40

⑨

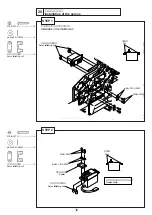

スロットルレバー

Throttle lever

サーボに付属のネジ

Screw attached to the servo

機首方向

Front side

カット

Cut

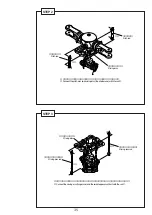

スロットル A

フルハイ位置

Throttle A

Full high

スロットル B

アイドリング位置

Throttle B

Idling

スロットル C

エンジンストップ位置

Throttle C

Engine stop

13mm

ロッ

ク

M2×6 CS

サーボホーン

Servo hone

EX φ5ボール

EX φ5 Ball

M2ナット

M2 Nut

A

B

C

S

スロットルサーボ

Throttle servo

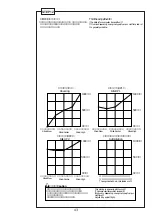

モードⅠ

MODEⅠ

モードⅡ

MODEⅡ

モードⅠ

MODEⅠ

モードⅡ

MODEⅡ

モードⅠ

MODEⅠ

モードⅡ

MODEⅡ

モードⅠ

MODEⅠ

モードⅡ

MODEⅡ

モードⅠ

MODEⅠ

モードⅡ

MODEⅡ

④ エンコンサーボホーンの位置を調整します。サーボホーンのスプラインで角度を合わします。Sを中心にA

とBは同じ角度にします。

④ Adjust the position of the engine-control servo horn. Adjust the angle using the spline of the servo horn. The angles A

and B from the point S should be equal.

⑤ サーボホーンにEXφ5Ballを取付ます。

⑤ Install EX #phi#5 ball to the servo horn.

⑦ 送信機のエンコンスティックをフルハ

イにした時、スロットルレバーがフル

ハイになるように、エンコンロツトの

長さを調整します。

⑦ Adjust the length of the engine control rod

so that the throttle lever is at Full High

when the engine control stick of the

transmitter is adjusted to Full High.

⑧ 送信機のエンコンスティックをスロー

にし、エンコントリムをスローにした

とき、スロットルレバーが完全にス

ロー側になるように、送信機

フタバ ATV

JR TRVL ADJ

サンク EPA

スローの数値で合わせてください。

標準値 70%〜80%

⑧ Adjust the transmitter values (FUTABA

ATV, JR TAJ, SANK EPA) so that the

throttle lever is precisely at Slow position

when the engine control stick of the

transmitter is at Slow and the engine

control trim is adjusted to Slow.

Standard value: 70% - 80%

⑥ エンコンロッドを取付ます。

⑥ Install the engine control stick.

送信機のスティックとトリムとエンコンサーボの動作関係が

下図のようになること。

The relation among the transmitter stick, trim, and engine-control

servo shall be as shown below.

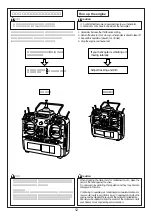

STEP 9-2