■

Operation parameters

23

/

52

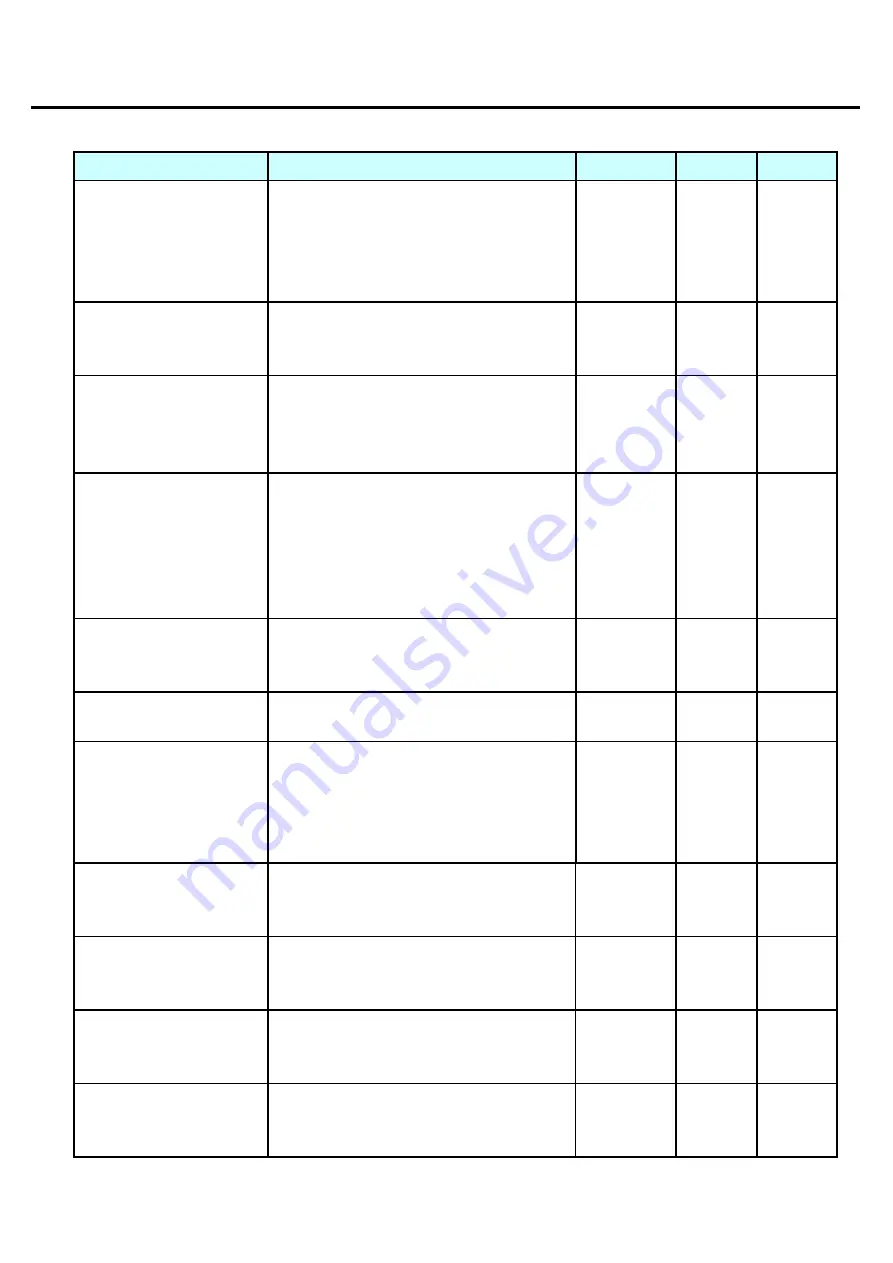

■ Parameter setting range for special settings

Parameter name

Description

Default value Min. value Max.value

1st hold time w/rev

(Holding time for first full

tightening in operation

patterns that include reverse

rotation: ms)

Holding time setting for the first full tightening in

operation patterns that include reverse rotation

* See Chapter 15 "Holding time"

100

50

500

Tmp chat period

(Chattering judgment period

for temporary tightening: ms)

Period setting of one scan in the current

chattering judgment for temporary tightening

* See Chapter 16

1

1

50

Tmp chat counter

(Chattering judgment count

for temporary tightening:

number of times)

Setting for number of scans to perform in the

current chattering judgment for temporary

tightening

* See Chapter 16

5

0

100

Full/Add – Specified current

(Negative current value used

for judgment of whether the

specified current is reached

in full tightening and

additional tightening: -%)

Parameter setting used in the calculation of the

current for judgment to increase the torque-up

detection speed for full tightening and additional

tightening

10

0

50

Reverse Speed

(Reverse operation speed:

rpm)

Speed setting for reverse operation

200

1

999

Motor KT (spec)

(Motor KT value: N.m/A)

KT value setting of the motor that is used

(Refer to the motor specifications)

0.42

0.001

1.000

Motor KT offset

Motor KT high/low

(Motor KT value offset

+ setting torque-down

- setting torque-up)

Set the positive and negative offset value to

apply to the motor KT value.

This corrects for the difference between the

motor torque and actual tightening torque.

The unit is N.m/A.

0

-1.000

1.000

Torque Coeff

(Torque command correction

slope coefficient)

This correction value is applied to the torque

command to stabilize it. (Perform calculation

using the correction value calculation file.)

Factory

setting

-32768

32767

Torque offset Coeff

(Torque command correction

offset value)

This correction value is applied to the torque

command to stabilize it. (Perform calculation

using the correction value calculation file.)

Factory

setting

-32768

32767

Motor Torque Coeff

(Motor torque correction

slope coefficient)

This coefficient corrects for the difference

between the motor torque and actual tightening

torque.

Factory

setting

-32768

32767

Motor Torque offset

(Motor torque correction

offset value)

This offset value corrects for the difference

between the motor torque and actual tightening

torque.

Factory

setting

-32768

32767

Summary of Contents for DCD-40L

Page 1: ...Current Controlled Screwdriver DCD 40L 115W Instruction Manual ET A070 19A HIOS Inc ...

Page 27: ... Operation timing charts 27 52 Pattern 2 ...

Page 28: ... Operation timing charts 28 52 Pattern 3 ...

Page 29: ... Operation timing charts 29 52 Pattern 4 ...

Page 37: ... I O 37 52 Timing chart for normal operations when torque judgment is NG ...

Page 38: ... I O 38 52 Timing chart when emergency stop signal is input ...