Appendix 2 Reference

A

9

Appendi

x

This section describes how to determine the scaling conversion ratio when measuring with strain

gauges and the Model 8969 Strain Unit.

The appropriate conversion formula for stress depends on how the strain gauges

are used.

Three methods are available depending on whether one, two or four strain

gauges are used for measurement. The two-gauge method is used for tempera-

ture compensation.

E: Young modulus,

ν

: Poisson ratio,

ε

: Distortion measurement value

T

ensile and Compressive Stress Measurement: Stress (

σ

) = E ×

ε

For temperature compensation with two or four gauges, position the gauges per-

pendicularly.

Stress (

σ

) is obtained by 1 / (1 +

ν

) for two gauges, and by 1 / {2 (1 +

ν

)} for four

gauges.

Bending Stress Measurement: Stress (

σ

) = E

×

ε

For temperature compensation with two or four gauges, stress (

σ

) is obtained as

a multiple of ½ or ¼, respectively.

Torsional Stress Measurement: Stress (

σ

) = E / {2 (1 +

ν

)} ×

ε

(two-gauge case)

For the four-gauge case, it is half of that.

Refer to the strain gauge instruction manual for combinations of strain gauges

for each measurement.

Example. Measuring Compressive Stress

Using the one-gauge method for an aluminum measurement object having a

Young's modulus of 73 (GPa) according to the following Table,

σ

= 73 × 10

9

× Measurement Value (in

με

units) × 10

-6

(in

με

units)

) = 73 × Measurement Value (in kPa units)

= 7.44

*

× Measurement Value (in gf/mm

2

units)

*:

1 Pa =

1.01971621× 10

-7

kgf/mm

2

Unit: gf/mm

2

, Conversion Ratio = 7.44 gf/mm

2

Enter this value as the scaling conversion ratio

See:

"8.5 Converting Input Values (Scaling Function)" (

Appendix 2.5 Scaling Method When Using Strain

Gauges

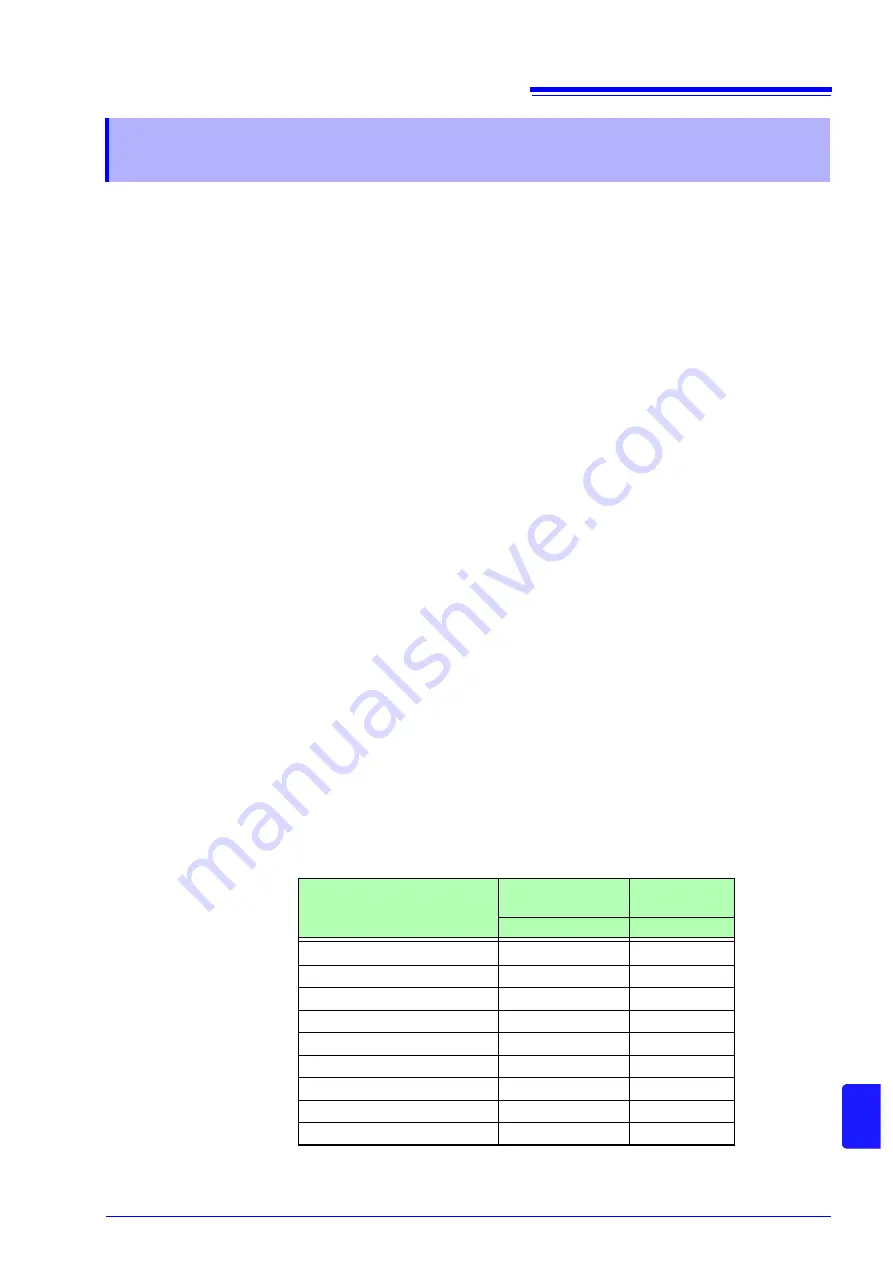

Mechanical properties of industrial materials

Material

Modulus of Elasticity

(Young's Modulus)

Poisson's Ratio

E (GPa)

ν

Carbon Copper (0.1 to 0.25% C) 205

0.28 to 0.3

Carbon Copper (> 0.25% C)

206

0.28 to 0.3

Spring Steel (Quenched)

206 to 211

0.28 to 0.3

Nickel Steel

205

0.28 to 0.3

Cast Iron

98

0.2 to 0.29

Brass (Cast)

78

0.34

Phosphor Bronze

118

0.38

Aluminum

73

0.34

Concrete

20 to 29

0.1

Summary of Contents for 8847

Page 1: ...MEMORY HiCORDER Instruction Manual 8847 December 2010 Revised edition 4 8847A981 04 10 12H ...

Page 2: ......

Page 18: ...Operating Precautions 8 ...

Page 26: ...1 4 Basic Key Operations 16 ...

Page 74: ...4 4 Waveform Observation 64 ...

Page 98: ...5 5 Managing Files 88 ...

Page 110: ...6 6 Miscellaneous Printing Functions 100 ...

Page 126: ...7 8 Seeing Block Waveforms 116 ...

Page 160: ...8 10 Making Detailed Settings for Input Modules 150 ...

Page 198: ...10 6 Numerical Calculation Type and Description 188 ...

Page 296: ...15 7 Controlling the Instrument with Command Communications LAN USB 286 ...

Page 304: ...16 2 External I O 294 ...

Page 362: ...Appendix 5 FFT Definitions A28 ...

Page 368: ...Index Index 6 ...

Page 369: ......

Page 370: ......

Page 371: ......