485) to

housing top half and reseat it on bottom half.

Apply pressure, or tap lightly, until top half is

firmly in place. Replace, and retorque the 12

previously removed socket head bolts.

Commercial anaerobic sealants have installa-

tion and SAFETY CAUTIONS on their contain-

ers. These should be adhered to.

FIGURE 60 PHOTO NO. 3008A

Reinstall gearbox in reverse order of removal.

Summary of Contents for 5710

Page 2: ......

Page 50: ...NOTES 48 Notes ...