- 8 -

■

Torque Adjustment

Torque is controlled by the tension on a spring inside the

torque adjustment nut. If set the nut tighter, the output torque

is higher.

• The adjustment torque scale does not give the actual

output torque. Please regard the output torque graph as

an approximate guide.

■

Torque Adjustment Procedure

1. If you have a predetermined torque value, set that value

on the scale using the torque adjustment nut.

• The BL-2000 Electric Screwdriver have ‘Double nut

system’ (Nut fixing ring and Torque adjusting nut) to avoid

loosening from shock or vibration to the Screwdriver.

●

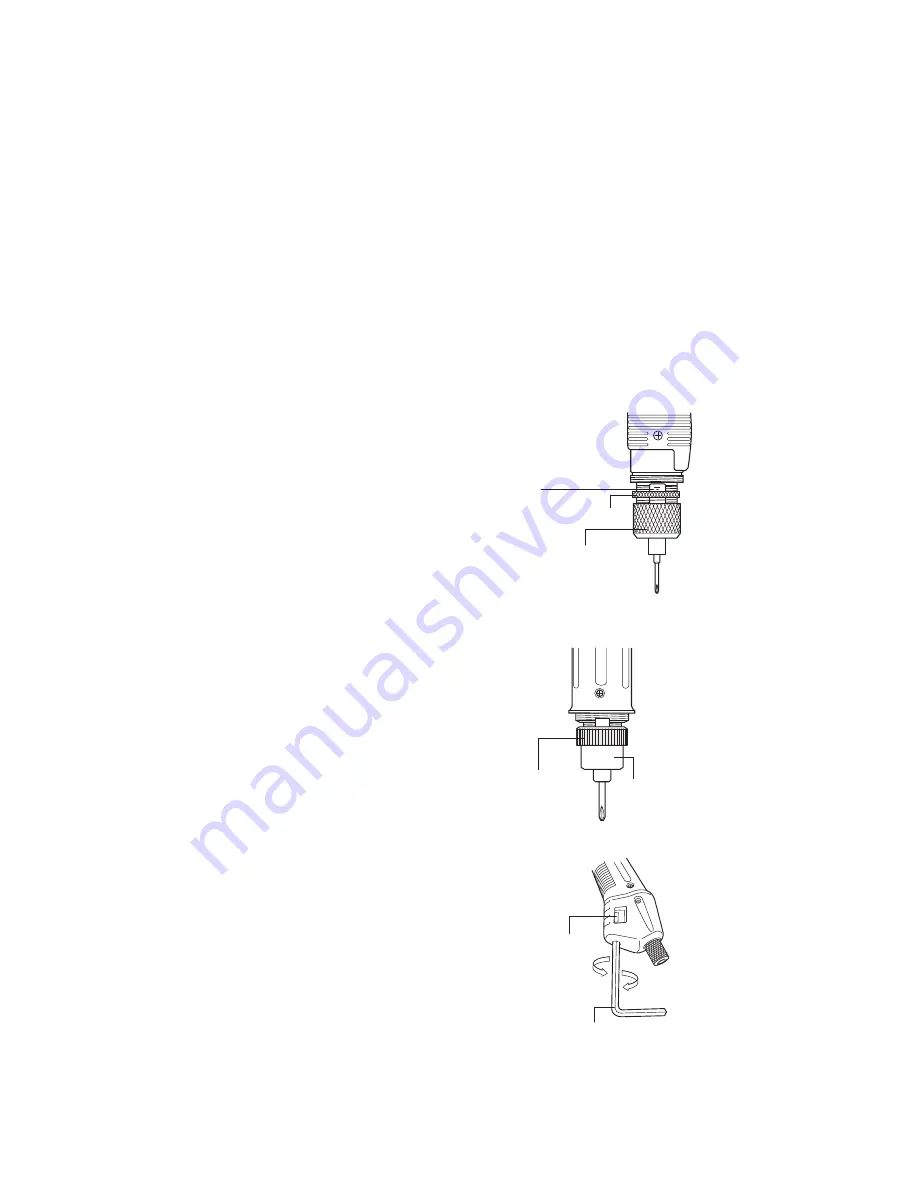

BL-2000

• At first, keep the Nut fixing ring

to fit the scale at which, if you

want to adjust.

• Then turn the Torque adjusting

nut toward the Nut fixing ring.

• Lastly, to avoid the loosening of

the ‘Torque adjusting nut fasten

strongly the Nut fixing ring by

holding the ‘Torque adjusting

nut’.

●

BL-3000

If using model BL-3000, make

the setting by pushing the nut

collar upwards, removing the

t o r q u e a d j u s t m e n t

nut

and turning it so the

point over the nut aligns

with the groove.

●

BL-5000, BL-7000

If using model BL-5000 or 7000,

set the torque adjustment nut

using the hex wrench that is

provided.

Torque scale

BL-2000

Torque

adjustment nut

Nut securing ring

BL-3000

Torque

adjustment nut

Nut securing

ring

Torque

adjustment

scale

5 mm hex nut L wrench

Summary of Contents for BL-2000

Page 11: ... 11 ...

Page 12: ... 12 ...