26

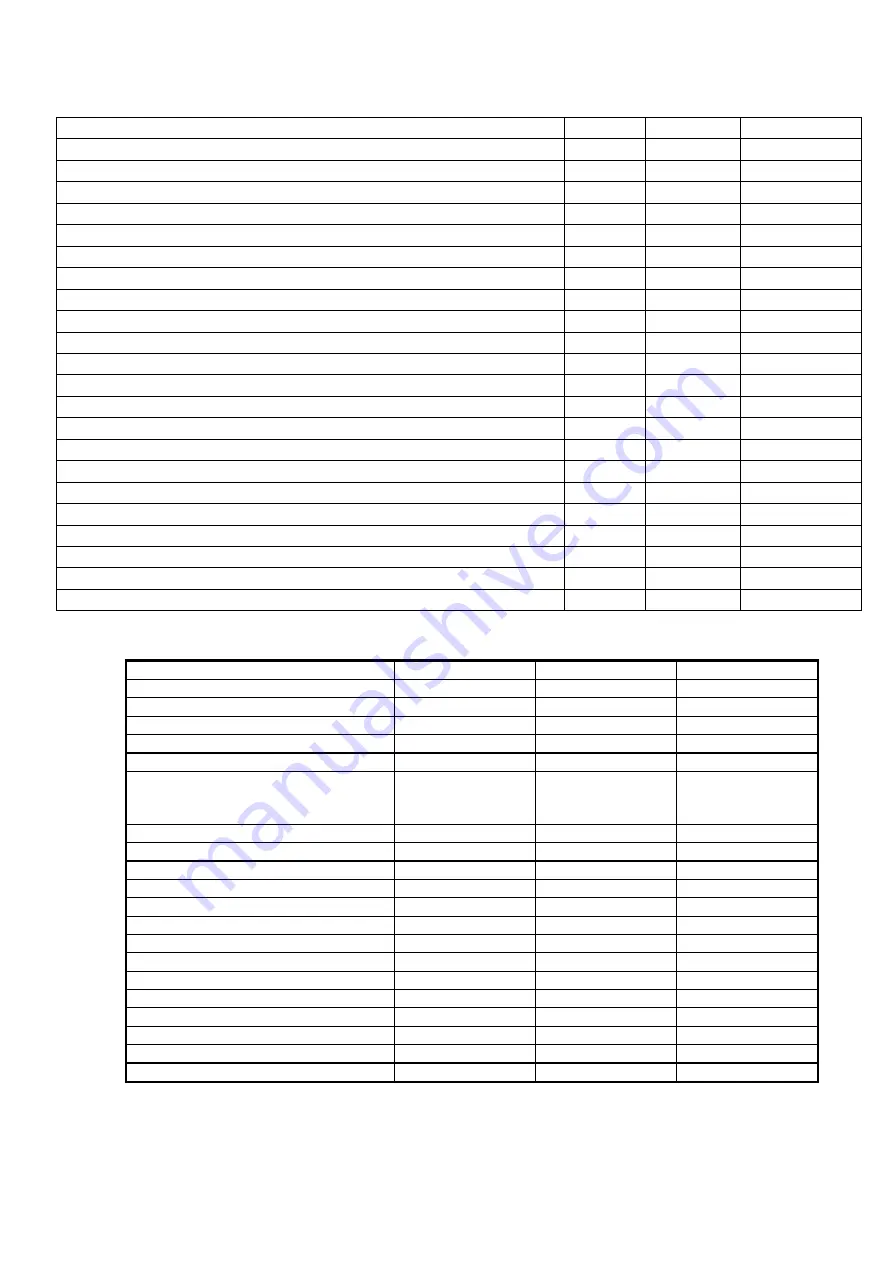

Fastener Description Size Ft. lb

inch/lb

AIR GUIDE ATTACHMENT SCREWS AND BOLTS 6mm

6 Ft.Lbs. 72inch Lbs.

CYLINDER HEAD SCREWS

6mm

8 Ft.Lbs. 96 inch Lbs.

ELECTRONIC IGNITION BOX & IGN. COILS NUTS

6mm

7 Ft.Lbs. 84inch Lbs.

FAN HOUSING MOUNTING SCREWS

6mm

8 Ft.Lbs. 96inch Lbs.

FLYWHEEL DUST COVER (265C1)

6mm

6 Ft.Lbs. 72inch Lbs.

INTAKE MANIFOLD MOUNTING SCREWS

6mm

7 Ft.Lbs. 84inch Lbs.

RECOIL STARTER MOUNTING SCREWS

6mm

8 Ft.Lbs. 96inch Lbs.

CRANKCASE ASSEMBLY SCREWS

8mm

19 ft.Lbs. 228inch Lbs.

FAN PULLEY MOUNTING SCREWS

8mm

19 ft.Lbs. 228 inch Lbs.

ELECTRIC STARTER MOUNTING SCREWS

8mm

19Ft.Lbs. 228 inch Lbs.

CYLINDER BASE NUTS

8mm

19Ft.Lbs. 228 inch Lbs.

EXHAUST MANIFOLD MOUNTING SCREWS

8mm

19ft.Lbs.

228 inch Lbs.

EXHAUST “U” CLAMP NUTS

8mm

17Ft.Lbs. 204 inch Lbs.

GEARBOX DRAIN PLUGS (G-40 GEARBOX)

12mm

10Ft.Lbs. 120 inch Lbs.

CARBURETOR RUBBER INTAKE FLANGE SCREWS

8mm

8Ft.Lbs.

96 inch Lbs.

COOLING FAN MOUNTING NUT

10mm

37Ft.Lbs. 444 inch Lbs.

REDUCTION DRIVE MOUNTING SCREWS

10mm

37Ft.Lbs. 444 inch Lbs.

SPARK PLUGS (cold engine)

10mm

9Ft.Lbs. 108 inch Lbs.

CRANKSHAFT BOLT (PTO-end) (

½

inch NF)

½” NF

46Ft.Lbs. 552 inch Lbs.

CRANKSHAFT NUT(Magneto end)

16mm

107Ft.Lbs

ENGINE MOUNTING BOLTS

10nn

37Ft.Lbs. 444 inch Lbs.

HIRTH ENGINE SETTING VALUES

Engine

F-23 VM slide carb F-23 BN carb

F-23 E (Fuel Inj)

Ign.Timing@2000 - carbureted

16 deg.

16 deg.

Ign.Timing@2000 - Fuel injected

18 deg.

Spark Plug Heat Vl.

280

280

280

Spark Plug Gap

.030

.030

.030

No. of Carburetors/Injectors

Two

Two

2 injectors

Carburetor ID #

Mikuni

VM 34

389-2

Mikuni

BN 34

34-6

Main Jet

180

117.5 High Speed

Needle Jet

166P4

67.5 Low speed

Jet Needle

6DH3 1

st

clip pos.

Idle jet

25

Do Not Exceed RPM

6350

6350

6350

Peak HP RPM

6150

6150

6150

HP @ Peak RPM

–

Free air cooled

50

50

50

Peak Torque RPM

6150

6150

6150

Peak Torque Ft.Lb.

42

42

42

Maximum CHT

535

535

535

Maximum EGT

–

at full power

1256

1256

1256

Operating EGT

–

at full power Rpm

1080 - 1150

1080 - 1150

1080 - 1150

Maximum EGT

–

at cruise Rpm

1330

1330

1330

Operating EGT

–

at cruise Rpm

1180-1250

1180-1250

1180-1250

At time of maintenance, checks, if any item or system is found not to be in top condition, repair or replace the

item as appropriate.

If operated in dusty or sandy conditions, these inspections and maintenance procedures need to be performed

more frequently than listed.

When a gasket is removed, it must be replaced and the bolts must be re-torqued after 2 hours of operation.

Summary of Contents for F-23

Page 17: ...17 Note 1 inch 25 4 millimeters ...

Page 23: ...23 ...