5

5

.

.

E

E

L

L

E

E

C

C

T

T

R

R

I

I

C

C

A

A

L

L

D

D

A

A

T

T

A

A

78

DC INVERTER AIR CONDITIONER TECHNICAL& SERVICE MANUAL V3.3

78

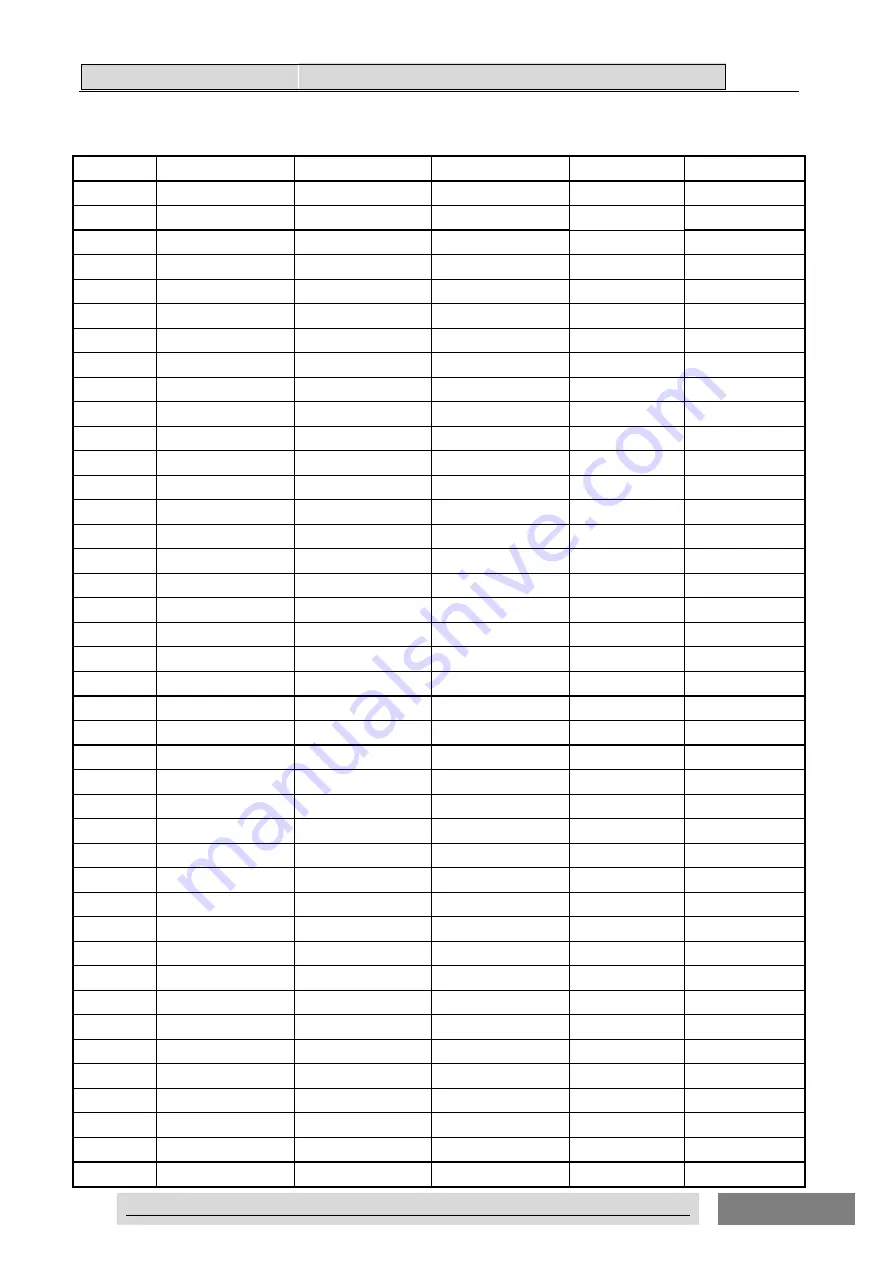

2. THE PARAMETER OF THE OTHER SENSOR IN INDOOR AND OUTDOOR UNIT

:

(

R

0

=15K

±

2%

;

B0/100=3450K

±

2%

)

T [

℃

]

Rmin [ K

Ω

]

Rnom [ K

Ω

]

Rmax [ K

Ω

]

DR(MIN)% DR(MAX)%

-30

60.78

64.77

68.99

-6.16

6.12

-29

57.75

61.36

65.16

-5.88

5.83

-28

54.89

58.15

61.58

-5.61

5.57

-27

52.19

55.14

58.23

-5.35

5.31

-26

49.63

52.30

55.08

-5.11

5.05

-25

47.21

49.62

52.13

-4.86

4.81

-24

44.92

47.10

49.37

-4.63

4.60

-23

42.76

44.73

46.78

-4.40

4.38

-22

40.71

42.49

44.34

-4.19

4.17

-21

38.77

40.38

42.05

-3.99

3.97

-20

36.93

38.39

39.90

-3.80

3.78

-19

35.18

36.51

37.87

-3.64

3.59

-18

33.53

34.74

35.97

-3.48

3.42

-17

31.96

33.06

34.17

-3.33

3.25

-16

30.48

31.47

32.49

-3.15

3.14

-15

29.07

29.97

30.89

-3.00

2.98

-14

27.73

28.56

29.39

-2.91

2.82

-13

26.46

27.22

27.98

-2.79

2.72

-12

25.26

25.95

26.64

-2.66

2.59

-11

24.11

24.75

25.38

-2.59

2.48

-10

23.03

23.61

24.19

-2.46

2.40

-9

21.99

22.53

23.06

-2.40

2.30

-8

21.01

21.51

22.00

-2.32

2.23

-7

20.08

20.54

20.99

-2.24

2.14

-6

19.19

19.62

20.04

-2.19

2.10

-5

18.35

18.74

19.14

-2.08

2.09

-4

17.55

17.92

18.29

-2.06

2.02

-3

16.78

17.13

17.48

-2.04

2.00

-2

16.06

16.38

16.71

-1.95

1.97

-1

15.36

15.67

15.98

-1.98

1.94

0

14.70

15.00

15.29

-2.00

1.90

1

14.08

14.36

14.64

-1.95

1.91

2

13.48

13.75

14.02

-1.96

1.93

3

12.91

13.17

13.43

-1.97

1.94

4

12.36

12.62

12.87

-2.06

1.94

5

11.85

12.09

12.34

-1.99

2.03

6

11.35

11.59

11.83

-2.07

2.03

7

10.88

11.11

11.35

-2.07

2.11

8

10.43

10.66

10.89

-2.16

2.11

9

9.999

10.230

10.450

-2.26

2.11

10

9.590

9.816

10.040

-2.30

2.23