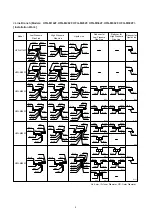

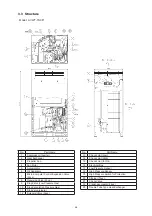

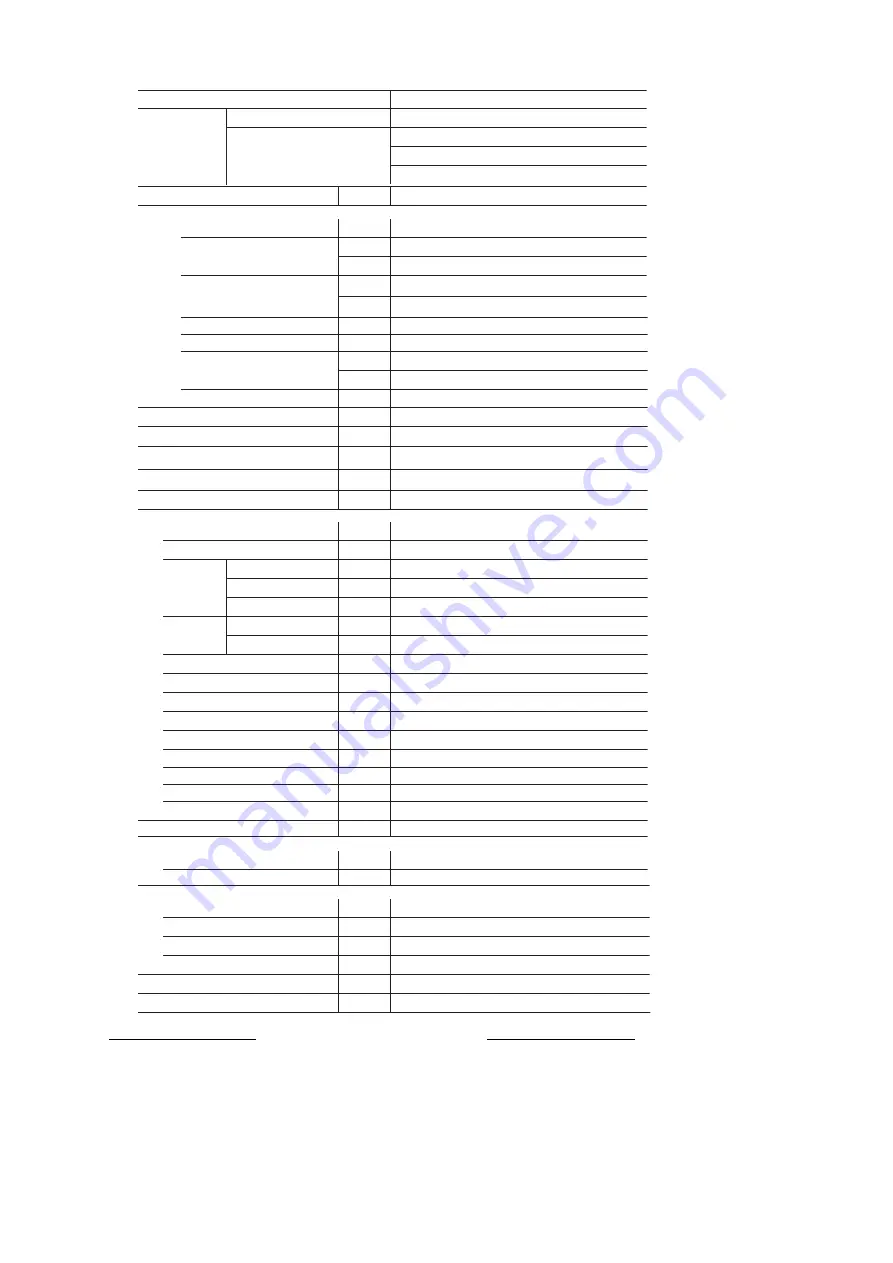

454Model

AVWT-454

FESZA

AVWT-

154FESSA

AVWT-

154FESSA

AVWT-

154FESSA

Ὄ

ą

_

L8

3.5

#UVI

464

2

L8

140.4

#UVI

479

045

L8

39.48

ą

_

L8

150.0

#UVI

51

1

9

L8

37.50

68

/

63

Ὄ

NN

NN

LH

954

(

990

)

L8

'7$%

-

17.1

/

6.6

3"

31.5

LH

86.9

Chargeless Length

N

N

NN

38.1

NN

19.05

.1B

—

N

NJO

585

NJO

NJO

℃

℃

NN

NN

"$´7

~415V

Hz

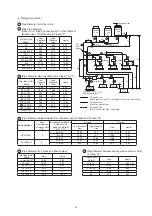

Max.Piping Length

Connections Refrigerant Piping

Refrigerant Flow Control

Capacity

)1Ὀ

Model

Outdoor Model

Power Supply

Power Consumption

Heating Operating Range

Nominal Heating Capacity

Power Consumption

Cabinet Color

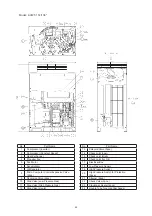

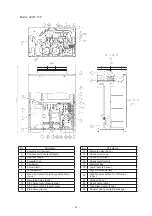

Outer Dimensions (Hx W x D)

Packing Dimensions(H x W x D)

Net Weight(Gross Weight)

Compressor

Crankcase Heater Capacity

Refrigeration

Oil

Type

Brand

Charge(Unit/Comp.)

Refrigerant

Type

Hole for Power Supply Wiring

Hole for Control Line Wiring

Condenser Fan Quantity

Air Flow Rate

Ivory White

Micro-computer Control Expansion Valve

Multi-Pass Cross-Finned Tube

The above cooling and heating capacities show the capacities when the outdoor unit is operated with the 100% rating of indoor units,

Cooling Operation Conditions

Indoor Air Inlet Temperature:

27

℃

DB (80

o

F DB)

※

1 19

℃

WB (66.2

°

F WB)

※

2 19.5

℃

WB (66°F WB)

Heating Operation Conditions

Indoor Air Inlet Temperature: 20

o

C DB (68

o

F DB)

Outdoor Air Inlet Temperature: 7

o

C DB (45

o

F DB)

6

o

C WB (43

o

F WB)

Outdoor Air Inlet Temperature: 35

o

C DB (95

o

F DB)

Piping Length: 7.5 Meters, Piping Lift: 0 Meter

※

3: The sound pressure is tested according to the appendix B of GB/T18836-2002. The above parameters were measured in an

anechoic chamber with no echo, so the echo should be considered in the field. When return air grille is on bottom plate of the

duct or external static pressure is higher, the sound pressure will increase according to the installation method and building structure.

※

4: Max. additional refrigerant charge quantity has included the outdoor unit refrigerant charge Before Shipment

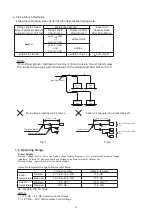

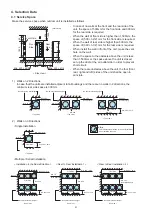

Conbination

Performance

Refrigerating Installation

Pressure(High/Low Pressure)

Mininum Defrosting

time

Max.Defrosting time

Defrosting Start Temp

Defrosting end Temp(Tube)

Fan

Defrosting Condition

Scroll Comp

Idemitsu Kosan

Brazing

With Air Temperature Ta Calculate

With Air Temperature Ta Calculate

Cooling Operating Range

Nominal Cooling Capacit

y

Ą

Nominal Cooling Capacit

y

Ą

Charge Amount

Max Refrigerant Charge Amount

Ą

Heat Exchanger Type

Low

Gas Pipe

Liquid

Pipe

L

Sound Pressure Level(380/208V/Night-Shift)

※

3

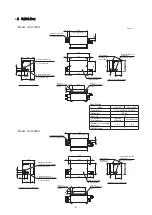

E# "

17

2

0×(1

210

+

1210+1210

)×750

1

8

82

×(1

278+1278+1278

)×

82

8

NN

31.75

High

Gas Pipe

18