Summary of Contents for AS-09TR2SYDDC01

Page 13: ...View Model R2 View 3 2 Product dimensions Indoor units 13...

Page 19: ...1802900 1902289 19...

Page 20: ...1854605 1861005 20...

Page 21: ...1867560 1875124 21...

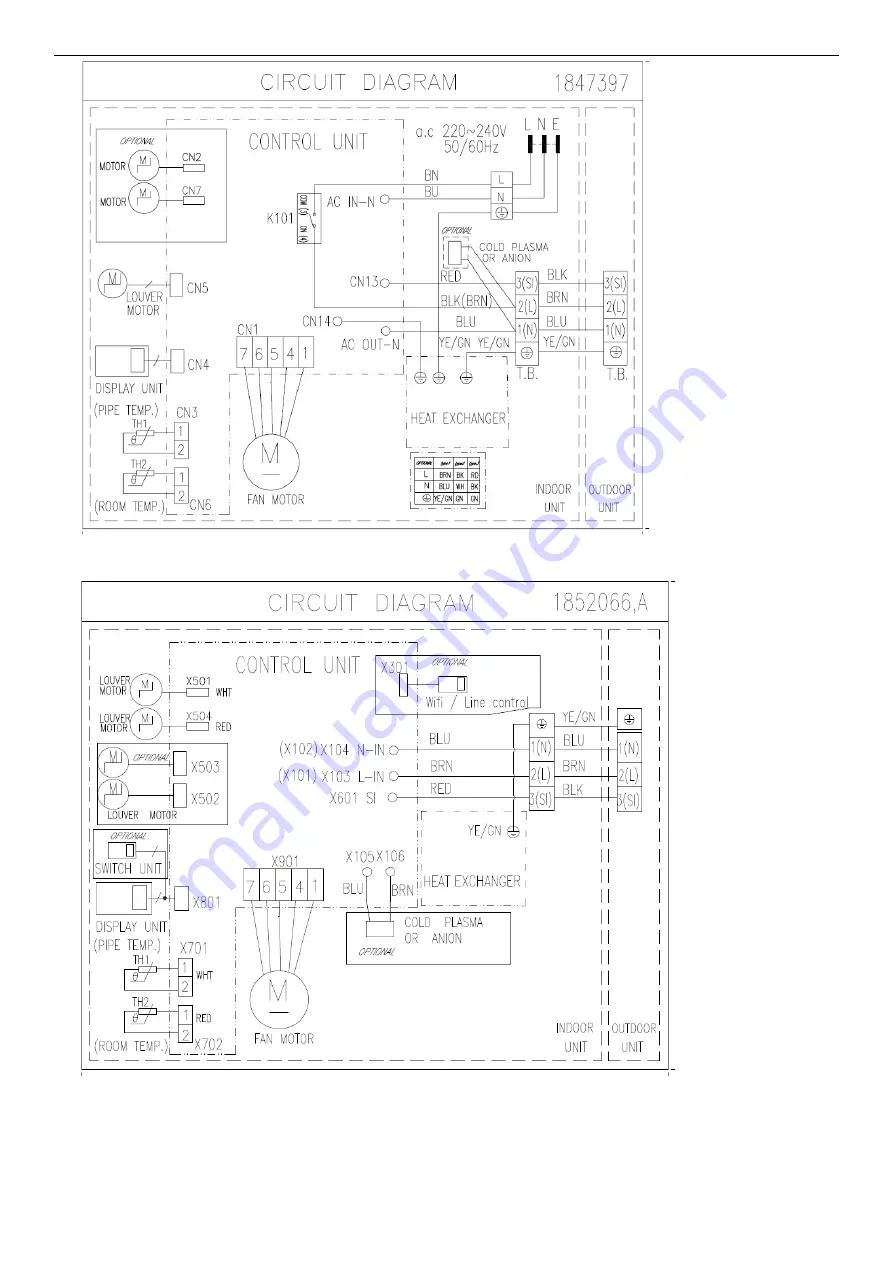

Page 22: ...1874568 1847397 22...

Page 23: ...1852066 Outdoor 1507746 23...

Page 24: ...1826526 1854707 24...

Page 25: ...1877957 1852132 25...

Page 26: ...1854446 4 3 Refrigerant Flow System 26...

Page 31: ...J1 06 31...

Page 32: ...R1 01 32...

Page 33: ...33...

Page 34: ...R2 01 Function Instruction 34...

Page 45: ...1916682 45...

Page 47: ...Model of outdoor 1555069 1887379 47...

Page 48: ...1841765 48...

Page 50: ...1952498 50...

Page 78: ...2 DC Fan test point 78...

Page 79: ...3 4 79...

Page 80: ...5 80...

Page 81: ...81...

Page 82: ...DC fan motor test point 82...

Page 83: ...AC voltage test point Sensor test point 6 83...

Page 84: ...test point Check the screw of IPM fastening test point Forward of IPM P U P V P W test 84...

Page 86: ...test point The resistance of the compressor U W V W 7 SI and N test point 86...

Page 87: ...87...