△

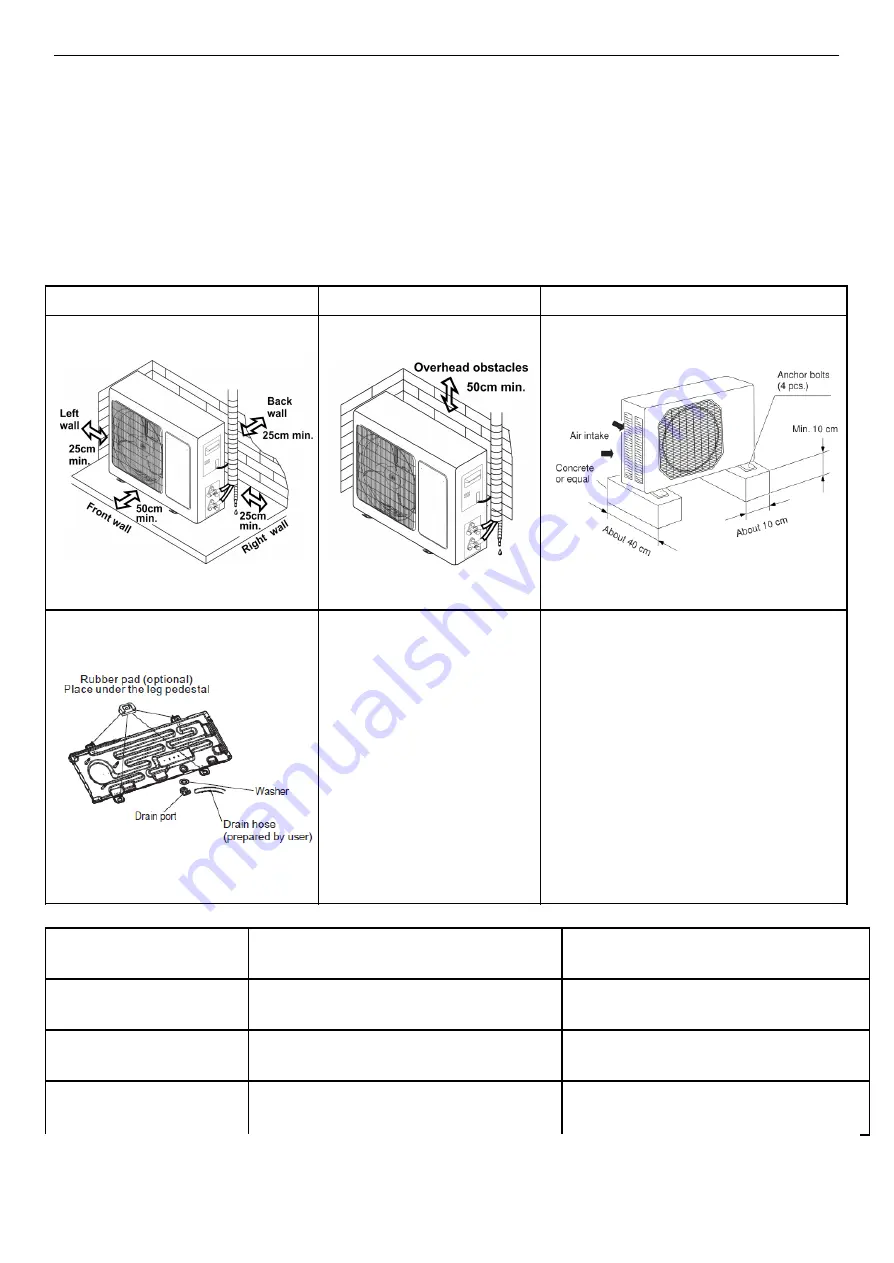

Choose a place as cool as possible.

△

Choose a place that is well ventilated.

△

Allow enough room around the unit for air intake or exhaust and possible maintenance. (see a1,

b1 & c1)

△

Provide a solid base (level concrete pad, concrete block, 10 × 40 cm beams or equal), a

minimum of 10 cm above ground level to reduce humidity and protect the unit against possible

water damage

and decreased service life.

△

If the installation bag has rubber pads, it is strongly recommended for use to reduce vibration

and noise.

△

Use lug bolts or equal to bolt down unit, reducing vibration and noise.

a1

b1

c1

Recommended Wire Diameter:

Capacity size

Wire Diameter(mm

2

)

Fuse or Circuit Breaker Capacity

5K~12k

1.0(Power wire)/1.0

(

Connect wire

)

3.15A

(

indoor

)

/15A

(

outdoor

)

18k

2.5(Power wire)/1.5

(

Connect wire

)

3.15A

(

indoor

)

/20A

(

outdoor

)

22K~30K

2.5(Power wire)/2.5

(

Connect wire

)

3.15A

(

indoor

)

/30A

(

outdoor

)

17

Summary of Contents for AS-09TR2SYDDC01

Page 13: ...View Model R2 View 3 2 Product dimensions Indoor units 13...

Page 19: ...1802900 1902289 19...

Page 20: ...1854605 1861005 20...

Page 21: ...1867560 1875124 21...

Page 22: ...1874568 1847397 22...

Page 23: ...1852066 Outdoor 1507746 23...

Page 24: ...1826526 1854707 24...

Page 25: ...1877957 1852132 25...

Page 26: ...1854446 4 3 Refrigerant Flow System 26...

Page 31: ...J1 06 31...

Page 32: ...R1 01 32...

Page 33: ...33...

Page 34: ...R2 01 Function Instruction 34...

Page 45: ...1916682 45...

Page 47: ...Model of outdoor 1555069 1887379 47...

Page 48: ...1841765 48...

Page 50: ...1952498 50...

Page 78: ...2 DC Fan test point 78...

Page 79: ...3 4 79...

Page 80: ...5 80...

Page 81: ...81...

Page 82: ...DC fan motor test point 82...

Page 83: ...AC voltage test point Sensor test point 6 83...

Page 84: ...test point Check the screw of IPM fastening test point Forward of IPM P U P V P W test 84...

Page 86: ...test point The resistance of the compressor U W V W 7 SI and N test point 86...

Page 87: ...87...