7. Refrigerant Piping Work

•

The pressure for this product is 4.15MPa. The pressure required for refrigerant R410A is 1.4 times

higher than the refrigerant R22. Therefore, the refrigerant pipes for R410A must be thicker

than that

for R22. Make sure to use specified refrigerant pipes. Otherwise, the refrigerant pipes

may rupture

due to an excessive refrigerant pressure. Pay close attention to the pipes thickness when using

copper refrigerant pipes. The thickness of copper refrigerant pipes differs depending on its

material.

•

Check to ensure that no pressure exists inside the stop valve before removing the closing pipe

(piping cap).

•

Ensure that the corresponding pipe connections for the liquid, low pressure gas and high/low

pressure

gas

piping

are

properly

connected

to

the

equipment,

as

specifie

d

in

the

installation

instructions.

•

When handling the refrigerant, be sure to wear leather gloves to prevent injuries.

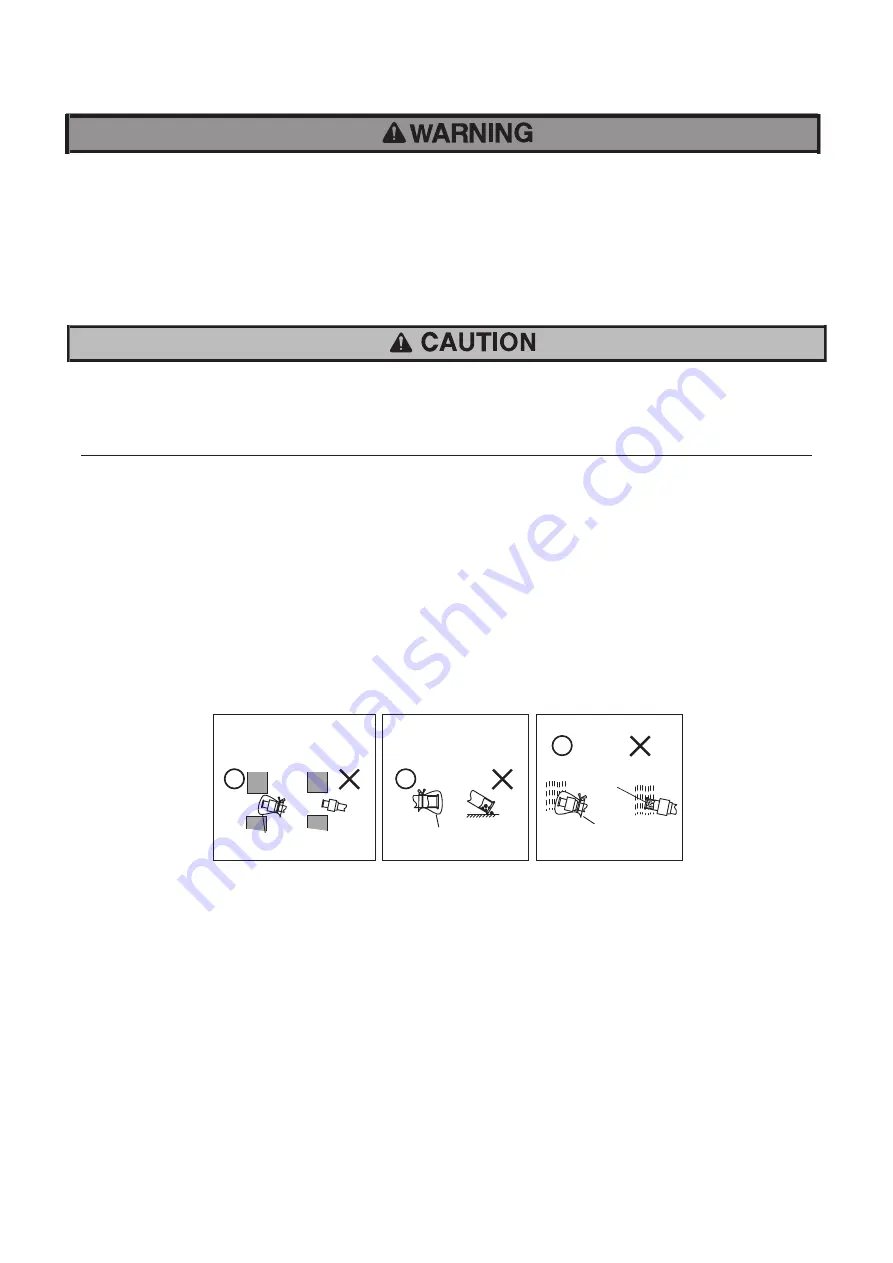

Cautions for Refrigerant Pipe Ends

7.1 Piping Materials

(1) Obtain locally-supplied copper pipes.

(2) Use copper pipe for refrigerant piping.

(3) Pay close attention to pipe thickness.

(4) Use clean copper pipes. Make sure there is no dust or moisture inside the pipes.

Do not use any tools which produce a lot of metal shavings such as a saw or a grinder.

(5) Take special care to prevent contamination or moisture settling on interior pipe surfaces during piping

work.

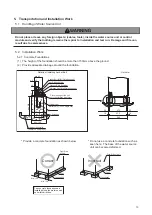

When installing pipe through

the wall, secure a cap at the

end of the pipe.

Correct

Correct

Incorrect

Incorrect

Correct

Incorrect

Hole

Hole

Attach a cap

or vinyl tape.

Attach a cap

or vinyl tape.

Attach a cap

or vinyl bag with

rubber band.

Do not place the pipe

directly on the ground.

Rain water

can enter.

22

Summary of Contents for AVWW-114FKFW

Page 2: ......