- 4 -

(9)

No Error Time

for double fastening

No error time can be set with three bars + values in order to avoid unnecessary

errors during double fastening.

・

This setting is enable only when fastening is done properly.

・

Display range: 0.0

-

9.9

・

Setting range: 0.0

-

9.9 sec

■

Screw Counter

1.

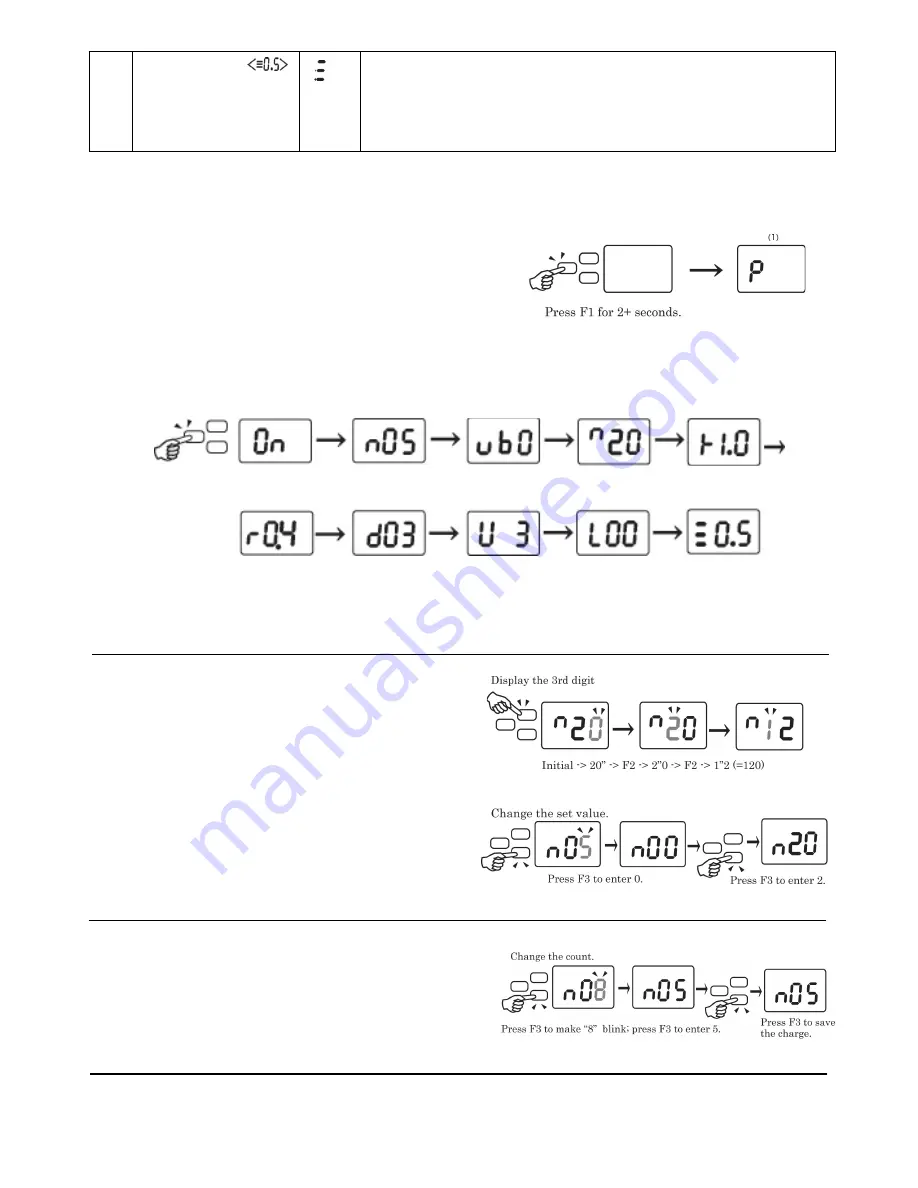

Changing to the Setup Mode:

Press and hold the F1 Button until “P” then the

“On” is displayed.

2.

Setting Mode:

Pressing the F1 button allows you to scroll through each setup functions.

Refer to “List of setup functions” on page 3 for the changing and setting any functions.

Note: The no. of motor revolutions is displayed up to triple digits.

3. Value Setting for Each setup functions:

●

Verify the hundreds (3

rd

) digit.

Press the F2 Button to change the figure position

for setting.

●

Change the value.

Pressing the F3 button increases the value one by one.

Press and hold the F1 button until the buzzer sounds

twice to save the change.

4. Change cycle count.

Press F1 Button for more than 2 sec. to increment to

display number. Follow the procedure described in

3 above.

The count can be set between 1 and 99.

(Count )

(

Pulse/ Min

)

(

Pulse/ Max

)

(Work Reset Timer)

(Reverse Count Timer)

(System)

(Over Time/

(Total No. of the

(No Error Time for

Short Time)

driver shut off) double fastening)

(1) (2) (3)

※

(3)

※

(

4

)

(5) (6) (7)

(8)

(

9

)

(Count)

(Min. revolutions)

(Max. revolutions)

(Work Reset Timer)