9

Version: 2016-UK-2

Handling of load (use of hydraulic cylinders)

The Winlet 350TH is equipped with an electro-hydraulic system which makes it possible to move the lifting

arm of the machine in 4 different directions:

1.

Main cylinder, which positions the item roughly in the vertical position.

2.

Telescopic cylinder, which moves the item forward along the longitudinal axis of the machine.

3.

Tilting cylinder, which moves items from a horizontal floor

–

to a horizontal ceiling (180

degrees).

4.

Fine-adjustment cylinder, which moves the item in a 100% vertical line.

Winlet 350TH also has a

multi-mobile front

, which makes the item manually maneuverable in all

dimensions. The front can be shifted sideways, turned 90 degrees to right and left, and rotated 360 degrees,

without limitation.

Use of hydraulic cylinders

Press the desired cylinder on the operating panel. An LED lamp will now show the selected cylinder. The

cylinder can then be moved in the desired direction at the desired speed by engaging the direction and

speed regulator.

Take note of the following points:

The working area must be clear of any people and/or objects.

Danger of injury by collision!

Never step under a hovering load!

Danger from falling load!

If the vacuum level in only one of the 2 vacuum circuits drops below 60%, put the load down

immediately

!

If one of the red lamps lights up, put the load down

immediately

!

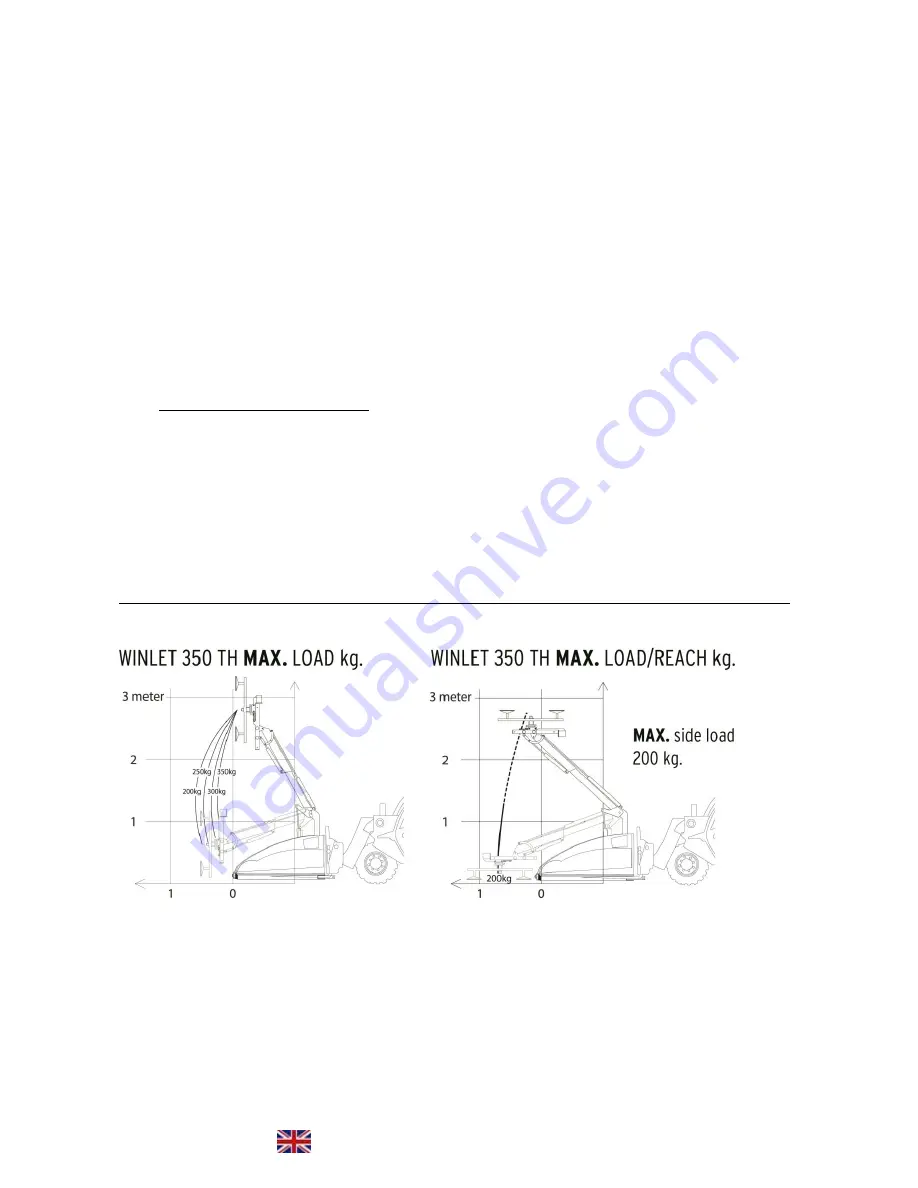

Note: Be aware that the capacity of the machine is reduced when using the hydraulic cylinders

.

The stated values are for reference. And based on a 100% level surface.