15

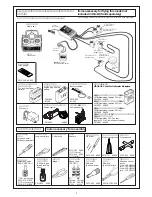

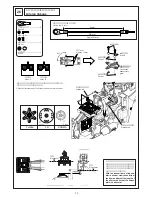

エンジンの組立

Engine assembly

7

M3X12CS ............................. 4

M3X8CS ............................... 2

M3X6

皿ネジ ........................

4

M3X6 countersunk screw

FWø6Xø13X1 ...................... 1

M2X12PH ............................. 1

ø5

ボール ..............................

1

ø5 ball

M2

ナット .............................

1

M2 nut

DA

ボール台 ........................

1

DA ball stand

FW ø6Xø13X1T

M3X8CS

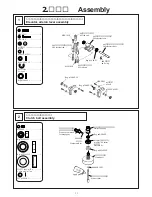

エンジン

Engine

フライホイール

30

クラスエンジン用

Flywheel for 30 class engine

M3X6

皿ネジ

M3X12CS

M2X12PH

M3X6 countersunk screw

クーリングファン

Cooling fan

クラッチシュー

Clutch shoe

エンジンマウント

Engine mount

M3X12CS

M2

ナット

M2 nut

ニードル延長レバー

Needle extension lever

M3

セットスクリュー(エンジン付属)

M3 set screw (included with engine)

ø5

ボール

ø5 ball

レバー

Lever

DA

ボール台

DA ball stand

ドライブナット

(エンジン付属)

Drive nut (included with engine)

Lock

Lock

Lock

Lock

エンジンに付属のワッシャー

を使用してください。

Use the supplied washer for the

engine.

別売のクランクロックを使

用して締め込みます。

Fasten by using a crank

l o c k w h i c h i s s o l d

separately.

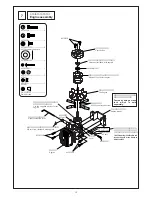

スロットルロッドがメイン

フレームに干渉する場合に

使用し、高さを調整します。

Use this parts when throttle rod

interferes with main frame to

adjust height.

Summary of Contents for Lama SA-315B

Page 71: ......