2

2

.

.

S

S

P

P

E

E

C

C

I

I

F

F

I

I

C

C

A

A

T

T

I

I

O

O

N

N

S

S

3

2-1-2.INDOOR UNIT

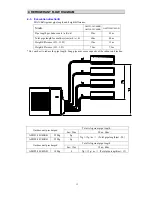

NOTE :Test conditions

:

Cooling : Indoor: DB27

℃

/ WB19

℃

Outdoor: DB35

℃

/ WB24

℃

Heating:

Indoor: DB20

℃

/ WB15

℃

Outdoor: DB7

℃/

WB 6

℃

Model AMS-09UR4SNZA2

AMS-12UR4SNZA2

Function Cooling

Heating

Cooling

Heating

Power supply

a.c 220V~230V/50Hz

Capacity kW

2.6

3.0

3.2

3.8

Dehumidification

l

/h

1.1 1.1 1.4 ----

Capacity

Air flow

m3/h

420

520

450

560

Running current

A

0.18

0.18

0.18

0.18

Rated input

kW

40

40

40

40

Auxiliary heater

A

----

Power factor

%

----

Electrical data

Starting current

A

----

SEER/HSPF ----

Model ----

Compressor

Winding resistance (at25

℃)

Ω

----

Model

YYW16-4-532

YYW16-4-532

Indoor

fan motor

Winding resistance (at20

℃)

Ω

M:364;A:400.5; M:364;A:400.5;

Model

----

Outdoor

fan motor

Winding resistance (at20

℃)

Ω

----

Net size

L

×

W

×

H

cm

75×25×19

75×25×19

Package size

L

×

W

×

H

cm

84×31×27

84×31×27

Net weight

kg

8.0 8.0

Gross weight

kg

9.5 9.5

Liquid pipe

mm

6.35

Gas pipe

mm

9.52

Refrigerant

piping

Connection method

----

Air direction

6

6

Sound level (Hi)

dB

37

37

Fan speed (Hi)

rpm

1200

1300

Fan speed regulator

Refrigerant filling

capacity(R410a)

kg ----

Special

remarks

Throttle mode

----