40 Assembly

1. Allow a SMALL AMOUNT of slack in the

sling and slowly tip the unit forward until its

downward force is being supported by the

sling chains.

IMPORTANT: GROSSLY LOOSE SLING CAN

ALLOW MACHINE TO FALL WITH POTEN-

TIALLY DAMAGING FORCE.

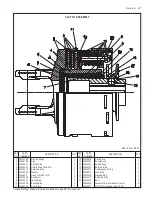

2. After allowing unit to rotate toward the

ground, insert a solid block Item 1 in Pho-

to 3221 approximately 12” high under the

machine’s center. Allow unit to rest on this

block and both blocks Item 2. Do not use

hollow concrete for machine blocking and

ensure everything is STABLE before un-

hooking sling chains.

3. Remove rockshaft dunnage Item 3 and any

remaining dunnage.

FIGURE 78 PHOTO NO. 3221

ROCKSHAFT & WHEEL LEGS

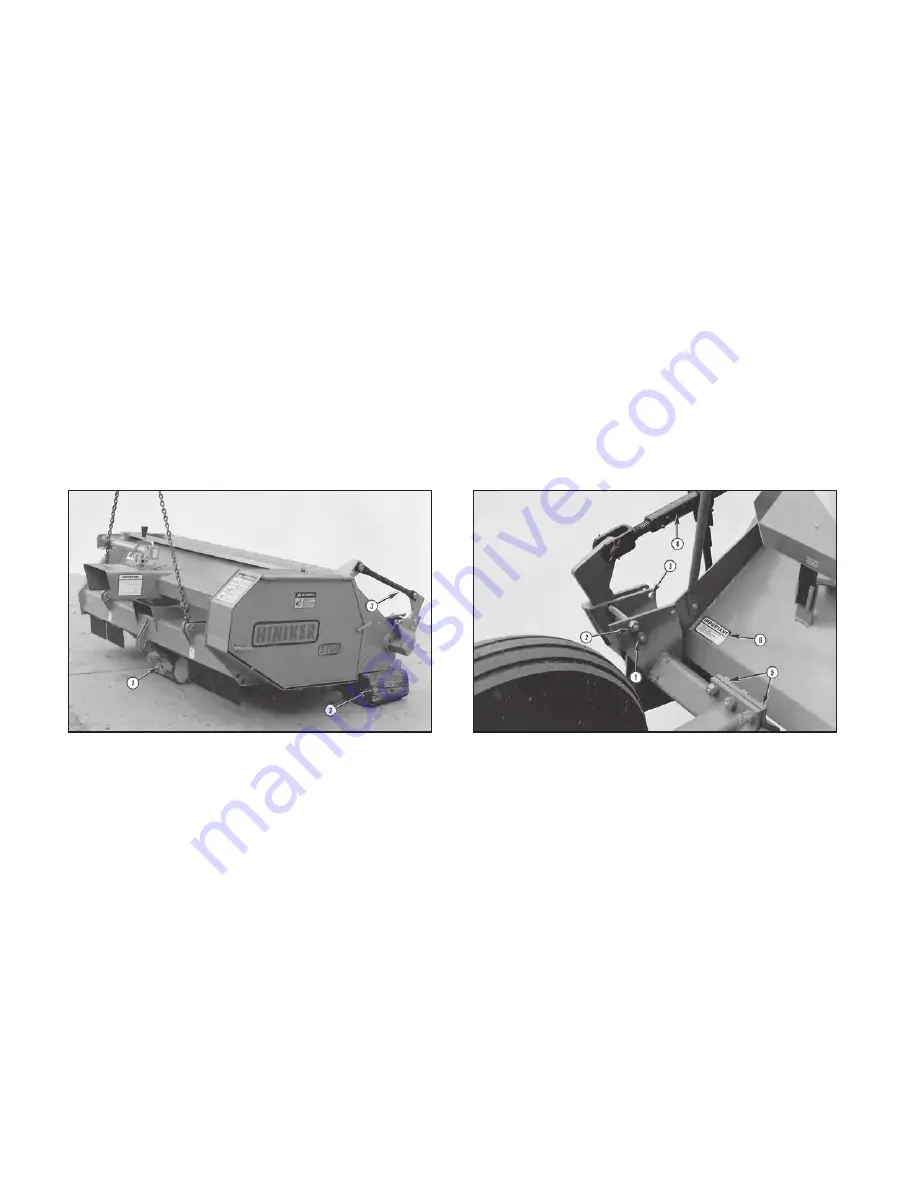

1. Allow both 5/8” x 6” bolts and nuts to remain

in shipping holes Items 1 & 2 as shown in

Photo 3236.

IMPORTANT: AFTER COMPLETING WHEEL

LEGS AND WHEEL/TIRE INSTALLATION,

5/8” X 6” BOLT SHIPPED IN HOLES ITEM 2

SHOULD BE MOVED TO HOLES ITEM 3 FOR

OPERATION AND TOWING. ENSURE BOLT

HEAD IS TOWARD MACHINE CENTERLINE.

2. Install either an accessory ratchet jack Item

4 or an aftermarket hydraulic cylinder. (See

AFTERMARKET HYDRAULICS, page 45.)

3. Contract either ratchet jack or hydraulics to

minimum length. This permits wheel and tire

installation.

4. Each wheel leg is clamped to the rockshaft

with (6) 5/8” bolts, lockwashers and nuts

Item 5. Install wheel legs in their approxi-

mate transverse position; however, do not

torque up their bolts until desired wheel

spacing is determined.

5. The unit is furnished with (2) 15 x 5 wheels,

less tires. The recommended aftermarket

tire size is 6.70 x 15-4PR l1 (implement) or

equivalent. After installing tires on wheels,

it is not desirable to inflate to normally used

implement pressure because wheel load-

ings are light. The machine performs best if

tire pressures are kept no greater than 15-

20 psi, as recommended by decal Item 6.

FIGURE 79 PHOTO NO. 3236

1. The wheels are offset, that is, wheel “dish”

is greater on one side than the other. Install

wheels and tires with the DEEPEST DISH

TOWARD the wheel leg as at Item 1 in Pho-

to 3214. This places its loaded centerline

between the hub bearings. Torque up the (6)

1/2” wheel bolts on each wheel.

Summary of Contents for 5710

Page 2: ......

Page 50: ...NOTES 48 Notes ...