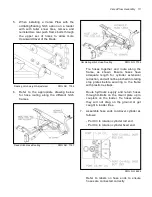

IMPORTANT: Damage to the wiring

harness will occur if adequate cable

length is not provided to allow for

full motion of the loader arms. Use plastic

tie straps to secure the wiring harness to

the loader arm immediately adjacent to the

loader arm pivot point.

Refer to drawing number 7627. Fasten the

square connector next to the hydraulic quick

couplers. Route the cable along the skid-steer

arm to the pivot point of the arm and secure with

the supplied plastic tie straps. It is especially

important to leave adequate cable at the pivot

point to allow for arm movement.

Next, the switch cable needs to be routed into

the cab. Attach the switch to the control arm

using a plastic tie strap as shown in drawing

number 4284.

DWG NO. 4284

Route the third length of the cable to the battery.

Connect the red fused wire ring terminal to the

positive post of the battery and the black wire

ring terminal to the negative post of the battery.

Ensure all wires are away from hot or moving

parts, and secured with plastic ties to prevent

damage.

The wiring on the plow comes preinstalled. The

connectors to the solenoids should be fi rmly

seated. The connectors are interchangeable, as

both solenoids are activated at the same time

when the push button switch is pressed.

8.

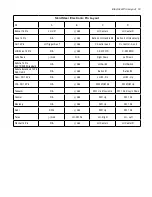

Attach two leveling bars onto the ribs using

provided 5/16 hardware.

DWG NO. 7759

Verify top bar rotates freely on bushing after as-

sembly.

QUICK COUPLERS

Select and install hydraulic quick couplers

and adapter fi ttings on VersaPlow feed lines

according to the size and type (i.e. fl at face or

poppet style) of couplers on customers machine.

Hoses supplied on VersaPlow have 9/16-18

JIC female swivel ends for 9/16-18 JIC male

adapters.

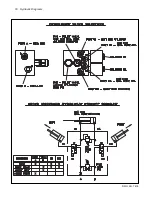

UNIVERSAL CONTROLLER

ELECTRICAL WIRING

Identify the electrical control cable purchased

with the snowplow. It has a square 4-pin

weather pack connector on the fi rst end, two ring

terminals on the second end, and a single push

button switch on the third end.

DWG NO. 7627

14 VersaPlow Assembly