Maintenance & Service Procedures 13

ELECTRIC CLUTCH

The following procedures are recommended to

maximize the life of the electric clutch:

- Remove and clean the electric clutch at

the end of the snow season.

- After cleaning the clutch, coat both mat-

ing surfaces with oil or light grease.

- Remove oil and grease before using the

clutch the following season.

DWG. NO. 6041

When servicing worn clutch components, the

rotor and armature must be replaced as a pair.

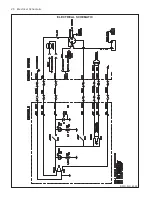

TROUBLESHOOTING CLUTCH PROBLEMS

A. Symptom: Clutch will not Engage

PROBLEM

POSSIBLE CAUSES

- Low voltage

supply

- Zero voltage

- Defective battery

- Faulty charging system

- Bad wiring or connectors

- Broken lead wire

- Open clutch coil, check

coil resistance

- Faulty switch

B. Symptom: Noisy Clutch

PROBLEM

POSSIBLE CAUSES

- Failed bearing

- Adapter plate

rattles against

antirotation pin

- Loose mounting

- Operating Temperature

above 250

O

F

- Bearing Preloaded Axi-

ally

- Some noise is normal: to

reduce noise level, iso-

late antirotation pin from

frame with rubber.

C. Symptom: Clutch Slips

PROBLEM

POSSIBLE CAUSES

- Low voltage

supply

- Contaminat-

ed friction

surfaces

- Clutch loose

on shaft

- Clutch not

mounted

square

- Broken rivet

joints

- Defective battery

- Faulty charging system

- Bad wiring or connectors

- Oil or grease on clutch

- Eccentric collar not locked

onto the shaft

- Mounting shoulder not

square

- Clutch integral key hitting

end of keyway

- Loose mounting

Replace clutch