HIROSE ELECTRIC CO.,LTD.

ETAD-H0995-00

1

4

/5

FORM HC0011-9-2

△

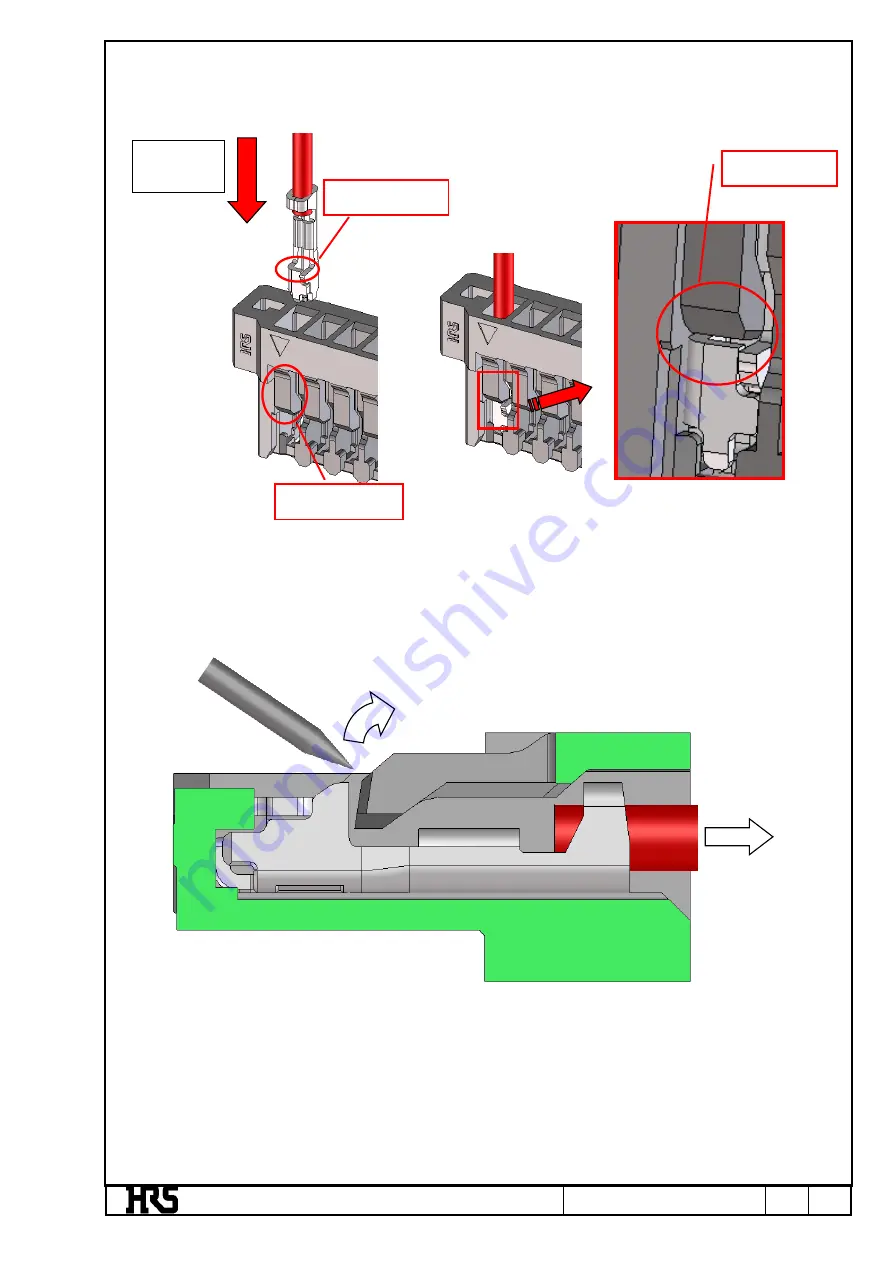

-Make sure that the contact lance is caught by the housing lance of the crimp case.

(Visual check or Slightly pull the terminal to check.)

NOTE: Repairing the crimp contact

For removing the inserted crimp case, lift up the mold lance by using DF-C-PO(B) or a

pointed needle and such, and pull out the cable simultaneously. The repair operation could

make the lance strength lower, therefore, do not reuse the crimp case and replace it to a

new one.

Insertion

direction

1

2

Housing lance

Contact lance

Check point