44

9. Additional Refrigerant Charge

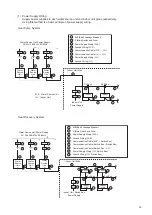

9.1 Leak Test

(1) Check to ensure that the stop valves for high/low pressure gas, low pressure gas and liquid pipes are

closed completely before leak testing.

(2) The refrigerant used for this water source unit is R410A. Use the manifold gauge and the charging

hose for exclusive use of R410A.

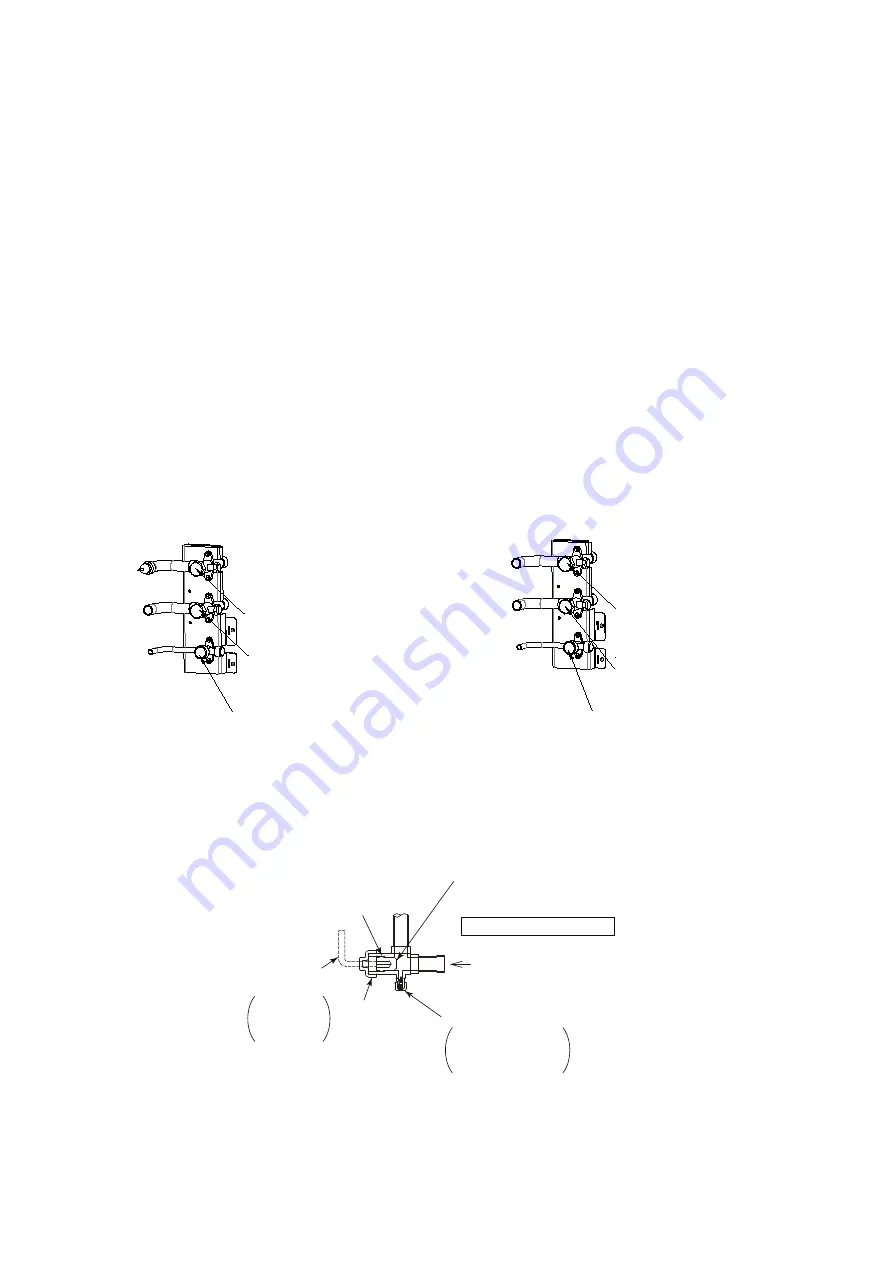

Tightening Check of Stop Valves

After connecting the pipe, remove the caps of stop valves for high/low pressure gas, low pressure gas

(for heat recovery system only) and liquid. Tighten the open-close stop valve in the closing direction

according to the following tightening torque.

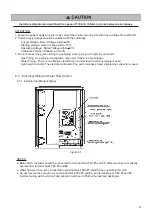

Operation of Stop Valves Caution

(a) Remove the stop valve caps before performing the airtight test after connecting the refrigerant

piping. Tighten the stop valve in clockwise direction.

(b) Perform the work after warming the stop valve with a hair dryer etc. when controlling the stop valve

in a cold area. (The stop valve O-ring will harden at low temperature, causing the O-ring material to

contract by volume, and refrigerant leakage can occur.)

(c) Do not apply excessive force after fully opening the stop valve (Tightening Torque: < 5.0 N·m).

(A back seat (hard stop), is not provided, allowing complete removal of the valve stem.)

(d) Securely tighten the caps according to the torque specifications in Section 7.2.1 after each stop

valve is opened.

Refrigerant

Pressure

Stop Valve

Counterclockwise...Open

Clockwise...............Close

Only the charging

hose for R410A

can be connected.

Access Port

Cap

O-ring

(Rubber)

Hexagonal

Wrench

To open or

close the

stop valve

Closed before Shipment

Stop Valve (for Liquid)

Stop Valve (for Gas)

Not Used

Stop Valve (for High/

Low Pressure Gas)

Stop Valve

(for Low

Pressure Gas)

Stop Valve (for Liquid)

Heat Pump System

Heat Recovery System

Fig. 9.1

Fig. 9.2

Summary of Contents for AVWW-114FKFW

Page 2: ......