32

SWMのリンケージ-2

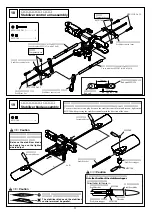

SWM linkage -2

27

注意

Caution

使用するサーボによって、ロッドの長さは多少変わりま

すので、サーボに合わせて微調整を行ってください。

The lengths of the rods vary to some degree depending

on the servos used. Fine-tune them accordingly.

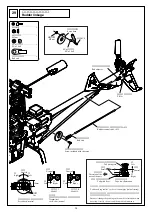

ス ワ ッ シ ュ プ レ ー ト

が 直 角 に な る よ う に

長さを調節する。

Adjust the length so

that the swash plate

is perpendicular.

・

SWM

ロッド③を取付調整後、機体を正面から見て、スワッ

シュプレートがマストに対して直角であることを確認して

ください。

・傾いている場合は

25

で取付けた

SWM T

型レバー

/

スワッシ

ュロッドの長さを調節し、直角にしてください。

・

After having conducted installation adjustments on the SWM rod

③

, looking at the unit from the front, make sure the swash plate

and the mast are perpendicular to each other.

・

When inclined, adjust the length of the SWM T-type lever/swash

rod installed in section 25 and set it perpendicular.

モード

I

Mode I

モード

II

Mode II

ニュートラル

Neutral

送信機のスティックの位置

Position of the transmitter stick.

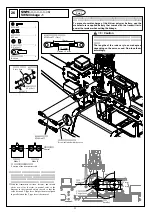

サーボホーン

Servo horn

M2

ナット

M2 nut

EX ø5

ボール

EX ø5 ball

M2X6CS

・送信機のエルロン、エレベーター、ス

ロットルの各スティック、およびトリ

ムがニュートラルの時、右図のように、

T

型レバーが水平のときにサーボホーン

と

T

型レバーのボール位置が平行になる

ように、ロッドの調整をしてください。

・

With the transmitter’s aileron, elevator, and

throttle sticks as well as the trim in neutral,

refer to the diagram in the right and adjust

the rod so that the servo horn and T-type

lever ball positions are aligned in parallel

when the T-type lever is horizontal.

約

0mm

Approx. 0 mm

SWM

ロッド③

(2

セット

)

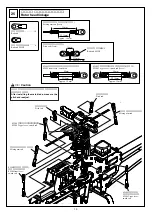

SWM rod

③

(2sets)

SWM

ロッド③

SWM rod

③

16mm

M2X6CS ............................. 2

M2

ナット

........................... 2

M2 nut

EXø5

ボール

....................... 2

EX ø5 ball

ロッドエンド

..................... 4

Rod end

90

°

90

°

90

°

90

°

T

型レバー

T-type lever

正面から見た図

Front view illustration

平行

Parallel

水平

Horizontal

12.5 mm

12.5 mm

サーボに付属のネジ

Screw included with the servo

Summary of Contents for Lepton EX

Page 12: ...0 1 2 34 5 6 7 8 8 8 8 8 8 9 9 Skid...

Page 23: ...0 1 1 0...

Page 47: ...0...

Page 59: ...58 3 3 1 5 Repair parts...

Page 75: ......