5

●

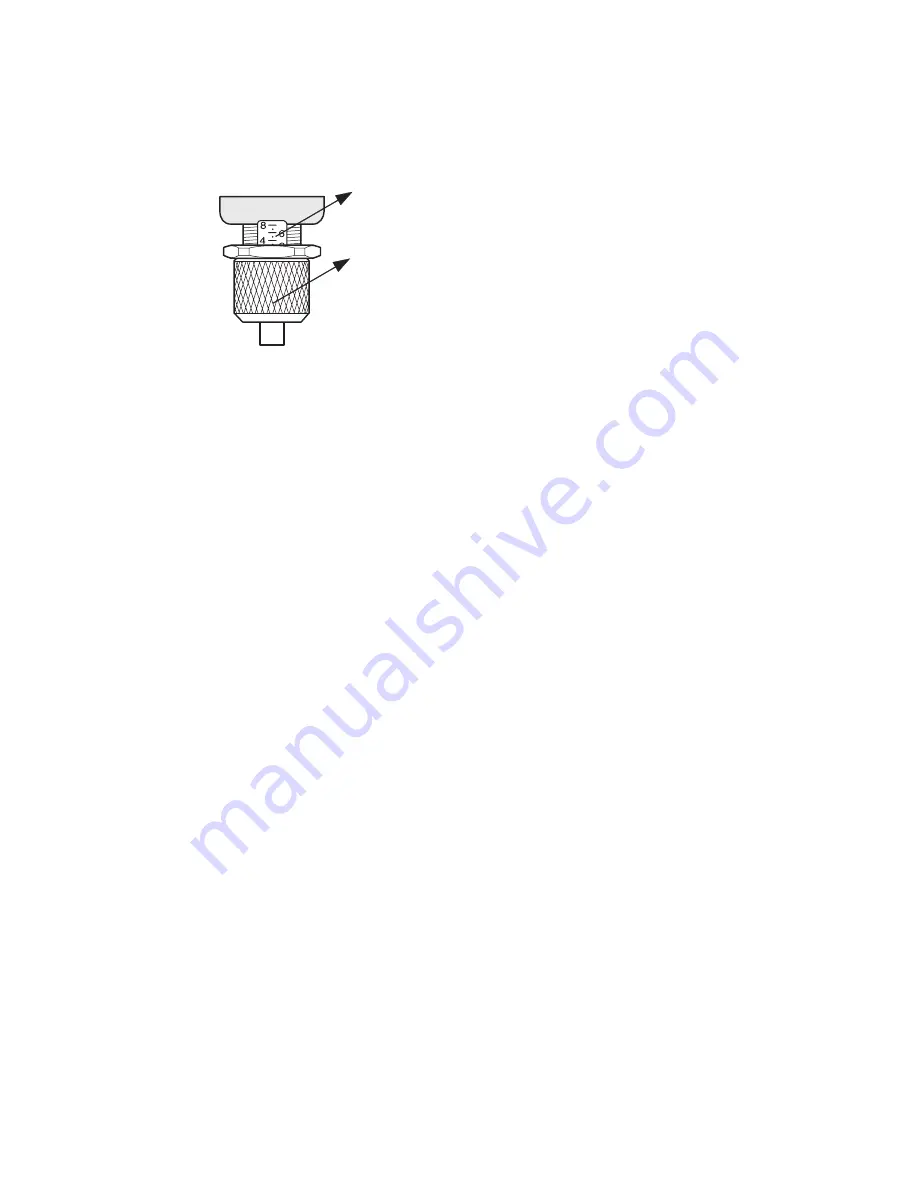

The CL-2000 (SS-2000) Electric Screwdriver have

‘Double nut system’ (Nut fixing ring and Torque adjust-

ing nut) to avoid loosening from shock or vibration to

the driver. To adjust those two nuts, follows

①

to

③

steps below.

At first, stop the Nut fixing ring upper

surface to fit the graduation, if you

want to adjust.

Then turn the Torque adjusting nut so

as to push up the Nut fixing ring.

Lastly, to avoid the loosening of the

‘Torque adjusting nut’ strongly fas-

ten the Nut fixing ring’ by holding the

‘Torque adjusting nut’.

5. Push-to-Start Type

Both the models of Driver have Push-to-Start type that is

designed to start by causing a proper thrusting pressure on

the bit in place of pressing the Switch Lever by the fore-

finger. Drivers of this type are identified by the additional

sign PS following the principal Push-to-Start type models.

The PS type, therefore, has no lever for starting. All other

functions remain same as the principal type.

Users of this type is specifically cautioned to disconnect the cord

to shut off power when handling the Quick Change Collet for

replacing bit to avoid danger from surprising starting.

6. Power Supplies

The power pack for CL Drivers requires two basic func-

tions: (1) to convert local AC power to lowered DC Power

and (2) to shut off the power by automatical reaction to the

pulse emitted from the Driver at the moment the torque at

work reaches the regulated limit. The function (2) can be

performed, if so opted, by a ready-made unit called Control

Box CB-105 installed separately from the unit for the func-

tion (1).

①

②

③