- 7 -

Precautions for Safe Operation

1. Check that the power is off before changing the bit. It takes only a slight amount of pressure for a push-to-

start driver to go into operation. Accidental pressure on the tool could result in the high-speed bit causing

unexpected damage. Before touching the bit always check to see that the power is turned off or the

power

switch

(FOR/OFF/REV) is set to the off position in the middle.

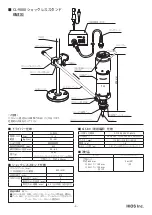

2. This high-torque tool delivers considerable punch. It should be operated only when the

stand base

is

securely bolted to a sturdy work bench.

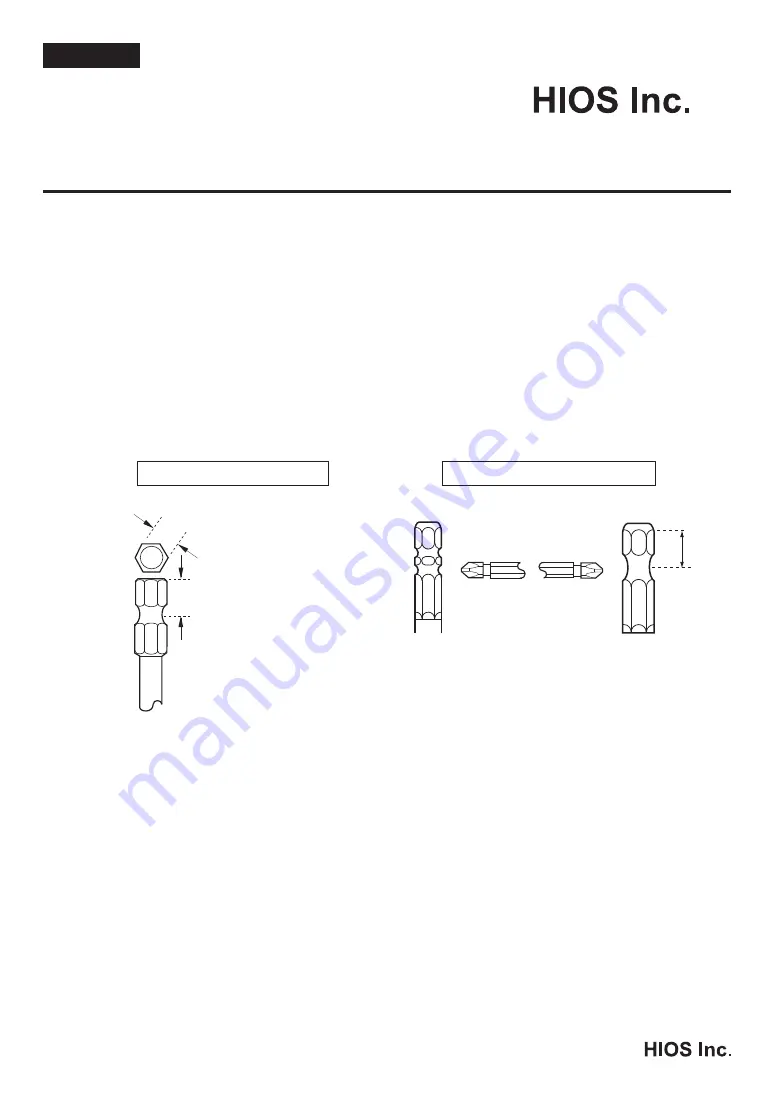

3. For safe operation use bits conforming to the standards indicated in the diagram on the left below. The

diagrams on the right indicate bits that cannot be used with the CL-9000 driver.

English

High Torque Electric Screwdriver

CL-9000

Push-to-Start Type

(comes with shockless stand)

1-35-1 Oshiage, Sumida-ku Tokyo,

Japan

TEL: 81-3-6661-8821

FAX: 81-3-6661-8828

Bits for use with CL-9000

Bits unsuitable for CL-9000

6.35

9.0

9.0

Use size 6.35 mm hexagonal

bits whose length from the

point to the bearing groove

are 9 mm.

Bits whose length from

the point to the bearing

groove is not 9 mm.

W bit

Double recess

bearing groove

4. To protect the functioning of the tool and transformer and insure their safe operation, never use them in an

environment where they might be penetrated by water, oil, etc.

5. Dropping the tool or subjecting it to strong impacts can harm it. Please exercise care it handing it and the

transformer.

6. When reversing direction of rotation, first set the

power switch

to the off position between FOR (forward)

and REV (reverse) and wait until the driver has completely stopped turning.

7. The CL-9000 driver uses external carbon brushes that cannot be replaced by the user. In order to avoid

deterioration of insulation from brush wear, we recommend that the tool be sent to your Hios dealer for

replacement (1) after about 1 million operations, (2) when your Hios repairman recommends replacement

upon an annual maintenance check, (3) when the tool begins to show irregular rotational movement, the

motor sound is abnormal, there is overheating or the tool is no longer operating at full strength.

8. Be sure to ground the tool.