1

In operation the sanding belt is held in place on the

sanding drum by centrifugal force. It is very important

that the drum rubber and abrasive guides are

maintained in good condition at all times.

Store and transport the HT8 EX with a sanding belt in

place at all times to protect the drum rubber. If the

machine is stored for long periods, use a small wedge

under the main frame to keep the drum off the floor.

This will prevent the drum developing a flat spot.

1.

Check that power supply is disconnected. Tilt the

machine back and rest the handle on the floor.

Open the drum guard and remove the abrasive

belt if fitted. Inspect the condition of the drum

rubber. A damaged or worn drum rubber must

be replaced to maintain machine performance.

A damaged or worn drum rubber can result in

poor sanding performance with subsequent

damage to the floor surface and can be

dangerous in operation.

If the machine moves from side to side when

sanding or you are experiencing inconsistent

sanding performance this can indicate a worn or

damaged drum rubber. This is caused because

the drum rubber is not gripping the sanding belt.

2.

To replace the drum rubber contact your local

Hiretech Service Agent.

Hiretech operate a

simple exchange program to replace HT8 EX

Sanding Drums.

Please contact your local

service agent for information, service levels and

pricing. For further information visit.

http://www.hiretech.biz/products/ht8_ex_drum

_service.html

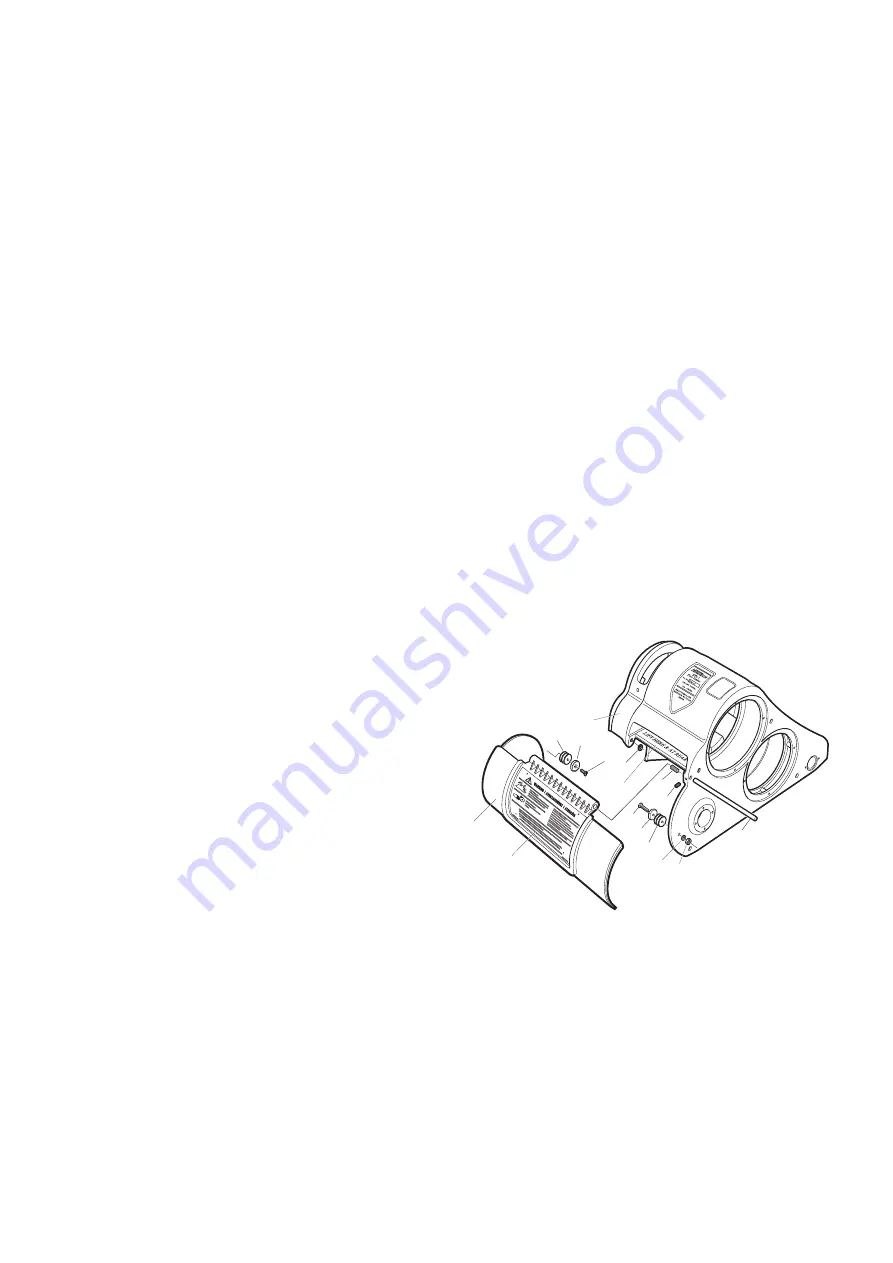

3. Check the condition of the Abrasive Guides

(Ref.142). It is very important that the Abrasive

Guides are maintained in good condition. The

Abrasive Guides ensure that the abrasive belt

runs evenly and centred on the sanding drum.

Worn Abrasive Guides will cause wear to the

drum rubber, result in poor sanding

performance and cause damage to the machine

and floor surface.

Worn guides will also

damage the abrasive belt and may cause it to

tear.

The Abrasive Guides should not be worn by more

than 3mm (1/8”). The thickness from new is

7mm (1/4”).

4.

When fitting new Abrasives Guides or when

replacing the Drum Guard (Ref. 35) ensure that

the correct gap is maintained between the edge

of th sanding drum and the Abrasive Guides .

Remove abrasive belt if fitted, using the Spacer

Guide Abrasive (Ref.143) adjust the gap

between the Abrasive Guide and the edge of the

sanding drum on both sides of the drum as

follows;

200mm wide abrasive - gap 1.5 to 2.5mm

8in wide abrasive - gap 3/32 to 5/32in

The Spacer Abrasive Guide are of various

thicknesses.

User the thicker guides first and

adjust the gap using the thinner spacers if

required.

5.

Check the condition of the rear wheels (Rollers

Ref.61). The wheels must be free from dirt and

rotate freely. Check the condition of the Shaft

Roller Ref.60, use a straight edge to make sure

the shaft is not bent.

For a detailed parts drawings, parts lists, service

bulletins and technical support visit Hiretech on the

web at http:// www.hiretech.biz

36

35

28

80

29

142

152

144

142

143

143

145 146

74

66

27

Drum Guard & Abrasive Guides