30-1

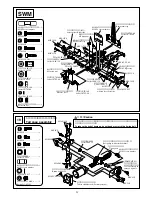

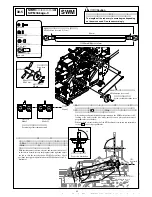

SWMのリンケージ/送信機の初期設定

SWM linkage / Transmitter initial setting

スワッシュモードでは、

スワッシュミキシングのための送信機の初期

設定が必要です。

ここでは各リンケージのプリセットを行うため、

各社送信機のデータ

シートを基に送信機の初期設定を行います。

送信機にデータを入力する際は、まず最初にスワッシュタイプ

を選択して下さい。

Before inputting data to the transmitter, first select the swash

type.

本機のスワッシュタイプは図のようになっています。

The swash type this model is shown in the illustration.

ピッチカーブ、スロットルカーブの入力は

34

でおこないます。

先にピッチカーブ、スロットルカーブを入力すると、サーボホーン

取付の際、ニュートラルがずれるおそれがあります。

機首方向

Nose

Check

チェック

120

°

120

°

120

°

Refer to each transmitter's manual for how to input.

In addition, the values change depending on the combination of transmitter,

receiver, servo, gyro, etc., and machine type, and fine adjustment for each

needs to be done.

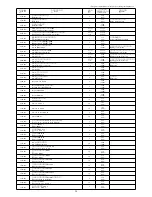

送信機別データシート

Transmitter data sheets

Swash mode requires the initial setting of the transmitter for swash mixing.

This section explains the initial setting of the transmitter in accordance with

the data sheets of each manufacture's transmitter in order to carry out the

presetting of each linkage.

Inputting the pitch curve and throttle curve is carried out in

34

Inputting the pitch curve and throttle curve first during a servo

horn installation may shift the neutral position.

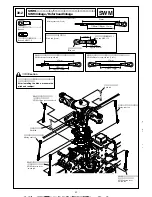

REVERSE SW

TRAVEL

ADJUST

SWASH

Mix

135%

100%

100%

100%

140%

140%

100%

100%

60%

-60%

70%

100%

100%

100%

100%

THRO

AIL

ELEV

RUDD

GEAR

PIT

THRO

AIL

AIL

ELEV

ELEV

RUDD

GYR

PIT

PIT

REV

REV

NORM

NORM

NORM

REV

REV

REV

NORM

NORM

REV

REV

END POINT

FUTABA FF9-H Super

JR PCM9X

(R / U)

(L / D)

(H / L / D)

(L / R / U)

EXP

INH

TYPE

GAIN

AILE

ELEV

PITCH

3s

REVERS

SWASH

TYP:SR-3

CP3F

CP-EPA

H

L

SWASH

AIL:+70%

ELE:-70%

PI:+50%

100%

100%

NORM

100%

100%

REV

100%

100%

NORM

100%

100%

NORM

100%

100%

REV

1ch

2ch

8ch

7ch

100%

70%

REV

3ch

4ch

5ch

6ch

SANWA STYLUAS

(H / L / D)

REV

EPA

(L / R / U)

120%

95%

100%

100%

125%

125%

100%

100%

75%

75%

75%

75%

110%

110%

100%

100%

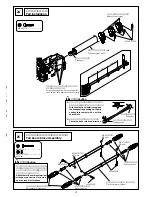

プロポの初期設定が済んだら、

サーボが正しい方向に動作するかチェッ

クしましょう。仮にサーボホーンを付けると、動く向きがわかりやすく

なります。

After the transmitter initial setting is completed, check to see that the servo

drives in the proper direction. Temporarily attaching the servo horn facilitates

seeing the driving direction.

図と動きが一致しないときは、

サーボの回転方向が逆になっています。

その場合、送信機側でリバーススイッチの設定をしましょう。エルロ

ン、エレベーター、ピッチの場合はその他にミキシング量の調整が必

要となります。

(各送信機の説明書を参考にセッティングして下さい。

)

When the movement does not agree with the figures, the rotation direction of the

servo is reversed.

Adjust the rotation direction with the reverse switch of the transmitter. Besides

that, adjustment of the mixing is required for the aileron, elevator, and pitch.

(Refer to the manual of each transmitter).

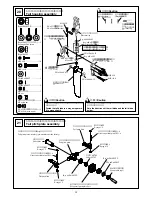

サーボの動作確認

Setting and Servo Movement

入力のしかたは各送信機の説明書をご覧下さい。

また、数値は送信機、受信機、サーボ、ジャイロ等の組み合わせや

機体により、値が変わりますので、個々の微調整を行って下さい。

モード

I

確認する箇所

Check points

サーボホーンの動き

Servo horn movement

エルロン

Aileron

エレベーター

Elevator

ピッチ

Pitch

スロットル

Throttle

ラダー

Rudder

MODE II

スロットルレバー

Throttle lever

スワッシュプレートを横から見た図

Side view of the swash plate

スワッシュプレートを後ろから見た図

Back view of the swash plate

41

SWM

Summary of Contents for SCEADU Evolution EX H.P.M

Page 3: ...2...

Page 4: ...3...

Page 5: ...4...

Page 6: ...5...

Page 7: ...6...

Page 53: ...52 5 Repair parts 52...

Page 75: ...MEMO 74...